Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to disable the SRS system.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE FRONT SEAT ASSEMBLY LH

HINT:

Refer to the instructions for Removal of the front seat assembly.

- for Manual Seat: See page

.gif)

- for Power Seat: See page

.gif)

3. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

.gif)

4. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Heater System)

.gif)

5. REMOVE NO. 2 CONSOLE BOX CARPET

.gif)

6. REMOVE CONSOLE BOX ASSEMBLY

.gif)

7. REMOVE AIR CONDITIONING CONTROL ASSEMBLY

.gif)

8. REMOVE FRONT DOOR SCUFF PLATE LH

.gif)

9. REMOVE COWL SIDE TRIM SUB-ASSEMBLY LH

.gif)

10. REMOVE LOWER NO. 1 INSTRUMENT PANEL FINISH PANEL

.gif)

11. REMOVE FRONT DOOR SCUFF PLATE RH

.gif)

12. REMOVE COWL SIDE TRIM SUB-ASSEMBLY RH

.gif)

13. REMOVE NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

14. REMOVE LOWER INSTRUMENT PANEL SUB-ASSEMBLY

.gif)

15. REMOVE SHIFT LEVER KNOB SUB-ASSEMBLY

.gif)

16. REMOVE POSITION INDICATOR HOUSING ASSEMBLY

.gif)

17. REMOVE CONSOLE BOX SUB-ASSEMBLY

.gif)

18. SEPARATE PARKING BRAKE PEDAL ASSEMBLY

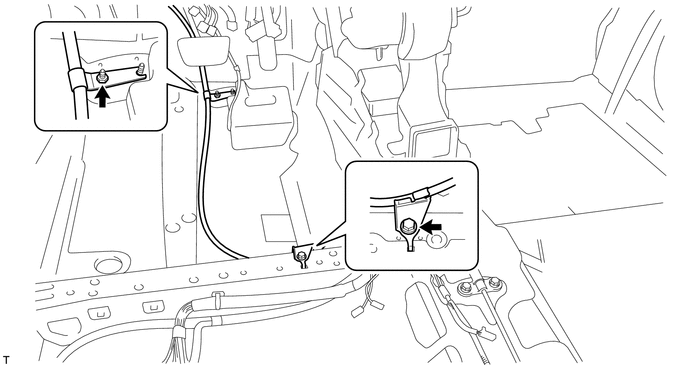

(a) Turn back the floor carpet.

|

(b) Disconnect the heated oxygen sensor connector and disengage the 2 clamps (for 2GR-FE). |

|

(c) Remove the bolt and nut, and separate the No. 1 parking brake cable assembly from the body.

|

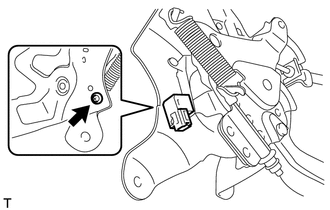

(d) Disconnect the parking brake switch connector. |

|

|

(e) Remove the 3 nuts and separate the parking brake pedal assembly from the body. |

|

19. REMOVE PARKING BRAKE SWITCH ASSEMBLY

|

(a) Remove the screw and parking brake switch assembly. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT PARKING BRAKE SWITCH ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester ...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT OUTER MIRROR SWITCH ASSEMBLY (w/o Memory)

(a) The L position of the left/right adjustment switch: Measure the resistance

according to the value(s) in the table below.

Standard Resistance (for Left Side):

Tes ...

System Description

SYSTEM DESCRIPTION

1. GENERAL

(a) Deceleration sensors used for the airbag system are installed on various

parts on the vehicle and calculate the deceleration rate of each part during a collision.

(b) Depending on the situation, the center airbag sensor a ...

0.1249

.png)

.png)

.png)