Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL LH

2. REMOVE FRONT FENDER OUTSIDE MOULDING LH

.gif)

3. REMOVE FRONT FENDER LINER LH

|

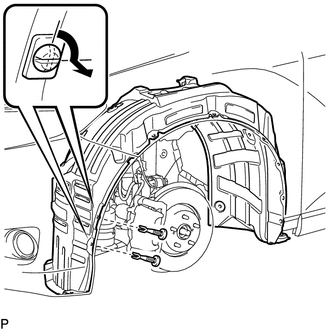

(a) Using a screwdriver, turn the pin 90 degrees and remove the 2 pin hold clips. Text in Illustration

|

|

|

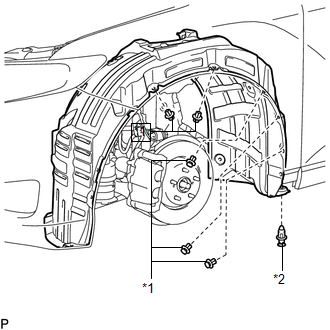

(b) Remove the 5 clips <A>. Text in Illustration

|

|

(c) Remove the clip <B>.

|

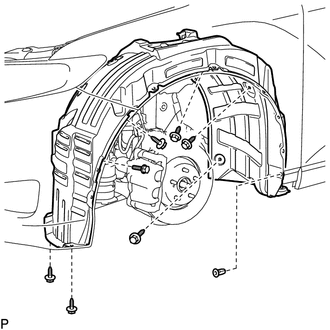

(d) Remove the bolt and 6 screws. |

|

(e) Remove the grommet and front fender liner LH.

HINT:

The grommets need to be replaced with new ones because they will break when they are removed.

4. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

5. REMOVE RADIATOR GRILLE

.gif)

6. REMOVE LOW PITCHED HORN ASSEMBLY

.gif)

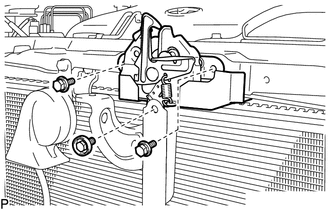

7. REMOVE HOOD LOCK ASSEMBLY (w/o Engine Hood Courtesy Switch)

|

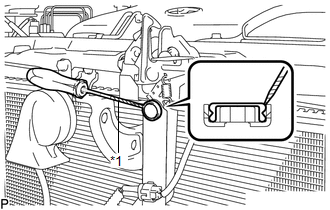

(a) Using a screwdriver, remove the hood lock nut cap. Text in Illustration

HINT: Tape the screwdriver tip before use. |

|

|

(b) Remove the 3 bolts. |

|

|

(c) Disconnect the hood lock control cable and remove the hood lock assembly. |

|

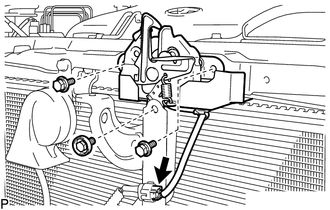

8. REMOVE HOOD LOCK ASSEMBLY (w/ Engine Hood Courtesy Switch)

|

(a) Using a screwdriver, remove the hood lock nut cap. Text in Illustration

HINT: Tape the screwdriver tip before use. |

|

|

(b) Disconnect the connector. |

|

(c) Remove the 3 bolts.

|

(d) Disconnect the hood lock control cable and remove the hood lock assembly. |

|

9. REMOVE FRONT DOOR SCUFF PLATE LH

.gif)

10. REMOVE COWL SIDE TRIM SUB-ASSEMBLY LH

.gif)

11. REMOVE LOWER NO. 1 INSTRUMENT PANEL FINISH PANEL

.gif)

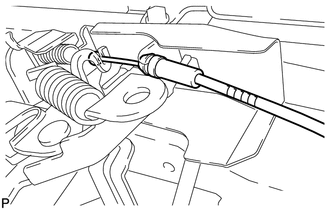

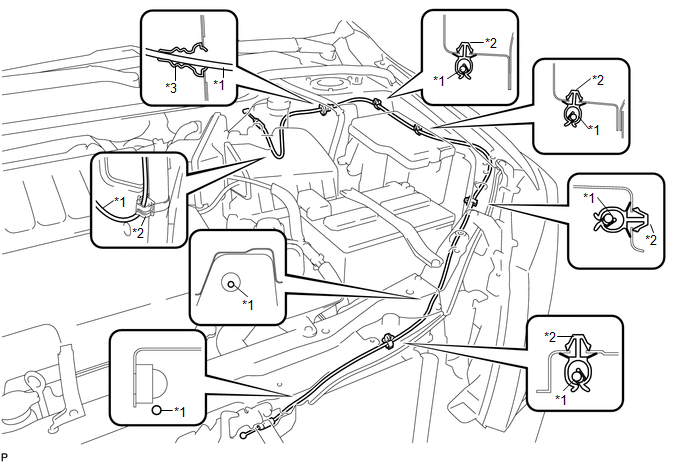

12. REMOVE HOOD LOCK CONTROL CABLE ASSEMBLY

(a) Using a screwdriver, disconnect each clamp shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

Hood Lock Control Cable |

*3 |

Hood Cable Grommet |

|

*2 |

Clamp |

- |

- |

HINT:

Tape the screwdriver tip before use.

(b) Pull the hood lock control cable assembly from the engine compartment and remove it.

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL HOOD LOCK CONTROL CABLE ASSEMBLY

(a) Pass the hood lock control cable assembly into the engine compartment.

(b) Pass the cable through the upper radiator support. ...

Power Back Door Closer Switch

Power Back Door Closer Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

2. REMOVE POWER BACK DOOR CLOSER SWITCH ASSEMBLY

(a) Disconnect the con ...

Other materials about Toyota Venza:

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY)

(a) Disconnect the 2A and 2F main body ECU (driver side junction block assembly)

connectors.

(b) Measure the voltage and resistance according to the value(s) in the table

be ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR SEAT ASSEMBLY RH

(a) Place the rear seat assembly RH in the cabin.

NOTICE:

Be careful not to damage the vehicle body.

(b) Temporarily install the 2 bolts on the front side of the seat.

...

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR DOOR SCUFF PLATE RH

HINT:

Use the same procedure for the RH side and the LH side (See page

).

2. REMOVE REAR DOOR OPENING TRIM WEATHERSTRIP RH

HINT:

Use the same procedure for the RH side and the LH side (See page

). ...

0.135