Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

(See page .gif) ).

).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

3. REMOVE THROTTLE BODY ASSEMBLY

(a) Remove the throttle body assembly (See page

.gif) ).

).

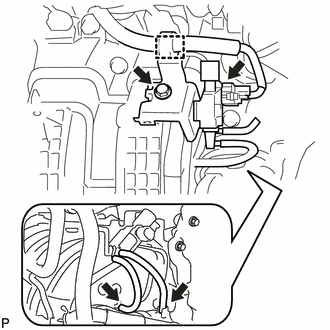

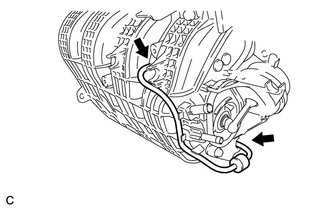

4. REMOVE VACUUM SWITCHING VALVE ASSEMBLY (for ACIS)

|

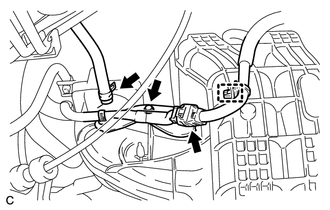

(a) Disconnect the 2 vacuum hoses, 2 union to connector tube hoses, clamp and connector. |

|

(b) Remove the bolt and vacuum switching valve assembly (for ACIS).

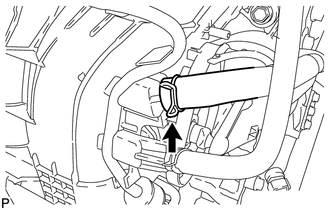

5. DISCONNECT NO. 2 VENTILATION HOSE

|

(a) Disconnect the No. 2 ventilation hose from the intake manifold. |

|

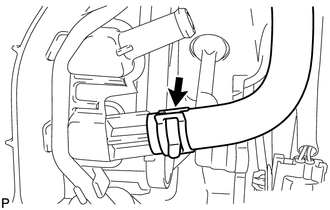

6. REMOVE UNION TO CONNECTOR TUBE HOSE

|

(a) Remove the union to connector tube hose from the intake manifold. |

|

7. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

.gif)

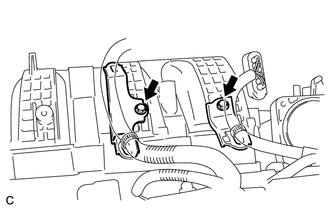

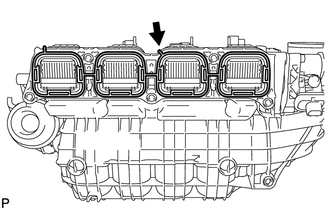

8. REMOVE INTAKE MANIFOLD

|

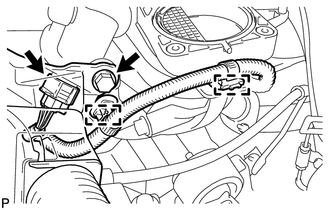

(a) Remove the 2 bolts and 2 wire harness brackets. |

|

|

(b) Disconnect the fuel vapor feed hose, clamp and connector. |

|

(c) Remove the bolt and wire harness bracket.

|

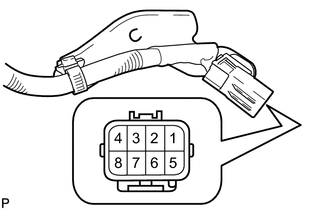

(d) Apply battery voltage to the terminals of the connector to close the tumble control valves. Standard:

NOTICE:

|

|

|

(e) Remove the bolt. |

|

(f) Detach the 2 clamps from the intake manifold and bracket.

(g) Disconnect the intake air control valve actuator connector.

|

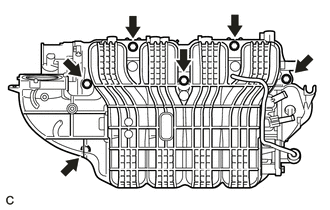

(h) Remove the 6 bolts and intake manifold. NOTICE: The tumble control valves may be damaged if they are not closed before installing the intake manifold. HINT: Connect the battery to the terminals of the actuator to operate the motor

and close the valves (See page |

|

|

(i) Remove the intake manifold gasket from the intake manifold. |

|

9. REMOVE CHECK VALVE

|

(a) Disconnect the 2 vacuum hoses from the intake manifold and remove the check valve. |

|

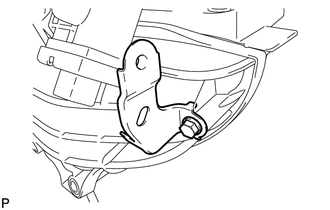

10. REMOVE WIRING HARNESS CLAMP BRACKET

|

(a) Remove the bolt and wiring harness clamp bracket. |

|

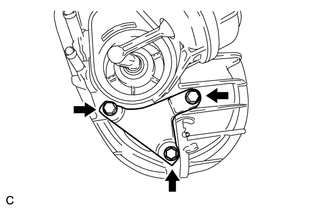

11. REMOVE ENGINE MOUNTING DAMPER

|

(a) Remove the 3 bolts and engine mounting damper. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT INTAKE AIR CONTROL VALVE (for ACIS)

(a) Inspect the diaphragm.

(1) Using a vacuum pump, apply a vacuum of 60 kPa (450 mmHg, 17.7 in.Hg)

or higher to ...

Other materials about Toyota Venza:

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

Sliding Roof (Sliding Roof ECU (Sliding Roof Drive Gear Sub-assembly))

DTC Code

Detection Item

Trouble Area

See page

B2341

Sensor (Motor) Failure

...

Checking Monitor Status

CHECKING MONITOR STATUS

The purpose of the monitor result (mode 06) is to allow access to the results

of on-board diagnostic monitoring tests of specific components/systems that are

not continuously monitored. Examples are catalysts and evaporative emissi ...

Main Body ECU Vehicle Information Reading/Writing Process Malfunction (B15F6)

DESCRIPTION

This DTC is stored when items controlled by the main body ECU (multiplex network

body ECU) cannot be customized via the audio and visual system vehicle customization

screen.

HINT:

The main body ECU (multiplex network body ECU) controls t ...

0.1259