Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for 2WD)

When Not Using the Engine Support Bridge: (See page

.gif) )

)

When Using the Engine Support Bridge: (See page

.gif) )

)

2. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for AWD)

When Not Using the Engine Support Bridge: (See page

.gif) )

)

When Using the Engine Support Bridge: (See page

.gif) )

)

3. REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

|

(a) Using SST, hold the crankshaft pulley. SST: 09213-54015 SST: 09330-00021 HINT: Part number of installation bolt for SST (crankshaft pulley holding tool): 91551-80650 (quantity: 2) |

|

|

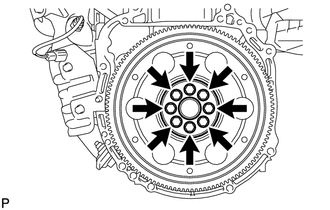

(b) Remove the 8 bolts, front drive plate spacer, drive plate and ring gear sub-assembly, and rear drive plate spacer. |

|

4. REMOVE REAR ENGINE OIL SEAL

|

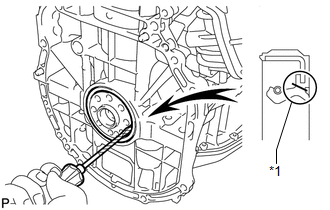

(a) Using a knife, cut off the lip of the oil seal. Text in Illustration

|

|

(b) Using a screwdriver, pry out the oil seal.

HINT:

Tape the screwdriver tip before use.

NOTICE:

Do not damage the surface of the oil seal press fit hole or the crankshaft.

Components

Components

COMPONENTS

ILLUSTRATION

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR ENGINE OIL SEAL

(a) Apply MP grease to the lip of a new oil seal.

NOTICE:

Do not allow foreign matter to contact the lip of the oil seal.

Do not ...

Other materials about Toyota Venza:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE STEERING RACK BOOT CLIP (for LH Side)

(a) Using pliers, remove the steering rack boot clip.

2. REMOVE STEERING RACK BOOT CLIP (for RH Side)

HINT:

Perform the same procedure as for the LH side.

3. REMOVE NO. 2 STEERING RAC ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT INNER REAR VIEW MIRROR ASSEMBLY

(a) Inspect operation of the electrochromic inner mirror.

(1) Connect a positive (+) lead from the battery to terminal 1 and a negative

(-) lead to terminal 2.

(2) Press the AUTO switch.

...

Tire inflation pressure

- Tire inflation pressure

The recommended cold tire inflation pressure and tire size is displayed on the

tire and loading information label.

- Inspection and adjustment procedure

1. Tire valve

2. Tire pressure gauge

Remove the tire val ...

0.1613

.png)