Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

(a) Remove the engine and transaxle (See page

.gif) ).

).

2. REMOVE EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY

(a) Remove the exhaust manifold converter (See page

.gif) ).

).

3. REMOVE THROTTLE BODY ASSEMBLY

.gif)

4. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

.gif)

5. DISCONNECT NO. 2 VENTILATION HOSE

.gif)

6. REMOVE INTAKE MANIFOLD

.gif)

7. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

(See page .gif) )

)

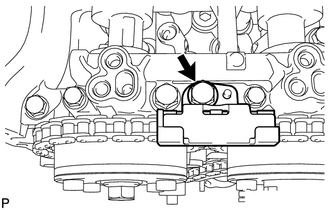

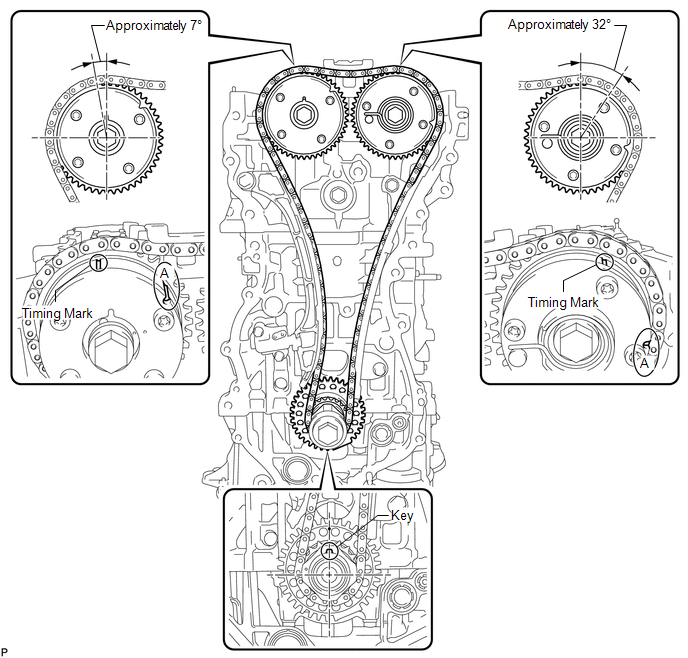

8. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Temporarily install the crankshaft pulley bolt.

HINT:

"A" is not a timing mark.

(b) Rotate the crankshaft clockwise so that the timing marks on the crankshaft timing gear and camshaft timing gears are as shown in the illustration.

HINT:

If the timing marks do not align, rotate the crankshaft clockwise again and align the timing marks.

(c) Remove the crankshaft pulley bolt.

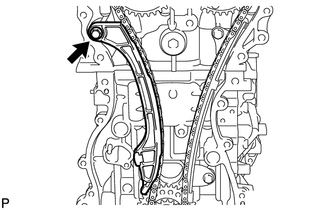

9. REMOVE TIMING CHAIN GUIDE

|

(a) Remove the bolt and timing chain guide. |

|

10. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

|

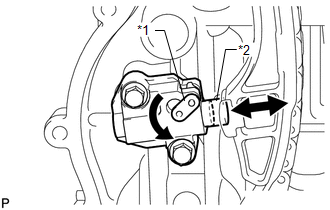

(a) Allow the plunger to extend slightly, and then rotate the stopper plate counterclockwise to release the lock. Once the lock is released, push the plunger into the tensioner. Text in Illustration

|

|

|

(b) Move the stopper plate clockwise to set the lock, and insert a pin into the stopper plate hole. Text in Illustration

|

|

|

(c) Remove the 2 bolts, chain tensioner and gasket. |

|

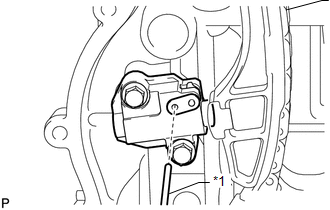

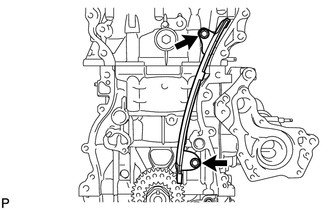

11. REMOVE CHAIN TENSIONER SLIPPER

|

(a) Remove the bolt and chain tensioner slipper. |

|

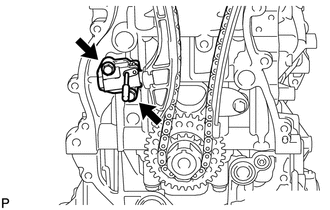

12. REMOVE CHAIN SUB-ASSEMBLY

(a) Remove the chain sub-assembly.

13. REMOVE NO. 1 CHAIN VIBRATION DAMPER

|

(a) Remove the 2 bolts and chain vibration damper. |

|

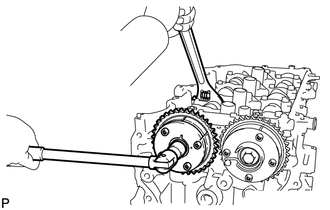

14. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY

|

(a) Hold the hexagonal portion of the camshaft with a wrench and remove the bolt and camshaft timing gear. NOTICE:

|

|

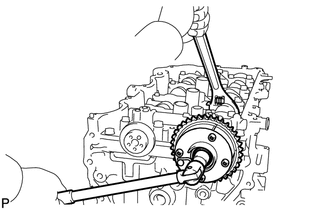

15. REMOVE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

|

(a) Hold the hexagonal portion of the camshaft with a wrench and remove the bolt and camshaft timing exhaust gear. NOTICE:

|

|

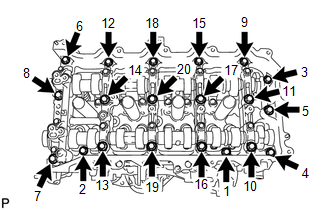

16. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY

|

(a) Uniformly loosen and remove the 20 bearing cap bolts in the sequence shown in the illustration. |

|

|

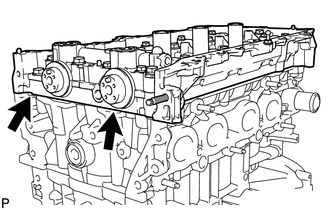

(b) Remove the camshaft housing by prying between the cylinder head and camshaft housing with a screwdriver. HINT: Tape the screwdriver tip before use. NOTICE: Be careful not to damage the contact surfaces of the cylinder head and camshaft housing. |

|

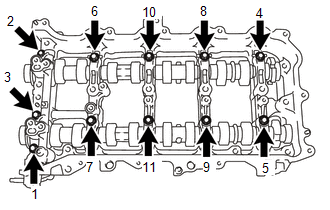

17. REMOVE CAMSHAFT BEARING CAP

|

(a) Remove the 11 bearing cap bolts in the sequence shown in the illustration. |

|

(b) Remove the 5 bearing caps.

HINT:

Arrange the removed parts in the correct order.

18. REMOVE OIL CONTROL VALVE FILTER

.gif)

19. REMOVE NO. 1 CAMSHAFT BEARING

.gif)

20. REMOVE CAMSHAFT

(a) Remove the No. 1 and No. 2 camshafts.

21. REMOVE NO. 2 CAMSHAFT BEARING

.gif)

22. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

(a) Remove the 16 valve rocker arms from the cylinder head.

HINT:

Arrange the removed parts in the correct order.

23. REMOVE VALVE LASH ADJUSTER ASSEMBLY

(a) Remove the 16 valve lash adjusters from the cylinder head.

HINT:

Arrange the removed parts in the correct order.

24. REMOVE VALVE STEM CAP

(a) Remove the 16 valve stem caps from the cylinder head.

HINT:

Arrange the removed parts in the correct order.

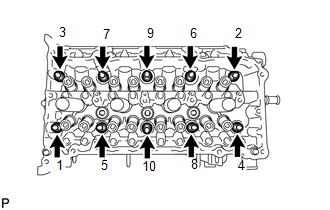

25. REMOVE CYLINDER HEAD SUB-ASSEMBLY

|

(a) Using a 10 mm bi-hexagon wrench, uniformly loosen the 10 bolts in the sequence shown in the illustration. Remove the 10 cylinder head bolts and plate washers. HINT: Be sure to keep the removed parts separate for each installation position. NOTICE:

|

|

(b) Remove the cylinder head.

26. REMOVE CYLINDER HEAD GASKET

(a) Remove the cylinder head gasket from the cylinder block.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the camshaft, No. 2 camshaft,

camshaft timing gear assembly, camshaft timing exhaust gear as ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR WIPER MOTOR AND BRACKET ASSEMBLY

(a) Install the rear wiper motor and bracket assembly with the 3 bolts.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(b) C ...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Removal

REMOVAL

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for 2GR-FE)

See page

2. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for 1AR-FE)

See page

3. REMOVE TRANSFER ASSEMBLY

(a) Remove the 2 bolts and 6 nuts.

...

0.1765