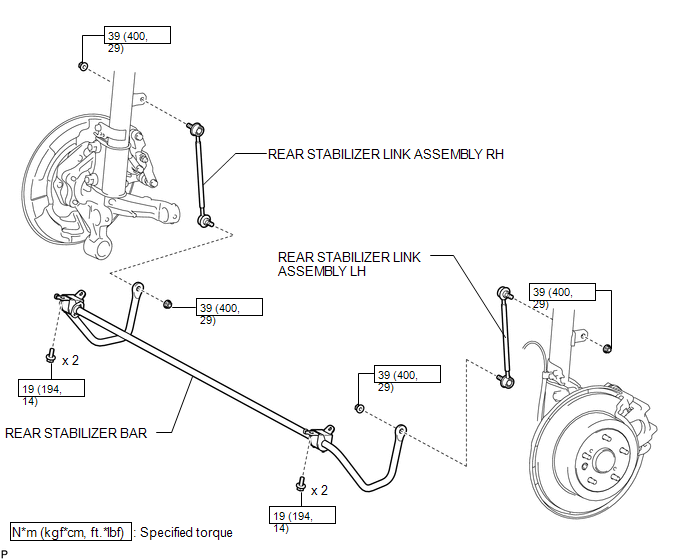

Toyota Venza: Rear Stabilizer Bar(for 2wd)

Components

COMPONENTS

ILLUSTRATION

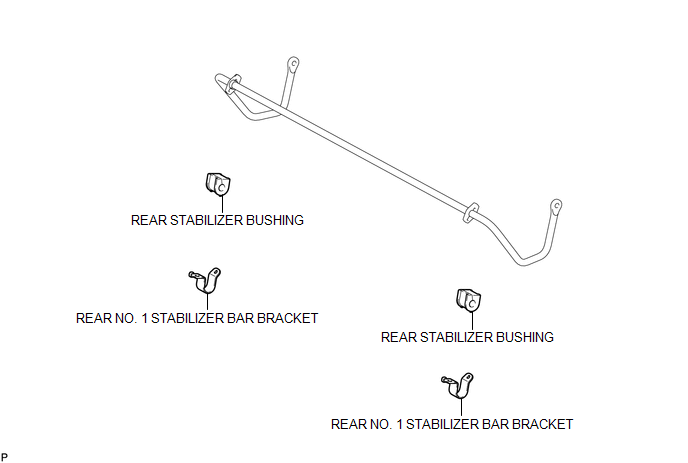

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR WHEELS

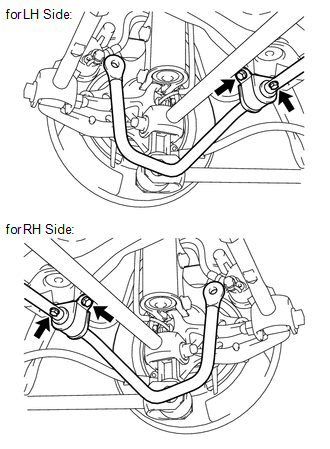

2. REMOVE REAR STABILIZER LINK ASSEMBLY LH

|

(a) Remove the nut and separate the rear stabilizer link assembly LH from the rear stabilizer bar. Text in Illustration

HINT: If the ball joint turns together with the nut, use a hexagon wrench (5 mm) to hold the stud bolt. |

|

|

(b) Remove the nut and the rear stabilizer link assembly LH from the rear shock absorber with coil spring LH. Text in Illustration

HINT: If the ball joint turns together with the nut, use a hexagon wrench (5 mm) to hold the stud bolt. |

|

3. REMOVE REAR STABILIZER LINK ASSEMBLY RH

HINT:

Perform the same procedure as the LH side.

4. REMOVE REAR STABILIZER BAR

|

(a) Remove the 4 bolts and rear stabilizer bar. |

|

5. REMOVE REAR NO. 1 STABILIZER BAR BRACKET (for LH Side)

|

(a) Remove the rear No. 1 stabilizer bar bracket. |

|

6. REMOVE REAR NO. 1 STABILIZER BAR BRACKET (for RH Side)

HINT:

Perform the same procedure as the LH side.

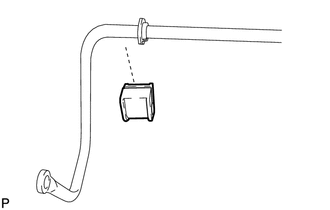

7. REMOVE REAR STABILIZER BUSHING (for LH Side)

|

(a) Remove the rear stabilizer bushing. |

|

8. REMOVE REAR STABILIZER BUSHING (for RH Side)

HINT:

Perform the same procedure as the LH side.

Inspection

INSPECTION

PROCEDURE

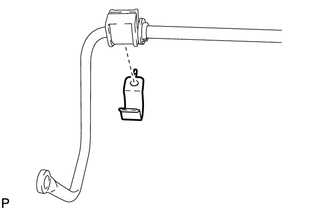

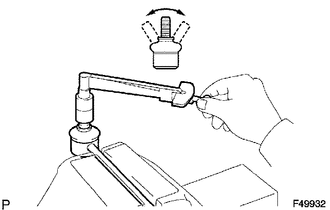

1. INSPECT REAR STABILIZER LINK ASSEMBLY

|

(a) As shown in the illustration, move the ball joint stud back and forth 5 times before installing the nut. |

|

(b) Using a torque wrench, turn the nut continuously at a rate of 3 to 5 seconds per turn and take the torque reading on the fifth turn.

Turning torque:

1.0 N*m (10 kgf*cm, 9 in.*lbf) or less

If the turning torque is not within the specified range, replace the rear stabilizer link assembly with a new one.

(c) Check for any cracks and grease leaks on the ball joint dust cover.

(d) Check that neither unusual drag nor rattle occurs during rotation.

Installation

INSTALLATION

PROCEDURE

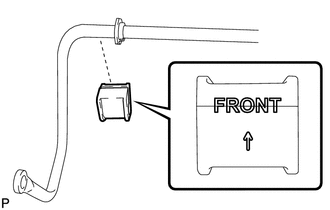

1. INSTALL REAR STABILIZER BUSHING (for LH Side)

|

(a) Install the rear stabilizer bushing. NOTICE: Bushing slit should always face vehicle forwards, even if bushing "FRONT" text does not exist. |

|

2. INSTALL REAR STABILIZER BUSHING (for RH Side)

HINT:

Perform the same procedure as the LH side.

3. INSTALL REAR NO. 1 STABILIZER BAR BRACKET (for LH Side)

|

(a) Install the rear No. 1 stabilizer bar bracket. |

|

4. INSTALL REAR NO. 1 STABILIZER BAR BRACKET (for RH Side)

HINT:

Perform the same procedure as the LH side.

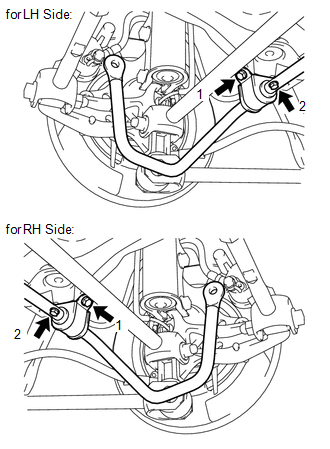

5. INSTALL REAR STABILIZER BAR

|

(a) Install the rear stabilizer bar with the 4 bolts in order 1 to 2. Torque: 19 N·m {194 kgf·cm, 14 ft·lbf} |

|

6. INSTALL REAR STABILIZER LINK ASSEMBLY LH

|

(a) Install the rear stabilizer link assembly LH to the rear shock absorber with coil spring LH with the nut. Text in Illustration

Torque: 39 N·m {400 kgf·cm, 29 ft·lbf} HINT: If the ball joint turns together with the nut, use a hexagon wrench (5 mm) to hold the stud bolt. |

|

|

(b) Install the rear stabilizer link assembly LH to the rear stabilizer bar with the nut. Text in Illustration

Torque: 39 N·m {400 kgf·cm, 29 ft·lbf} HINT: If the ball joint turns together with the nut, use a hexagon wrench (5 mm) to hold the stud bolt. |

|

7. INSTALL REAR STABILIZER LINK ASSEMBLY RH

HINT:

Perform the same procedure as the LH side.

8. INSTALL REAR WHEELS

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

Disposal

Disposal

DISPOSAL

PROCEDURE

1. DISPOSE OF REAR SHOCK ABSORBER

(a) Fully extend the shock absorber piston rod.

(b) Using a drill, make a hole in are ...

Other materials about Toyota Venza:

Brake Warning Light Remains ON

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN communication.

If any of the following is detected, the brake warning light remains on:

The skid control ECU connector is disconnected from the skid control

ECU.

T ...

Customize Parameters

CUSTOMIZE PARAMETERS

1. CUSTOMIZING FUNCTION WITH TECHSTREAM (REFERENCE)

HINT:

When the customer requests a change in a function, first make sure that

the function can be customized.

Be sure to make a note of the current settings before cust ...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

2.

CUSTOMER PROBLEM ANALYSIS

...

0.1207

.png)

.png)

.png)

.png)