Toyota Venza: Purge Valve

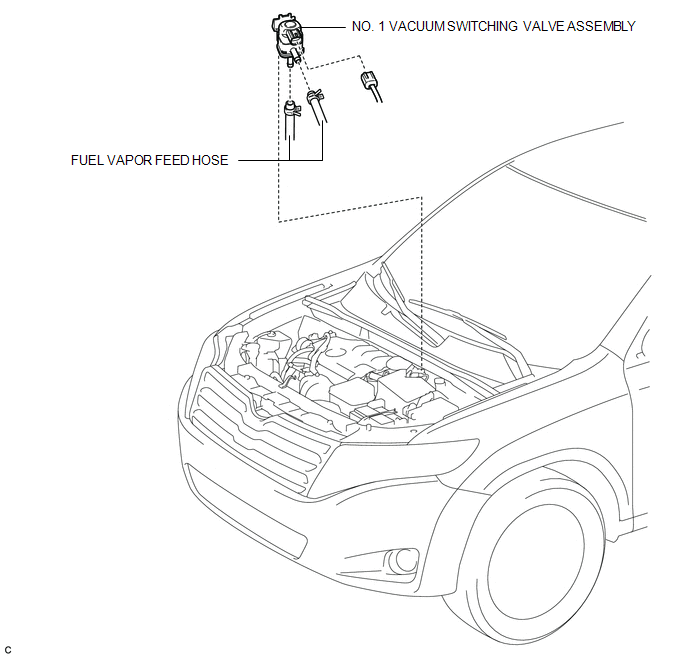

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

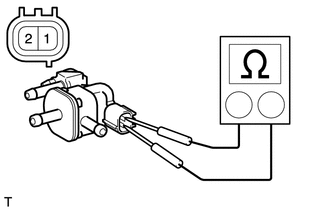

1. INSPECT NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the No. 1 vacuum switching valve assembly. |

|

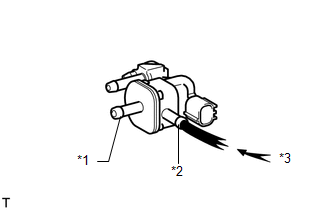

(b) Check the operation of the No. 1 vacuum switching valve assembly.

|

(1) Check that air does not flow from port F when air is applied to port E. Text in Illustration

|

|

|

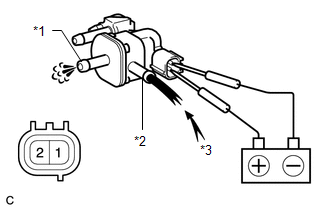

(2) Apply battery voltage to the connector, and check the VSV operation. Text in Illustration

OK:

If the result is not as specified, replace the No. 1 vacuum switching valve assembly. |

|

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

|

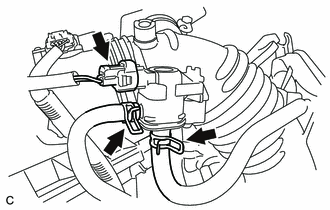

(a) Disconnect the connector and 2 fuel vapor feed hoses. |

|

|

(b) Remove the No. 1 vacuum switching valve assembly. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

|

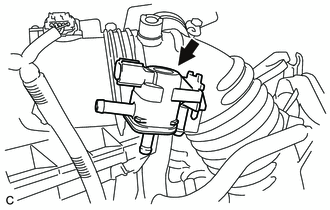

(a) Install the No. 1 vacuum switching valve assembly. |

|

|

(b) Connect the connector and 2 fuel vapor feed hoses. |

|

Pcv Valve

Pcv Valve

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE INTAKE MANIFOLD

(a) Remove the intake manifold (See page ).

2. REMOVE VENTILATION VALVE SUB-ASSEMBLY

( ...

Other materials about Toyota Venza:

Registering ID codes

The tire pressure warning valve and transmitter is equipped with a unique ID

code. When replacing a tire pressure warning valve and transmitter, it is necessary

to register the ID code of tire pressure warning valve and transmitter. Have the

ID code regi ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR SEAT INNER BELT ASSEMBLY LH

(a) Install the rear seat inner belt assembly LH with the bolt.

Text in Illustration

*1

Protruding Part

Torque:

42 NÂ ...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

battery terminal to disable the SRS system (See page

).

NOTICE:

When disconnecting the cable, s ...

0.1812

.png)

.png)