Toyota Venza: Power Back Door cannot be Closed Using the Power Back Door Closer Switch

DESCRIPTION

When the power back door cannot be closed using the power back door closer switch, either of the following may be malfunctioning: 1) power back door closer switch circuit or 2) power back door ECU (power back door motor unit).

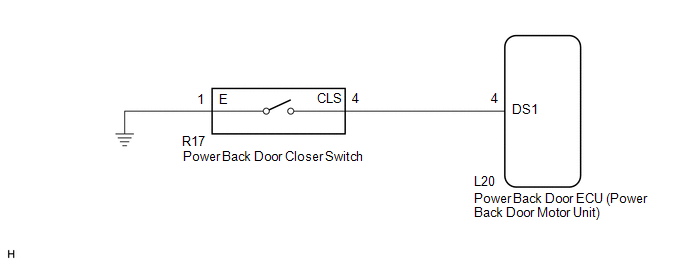

WIRING DIAGRAM

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (POWER BACK DOOR CLOSER SWITCH) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Back Door / Data List.

(e) Check the Data List to determine if the power back door closer switch functions properly.

Back Door (Power Back Door ECU)|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

PBD Close SW |

Power back door closer switch signal / ON or OFF |

ON: Power back door closer switch on OFF: Power back door closer switch off |

- |

OK:

The power back door closer switch functions as specified in the normal condition column.

| OK | .gif) |

REPLACE POWER BACK DOOR ECU (POWER BACK DOOR MOTOR UNIT) |

|

|

2. |

INSPECT POWER BACK DOOR CLOSER SWITCH |

|

(a) Remove the power back door closer switch (See page

|

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

4 - 1 |

Pushed (on) |

Below 1 Ω |

|

4 - 1 |

Free (off) |

10 kΩ or higher |

|

*1 |

Component without harness connected (Power Back Door Closer Switch) |

| NG | .gif) |

REPLACE POWER BACK DOOR CLOSER SWITCH |

|

|

3. |

CHECK HARNESS AND CONNECTOR (POWER BACK DOOR CLOSER SWITCH - POWER BACK DOOR ECU) |

(a) Disconnect the R17 power back door closer switch and L20 power back door ECU connectors.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R17-4 (CLS) - L20-4 (DS1) |

Always |

Below 1 Ω |

|

R17-1 (E) - Body ground |

Always |

Below 1 Ω |

|

R17-4 (CLS) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE POWER BACK DOOR ECU (POWER BACK DOOR MOTOR UNIT) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Power Back Door cannot be Operated Using Any Switch

Power Back Door cannot be Operated Using Any Switch

DESCRIPTION

When the power back door cannot be operated using any switch, one of the following

may be the cause: 1) initialization of the power back door ECU (power back door

motor unit), 2) powe ...

Jam Protection Function Activates During Power Back Door Operation

Jam Protection Function Activates During Power Back Door Operation

DESCRIPTION

When the jam protection function activates during power back door operation,

one of the following may be the cause: 1) improper fit of back door, or a foreign

object is stuck in the b ...

Other materials about Toyota Venza:

Initialization has not been Performed (B2450)

DESCRIPTION

The headlight leveling ECU assembly stores this DTC if initialization has not

been performed after the ECU was replaced.

DTC No.

DTC Detecting Condition

Trouble Area

B2450

Initializat ...

Lost Communication with Power Source Control (B278C)

DESCRIPTION

This DTC is stored when LIN communication between the certification ECU (smart

key ECU assembly) and power management control ECU stops for more than 10 seconds.

DTC Code

DTC Detection Condition

Trouble Area

...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

0.1275

.gif)

.gif) ).

)..png)