Toyota Venza: Motor Circuit Malfunction (C1522-C1555)

DESCRIPTION

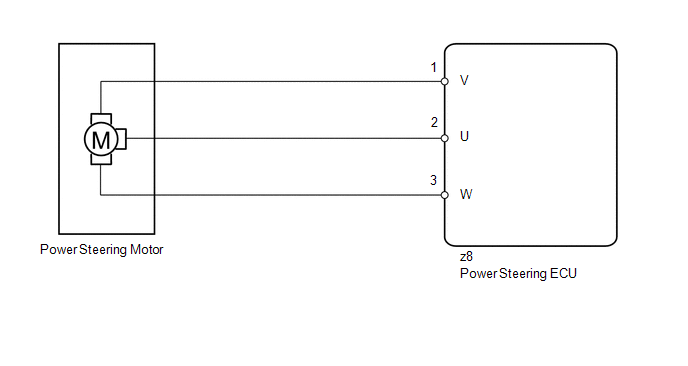

The power steering ECU supplies current to the power steering motor through the motor circuit.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

C1522 |

Motor current sensor malfunction |

|

|

C1523 |

Excessively large current deviation |

|

|

C1524 |

Short (or open) in motor circuit or abnormal voltage or current in motor circuit |

|

|

C1555 |

Motor relay failure |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the power steering ECU and steering column assembly have been replaced, perform

the rotation angle sensor initialization and torque sensor zero point calibration

(See page .gif) ).

).

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (MOTOR VOLTAGE) |

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / EMPS / Data List.

(f) Select the items "Motor Terminal Volt(U)", "Motor Terminal Volt(V)" and "Motor Terminal Volt(W)" in the Data List and read the value displayed on the Techstream.

EMPS|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Motor Terminal Volt(U) |

Motor terminal voltage (U phase)/ Min.: 0 V Max.: 46.667 V |

During steering operation, value changes within 4 to 46 V range |

The engine is running and steering wheel is being turned. |

|

Motor Terminal Volt(V) |

Motor terminal voltage (V phase)/ Min.: 0 V Max.: 46.667 V |

During steering operation, value changes within 4 to 46 V range |

The engine is running and steering wheel is being turned. |

|

Motor Terminal Volt(W) |

Motor terminal voltage (W phase)/ Min.: 0 V Max.: 46.667 V |

During steering operation, value changes within 4 to 46 V range |

The engine is running and steering wheel is being turned. |

|

Result |

Proceed to |

|---|---|

|

During steering operation, value changes within 4 to 46 V range |

A |

|

During steering operation, voltage is not generated |

B |

| A | .gif) |

REPLACE POWER STEERING ECU |

| B | .gif) |

REPLACE STEERING COLUMN ASSEMBLY |

Vehicle Speed Signal Malfunction (C1541)

Vehicle Speed Signal Malfunction (C1541)

DESCRIPTION

The power steering ECU receives vehicle speed signals from the brake actuator

assembly (skid control ECU) via CAN communication. The ECU provides appropriate

assisting force in accord ...

Torque Sensor Zero Point Adjustment Incomplete (C1516,C1526)

Torque Sensor Zero Point Adjustment Incomplete (C1516,C1526)

DESCRIPTION

These DTCs do not indicate a malfunction. The power steering ECU stores these

DTCs when it determines that the rotation angle sensor value initialization and

torque sensor zero point ...

Other materials about Toyota Venza:

Precaution

PRECAUTION

1. PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following system after the terminal is reconnected:

System Name

...

Satellite Radio Broadcast cannot be Selected or After Selecting Broadcast, Broadcast

cannot be Added into Memory

CAUTION / NOTICE / HINT

NOTICE:

Some satellite radio broadcasts require payment. A contract must be made between

a satellite radio company and the user. If the contract expires, it will not be

possible to listen to the broadcast.

PROCEDURE

1 ...

Disposal

DISPOSAL

CAUTION / NOTICE / HINT

HINT:

The tire pressure warning valve and transmitter is powered by a lithium battery.

When disposing of the tire pressure warning valve and transmitter, remove the battery

and dispose of it correctly.

PROCEDURE

1. DIS ...

0.1496