Toyota Venza: LVL Terminal Circuit

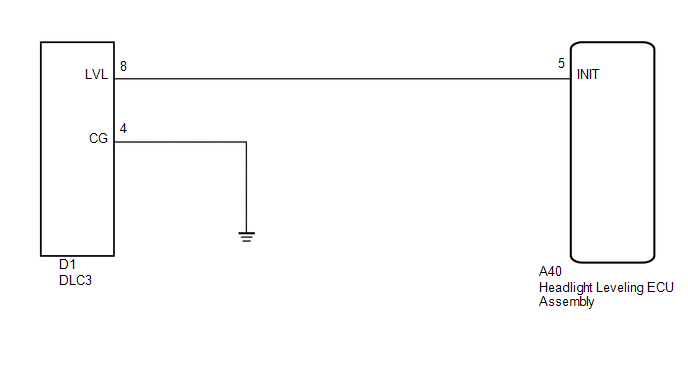

DESCRIPTION

- By connecting terminals LVL and CG of the DLC3, the headlight leveling ECU assembly initializes the height control sensor signal.

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (DLC3 - HEADLIGHT LEVELING ECU ASSEMBLY) |

|

(a) Disconnect the A40 headlight leveling ECU assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

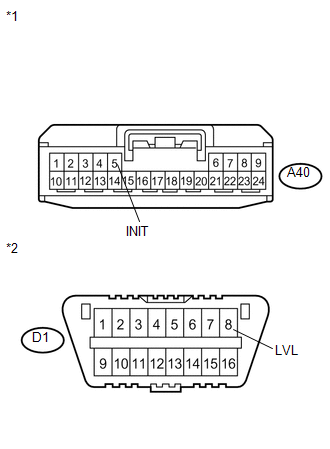

A40-5 (INIT) - D1-8 (LVL) |

Always |

Below 1 Ω |

|

A40-5 (INIT) - Body ground |

Always |

10 kΩ or higher |

|

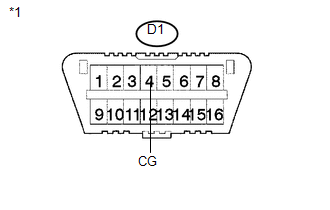

*1 |

Front view of wire harness connector (to Headlight Leveling ECU Assembly) |

|

*2 |

DLC3 |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

CHECK HARNESS AND CONNECTOR (DLC3 - BODY GROUND) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Inner Rear View Mirror Power Source Circuit

Inner Rear View Mirror Power Source Circuit

DESCRIPTION

This circuit detects the state of the ignition switch, and sends it to the inner

rear view mirror assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for ci ...

Diagnosis Circuit

Diagnosis Circuit

DESCRIPTION

The headlight leveling ECU assembly outputs DTC information to the Techstream

via this circuit.

WIRING DIAGRAM

PROCEDURE

1.

CHECK HARNESS AND CONNECTOR (DLC3 ...

Other materials about Toyota Venza:

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

The wireless door lock control system troubleshooting procedures are

based on the premise that the power door lock control system is operating

normally. Check the power door lock control system first before troub ...

Window Glass Antenna Wire

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT WINDOW GLASS ANTENNA WIRE

(a) Check for continuity of the antenna.

HINT:

Check for continuity at the center of each antenna wire as shown in the

illustration.

N ...

Camshaft Position "B" Actuator Circuit / Open (Bank 1) (P0013)

DESCRIPTION

The Variable Valve Timing (VVT) system adjusts the exhaust valve timing to improve

driveability. The engine oil pressure turns the VVT controller to adjust the valve

timing.

The camshaft timing oil control valve is a solenoid valve and switch ...

0.1352

.gif)