Toyota Venza: Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

If installing a new rear differential carrier assembly, remove the 2 differential side seal caps before installing the rear drive shaft assembly.

PROCEDURE

1. INSTALL REAR DIFFERENTIAL DYNAMIC DAMPER

HINT:

This step should be performed only when the rear differential dynamic damper is replaced.

|

(a) Install the rear differential dynamic damper with the bolt. Torque: 27 N·m {270 kgf·cm, 20 ft·lbf} |

|

2. TEMPORARILY TIGHTEN REAR NO. 1 DIFFERENTIAL SUPPORT

|

(a) Temporarily install the rear No. 1 differential support to the differential carrier assembly with 2 new bolts and 2 new nuts. NOTICE:

HINT: The nuts have tabs to prevent them from rotating. |

|

3. INSTALL DIFFERENTIAL SUPPORT

|

(a) Install the differential support to the differential carrier assembly with 3 new bolts. Torque: 167 N·m {1700 kgf·cm, 123 ft·lbf} |

|

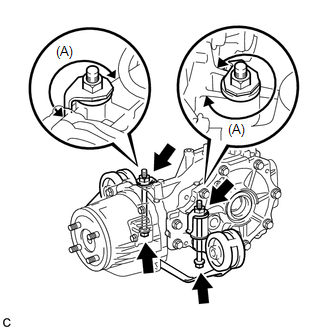

4. TEMPORARILY TIGHTEN REAR DIFFERENTIAL CARRIER ASSEMBLY WITH DIFFERENTIAL SUPPORT

|

(a) Temporarily install the rear differential carrier assembly with differential support to the rear side of the rear suspension member assembly with the 3 rear mounting bolts. |

|

|

(b) Temporarily install the rear differential carrier assembly with differential support to the front side of the rear suspension member assembly with the 2 bolts and 2 nuts. HINT: The nuts have tabs to prevent them from rotating. |

|

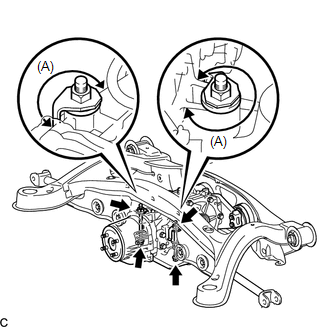

5. FULLY TIGHTEN REAR DIFFERENTIAL CARRIER ASSEMBLY WITH DIFFERENTIAL SUPPORT

NOTICE:

Do not tighten the bolts with the inner cylinder or rear differential mount cushion tilted.

|

(a) Install the rear differential carrier assembly with differential support to the rear side of the rear suspension member assembly with the 3 rear mounting bolts. Torque: 95 N·m {970 kgf·cm, 70 ft·lbf} |

|

|

(b) Install the rear differential carrier assembly with differential support to the front side of the rear suspension member assembly with the 2 bolts and 2 nuts. Torque: 114 N·m {1162 kgf·cm, 84 ft·lbf} HINT: The nuts have tabs to prevent them from rotating. |

|

6. FULLY TIGHTEN REAR NO. 1 DIFFERENTIAL SUPPORT

|

(a) Install the rear No. 1 differential support to the rear differential carrier assembly with the 2 new bolts and 2 new nuts. Torque: 86 N·m {877 kgf·cm, 63 ft·lbf} NOTICE: Make sure that each nut is installed to position (A) shown in the illustration. HINT: The nuts have tabs to prevent them from rotating. |

|

7. INSTALL REAR SUSPENSION MEMBER

.gif)

8. INSTALL FRAME WIRE

.gif)

9. INSTALL NO. 3 FLOOR WIRE (w/ HID Headlight System)

.gif)

10. INSTALL REAR DRIVE SHAFT SNAP RING LH

.gif)

11. INSTALL REAR DRIVE SHAFT ASSEMBLY LH

.gif)

12. INSTALL REAR DRIVE SHAFT SNAP RING RH

.gif)

13. INSTALL REAR DRIVE SHAFT ASSEMBLY RH

.gif)

14. CONNECT REAR NO. 1 SUSPENSION ARM ASSEMBLY LH

.gif)

15. CONNECT REAR NO. 1 SUSPENSION ARM ASSEMBLY RH

.gif)

16. TEMPORARILY TIGHTEN REAR NO. 2 SUSPENSION ARM ASSEMBLY LH

.gif)

17. TEMPORARILY TIGHTEN REAR NO. 2 SUSPENSION ARM ASSEMBLY RH

.gif)

18. INSTALL REAR STRUT ROD ASSEMBLY LH

.gif)

19. INSTALL REAR STRUT ROD ASSEMBLY RH

.gif)

20. INSTALL REAR HEIGHT CONTROL SENSOR SUB-ASSEMBLY (w/ HID Headlight System)

.gif)

21. INSTALL NO. 3 PARKING BRAKE CABLE ASSEMBLY

.gif)

22. INSTALL NO. 2 PARKING BRAKE CABLE ASSEMBLY

.gif)

23. INSTALL REAR AXLE SHAFT NUT LH

.gif)

24. INSTALL REAR AXLE SHAFT NUT RH

.gif)

25. INSTALL REAR SPEED SENSOR LH

.gif)

26. INSTALL REAR SPEED SENSOR RH

.gif)

27. TEMPORARILY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

.gif)

28. FULLY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

.gif)

29. INSTALL NO. 1 FLOOR UNDER COVER

.gif)

30. INSPECT AND ADJUST TRANSFER OIL

(a) Inspect and adjust transfer oil (See page

.gif) ).

).

31. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Install the center exhaust pipe assembly.

HINT:

Refer to the instructions for Installation of the exhaust pipe (See page

.gif) for 2GR-FE,

for 2GR-FE, .gif)

for 1AR-FE).

32. ADD DIFFERENTIAL OIL

(a) When reusing the rear differential carrier assembly:

|

(1) Using a 10 mm hexagon wrench, install a new gasket and the rear differential drain plug. Torque: 39 N·m {398 kgf·cm, 29 ft·lbf} |

|

(2) Add differential oil (See page .gif) ).

).

(b) When using a new rear differential carrier assembly:

|

(1) Using a 10 mm hexagon wrench, remove the rear differential carrier cover plug and gasket. |

|

(2) Add differential oil (See page .gif) ).

).

33. INSPECT DIFFERENTIAL OIL

.gif)

34. INSTALL REAR DIFFERENTIAL CARRIER COVER PLUG

.gif)

35. INSPECT FOR DIFFERENTIAL OIL LEAK

36. INSPECT FOR EXHAUST GAS LEAK

37. INSTALL REAR WHEELS

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

38. STABILIZE SUSPENSION

.gif)

39. FULLY TIGHTEN REAR NO. 2 SUSPENSION ARM ASSEMBLY LH

.gif)

40. FULLY TIGHTEN REAR NO. 2 SUSPENSION ARM ASSEMBLY RH

.gif)

41. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

(a) Inspect and adjust the rear wheel alignment (See page

.gif) ).

).

42. CHECK FOR SPEED SENSOR SIGNAL

(a) Check for the speed sensor signal (See page

.gif) ).

).

43. HEIGHT CONTROL SENSOR SIGNAL INITIALIZATION (w/ HID Headlight System)

(a) Initialize the height control sensor signal (See page

.gif) ).

).

44. INSPECT AND ADJUST HEADLIGHT AIMING (w/ HID Headlight System)

(a) Inspect and adjust the headlight aiming (See page

.gif) ).

).

Reassembly

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use an overhaul stand as necessary.

PROCEDURE

1. INSTALL DIFFERENTIAL RING GEAR

(a) Clean the contact surfaces of the rear differential case sub-assembly ...

Other materials about Toyota Venza:

Glossary Of Sae And Toyota Terms

GLOSSARY OF SAE AND TOYOTA TERMS

This glossary lists all SAE-J1930 terms and abbreviations used in this manual

in compliance with SAE recommendations, as well as their TOYOTA equivalents.

SAE

Abbreviation

SAE Term

TOYOTA ...

How To Use This Manual

General Information

GENERAL INFORMATION

1. GENERAL DESCRIPTION

(a) This manual is written in accordance with SAE J2008.

(b) Repair operations can be separated mainly into the following 3 processes:

(1) Diagnosis

(2) Removing / Installing, Replacing, Di ...

Back Camera Disconnected (C1622)

DESCRIPTION

This DTC is stored if the navigation receiver assembly*1 or radio and display

receiver assembly*2 judges that the signals or signal lines between the navigation

receiver assembly*1 or radio and display receiver assembly*2, and the rear televis ...

0.1563

.png)

.png)

.png)

.png)

.png)

.png)