Toyota Venza: Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the LH side and RH side.

- The following procedure is for the LH side.

- If the sensor rotor needs to be replaced, replace it together with the front drive shaft assembly.

PROCEDURE

1. INSTALL FRONT SPEED SENSOR

|

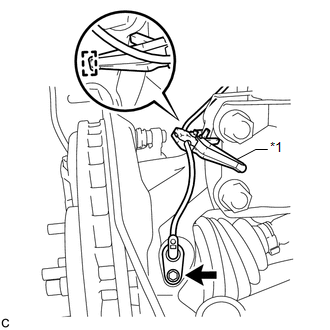

(a) Install the resin clamp and front speed sensor with the bolt. Torque: 8.5 N·m {87 kgf·cm, 75 in·lbf} NOTICE:

|

|

|

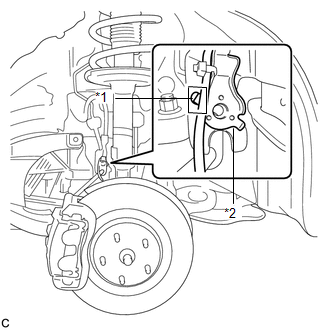

(b) Temporarily install the No. 1 sensor clamp. NOTICE: Be sure to insert the No. 1 sensor clamp claw into the stopper hole while installing the No. 1 sensor clamp. Text in Illustration

|

|

|

(c) Install the front brake flexible hose and No. 1 sensor clamp together to the shock absorber with the bolt. Torque: 19 N·m {194 kgf·cm, 14 ft·lbf} NOTICE:

|

|

|

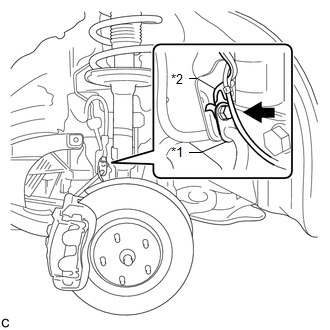

(d) Install the No. 2 sensor clamp to the body with the bolt. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} Text in Illustration

|

|

|

(e) Install the 2 clamps and connect the front speed sensor connector. |

|

2. INSTALL FRONT FENDER LINER LH

.gif)

3. INSTALL FRONT FENDER OUTSIDE MOULDING LH

.gif)

4. INSTALL FRONT WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

6. CHECK FOR SPEED SENSOR SIGNAL

HINT:

(See page .gif) )

)

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure is for the LH side.

If the sensor rotor needs to be replaced, repla ...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. REMOVE RADIATOR ASSEMBLY AND FAN ASSEMBLY WITH MOTOR

HINT:

See page

2. REMOVE FAN

(a) Remove the nut and fan.

3. REMOVE NO. 2 FAN

(a) Remove the nut and No. 2 f ...

System Description

SYSTEM DESCRIPTION

1. OUTLINE OF THEFT DETERRENT SYSTEM

The theft deterrent system can be set by locking the doors using the

transmitter or key, or by opening and closing the doors (for details, refer

to Active Arming Mode or Passive Arming Mo ...

Sending Malfunction (Navigation to APGS) (U0073,U0100,U0140,U0155)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the CAN communication circuit.

DTC No.

DTC Detection Condition

Trouble Area

U0073

CAN bus connection error

CAN communicatio ...

0.1151

.png)

.png)