Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN COMPRESSOR AND MAGNETIC CLUTCH

|

(a) Temporarily install the compressor and magnetic clutch and bracket with the 4 bolts. |

|

2. INSTALL COMPRESSOR AND MAGNETIC CLUTCH

|

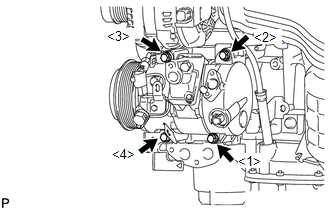

(a) Install the compressor and magnetic clutch and bracket with the 4 bolts. Torque: 25 N·m {255 kgf·cm, 18 ft·lbf} NOTICE: Tighten the bolts in the order shown in the illustration to install the compressor and magnetic clutch. |

|

|

(b) Engage each clamp. |

|

(c) Connect each connector.

3. CONNECT SUCTION HOSE SUB-ASSEMBLY

(a) Remove the attached vinyl tape from the hose.

(b) Apply sufficient compressor oil to a new O-ring and the fitting surface of the compressor and magnetic clutch.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring onto the suction hose sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surfaces free from dirt or any foreign objects.

|

(d) Install the suction hose sub-assembly onto the compressor and magnetic clutch with the bolt. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} |

|

4. CONNECT COOLER REFRIGERANT DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Apply sufficient compressor oil to a new O-ring and the fitting surface of the compressor and magnetic clutch.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring onto the discharge hose.

NOTICE:

Keep the O-ring and O-ring fitting surfaces free from dirt or any foreign objects.

|

(d) Install the cooler refrigerant discharge hose onto the compressor and magnetic clutch with the bolt. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} |

|

5. INSTALL RADIATOR ASSEMBLY AND FAN ASSEMBLY WITH MOTOR

.gif)

6. INSTALL COOLER CONDENSER ASSEMBLY

.gif)

7. CONNECT AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY

.gif)

8. CONNECT COOLER REFRIGERANT DISCHARGE HOSE

.gif)

9. INSTALL UPPER RADIATOR SUPPORT

.gif)

10. CONNECT OUTLET OIL COOLER HOSE

.gif)

11. CONNECT INLET OIL COOLER HOSE

.gif)

12. INSTALL NO. 2 RADIATOR HOSE

.gif)

13. CONNECT NO. 1 RADIATOR HOSE

.gif)

14. CONNECT OUTLET RESERVE TANK HOSE

.gif)

15. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY

.gif)

16. INSTALL HOOD LOCK ASSEMBLY (w/o Engine Hood Courtesy Switch)

.gif)

17. INSTALL HOOD LOCK ASSEMBLY (w/ Engine Hood Courtesy Switch)

.gif)

18. INSTALL LOW PITCHED HORN ASSEMBLY

.gif)

19. INSTALL HIGH PITCHED HORN ASSEMBLY

.gif)

20. INSTALL INLET NO. 1 AIR CLEANER

.gif)

21. INSTALL BATTERY

.gif)

22. INSTALL AIR CLEANER CASE

.gif)

23. INSTALL AIR CLEANER CAP WITH HOSE

.gif)

24. INSTALL INLET NO. 2 AIR CLEANER

.gif)

25. INSTALL RADIATOR GRILLE

.gif)

26. INSTALL V-RIBBED BELT

.gif)

27. INSTALL FRONT FENDER APRON RH

28. INSTALL FRONT FENDER LINER RH

29. INSTALL FRONT WHEEL RH

.gif)

30. ADD ENGINE COOLANT

.gif)

31. ADD AUTOMATIC TRANSAXLE FLUID

for U660F: (See page .gif) )

)

for U660E: (See page .gif) )

)

32. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

33. CHARGE WITH REFRIGERANT

.gif)

34. WARM UP ENGINE

.gif)

35. INSPECT FOR REFRIGERANT LEAK

.gif)

36. INSPECT FOR COOLANT LEAK

.gif)

37. INSTALL V-BANK COVER SUB-ASSEMBLY

.gif)

38. INSTALL COOL AIR INTAKE DUCT SEAL

.gif)

39. INSTALL NO. 2 ENGINE UNDER COVER

40. INSTALL NO. 1 ENGINE UNDER COVER

41. INSPECT HOOD SUB-ASSEMBLY

.gif)

42. ADJUST HOOD SUB-ASSEMBLY

.gif)

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT COMPRESSOR AND MAGNETIC CLUTCH (A/C LOCK SENSOR)

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL MAGNETIC CLUTCH ASSEMBLY

(a) Install the magnetic clutch stator while aligning the protrusion

on the stator with the notch on the air compressor assem ...

Other materials about Toyota Venza:

VSC OFF Indicator Light does not Come ON

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN communication.

WIRING DIAGRAM

Refer to VSC OFF Indicator Light Remains ON (See page

).

PROCEDURE

1.

CHECK CAN COMMUNICATION SYSTEM

(a) Check ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL THERMOSTAT

(a) Install a new gasket to the thermostat.

(b) Install the thermostat with the jiggle valve facing upward.

HINT:

The jiggle valve may be set to within 10° on either side of the prescribed

...

Lost Communication with Rear Airbag Sensor LH (B1637/82,B1638/82,B1647/82,B1697/82,B1698/82)

DESCRIPTION

The side collision sensor LH circuit (to determine deployment of the front seat

side airbag assembly LH and curtain shield airbag assembly LH) is composed of the

center airbag sensor assembly, rear airbag sensor LH and side airbag sensor LH.

...

0.1278

.png)

.png)

.png)

.png)