Toyota Venza: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL MAGNETIC CLUTCH ASSEMBLY

|

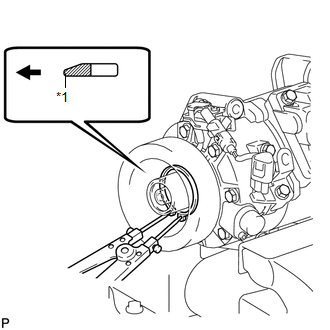

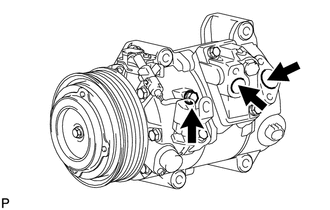

(a) Install the magnetic clutch stator while aligning the protrusion on the stator with the notch on the air compressor assembly as shown in the illustration. |

|

|

(b) Engage the clamp. |

|

(c) Install the bracket with the screw.

(d) Connect the connector.

|

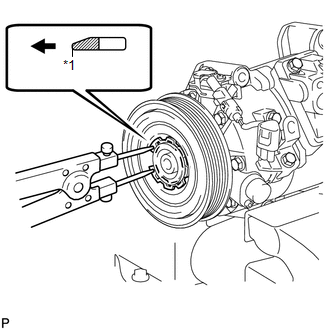

(e) Using a snap ring expander, install a new snap ring with the chamfered side facing up. Text in Illustration

NOTICE: Take care not to damage the seal cover of the bearing when installing the snap ring. |

|

|

(f) Using a snap ring expander, install the magnetic clutch rotor and a new snap ring with the chamfered side facing up. Text in Illustration

NOTICE:

|

|

(g) Install the magnetic clutch washers and magnetic clutch hub.

NOTICE:

Do not change the combination of the magnetic clutch washers used before disassembly.

|

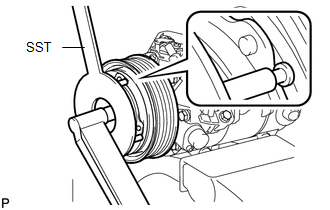

(h) Using SST, hold the magnetic clutch hub and install the bolt. SST: 09985-00270 Torque: 18 N·m {184 kgf·cm, 13 ft·lbf} NOTICE: Make sure that there is no foreign matter or oil on the compressor shaft, bolt and clutch hub. |

|

2. INSPECT MAGNETIC CLUTCH CLEARANCE

|

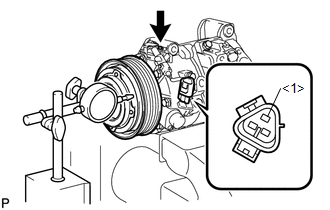

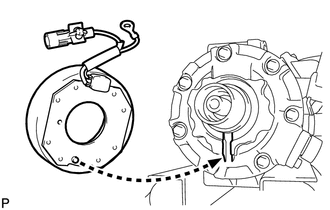

(a) Set the dial indicator to the magnetic clutch hub. |

|

(b) Connect a positive (+) lead from the battery to terminal 1 of the magnetic clutch connector, and a negative (-) lead to the ground wire. Turn the magnetic clutch on and off and measure the clearance.

Standard clearance:

0.26 to 0.60 mm (0.0103 to 0.0236 in.)

If the measured value is not within the standard range, remove the magnetic clutch hub and adjust it with magnetic clutch washers.

NOTICE:

Adjustment should be performed with 3 or less magnetic clutch washers.

(c) Remove the compressor and magnetic clutch from the vise.

3. ADJUST COMPRESSOR OIL LEVEL

|

(a) When replacing the compressor and magnetic clutch with a new one, gradually discharge the refrigerant from the service valve, and drain the following amount of oil from the new compressor and magnetic clutch before installation. Standard: (Oil capacity inside the new compressor and magnetic clutch: 130 + 15 cc (4.4 + 0.51 fl.oz.) ) - (Remaining oil amount in the removed compressor and magnetic clutch) = (Oil amount to be removed from the new compressor when replacing) NOTICE:

|

|

Installation

Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN COMPRESSOR AND MAGNETIC CLUTCH

(a) Temporarily install the compressor and magnetic clutch and bracket

with the 4 bolts.

...

Condenser

Condenser

...

Other materials about Toyota Venza:

HL AutoLeveling ECU Failure (B2420)

DESCRIPTION

When the headlight leveling ECU assembly detects a malfunction in itself, this

DTC is stored.

DTC No.

DTC Detecting Condition

Trouble Area

B2420

Malfunction of headlight leveling ECU ...

Illumination for Panel Switch does not Come on with Tail Switch ON

PROCEDURE

1.

CHECK VEHICLE SIGNAL (OPERATION CHECK)

(a) Enter the "Vehicle Signal Check Mode" screen.

Refer to Check Vehicle Signal in Operation Check (See page

).

...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL SHIFT SOLENOID VALVE SL4

(a) Coat the shift solenoid valve SL4 and bolt with ATF.

Text in Illustration

*1

Lock Plate

*2

Solenoid V ...

0.1545

.png)