Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE MOUNTING DAMPER

|

(a) Install the engine mounting damper with the 3 bolts. Torque: 9.0 N·m {92 kgf·cm, 80 in·lbf} |

|

2. INSTALL WIRING HARNESS CLAMP BRACKET

|

(a) Install the bracket with the bolt. Torque: 8.4 N·m {86 kgf·cm, 74 in·lbf} |

|

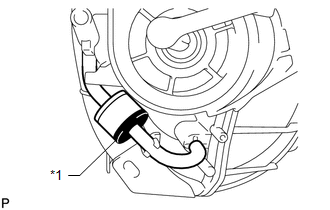

3. INSTALL CHECK VALVE

|

(a) Connect the 2 vacuum hoses to the intake manifold to install the check valve. |

|

|

(b) Check that the check valve is installed as shown in the illustration. Text in Illustration

|

|

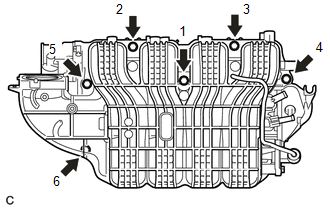

4. INSTALL INTAKE MANIFOLD

|

(a) Close the tumble control valves. NOTICE: The tumble control valves may be damaged if they are not closed before installing the intake manifold. HINT: Connect the battery to the terminals of the actuator to operate the motor

and close the valves (See page |

|

|

(b) Install a new gasket to the intake manifold. |

|

|

(c) Install the intake manifold by tightening the 6 bolts in the sequence shown in the illustration. Torque: 28 N·m {286 kgf·cm, 21 ft·lbf} |

|

|

(d) Connect the intake air control actuator connector. |

|

(e) Attach the 2 clamps to the intake manifold and bracket.

(f) Install the wire harness with the bolt.

Torque:

8.4 N·m {86 kgf·cm, 74 in·lbf}

|

(g) Install the wire harness bracket with the bolt. Torque: 8.4 N·m {86 kgf·cm, 74 in·lbf} |

|

(h) Connect the fuel vapor feed hose, clamp and connector.

|

(i) Install the 2 wire harness brackets with the 2 bolts. Torque: 8.4 N·m {86 kgf·cm, 74 in·lbf} |

|

5. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

.gif)

6. INSTALL UNION TO CONNECTOR TUBE HOSE

|

(a) Install the union to connector tube hose to the intake manifold. |

|

7. CONNECT NO. 2 VENTILATION HOSE

|

(a) Connect the No. 2 ventilation hose to the intake manifold. |

|

8. INSTALL VACUUM SWITCHING VALVE ASSEMBLY (for ACIS)

|

(a) Install the vacuum switching valve (for ACIS) with the bolt. Torque: 9.0 N·m {92 kgf·cm, 80 in·lbf} |

|

(b) Connect the 2 vacuum hoses, 2 union to connector tube hoses, clamp and connector.

9. INSTALL THROTTLE BODY ASSEMBLY

(a) Install the throttle body assembly (See page

.gif) ).

).

10. CONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

11. INSPECT FOR FUEL LEAK

HINT:

(See page .gif) ).

).

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT INTAKE AIR CONTROL VALVE (for ACIS)

(a) Inspect the diaphragm.

(1) Using a vacuum pump, apply a vacuum of 60 kPa (450 mmHg, 17.7 in.Hg)

or higher to ...

Intake System

Intake System

Parts Location

PARTS LOCATION

ILLUSTRATION

System Diagram

SYSTEM DIAGRAM

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT INTAKE SYSTEM

HINT:

Perform "Inspec ...

Other materials about Toyota Venza:

Power Back Door cannot be Closed Using the Power Back Door Closer Switch

DESCRIPTION

When the power back door cannot be closed using the power back door closer switch,

either of the following may be malfunctioning: 1) power back door closer switch

circuit or 2) power back door ECU (power back door motor unit).

WIRING DIAGRAM

...

Installing child restraints

Follow the child restraint system manufacturer’s instructions. Firmly secure

child restraints to the rear seats using the LATCH anchors or a seat belt. Attach

the top tether strap when installing a child restraint.

The lap/shoulder belt can be used if y ...

Back Door Entry Unlock Function does not Operate

DESCRIPTION

If the entry back door open function does not operate but the back door entry

lock function operates, the communication between the vehicle and key is normal.

As a faulty part, the back door open switch circuit (from the back door opener switc ...

0.1286

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)