Toyota Venza: Intake System

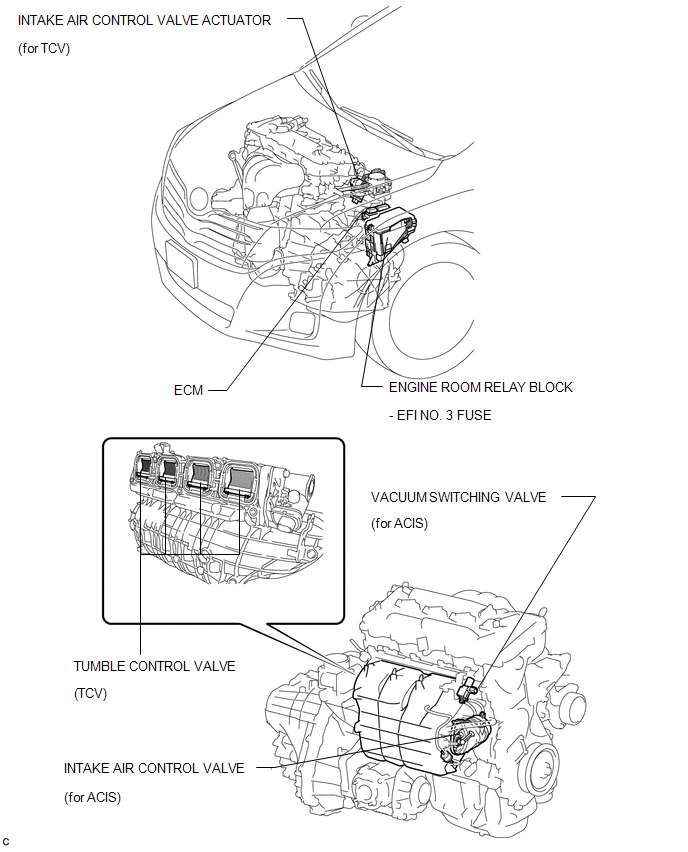

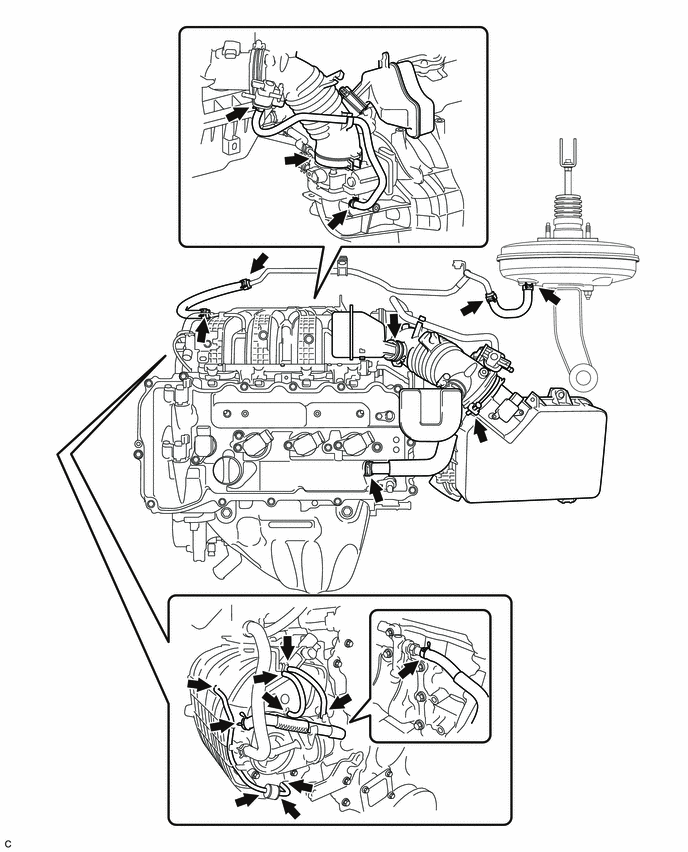

Parts Location

PARTS LOCATION

ILLUSTRATION

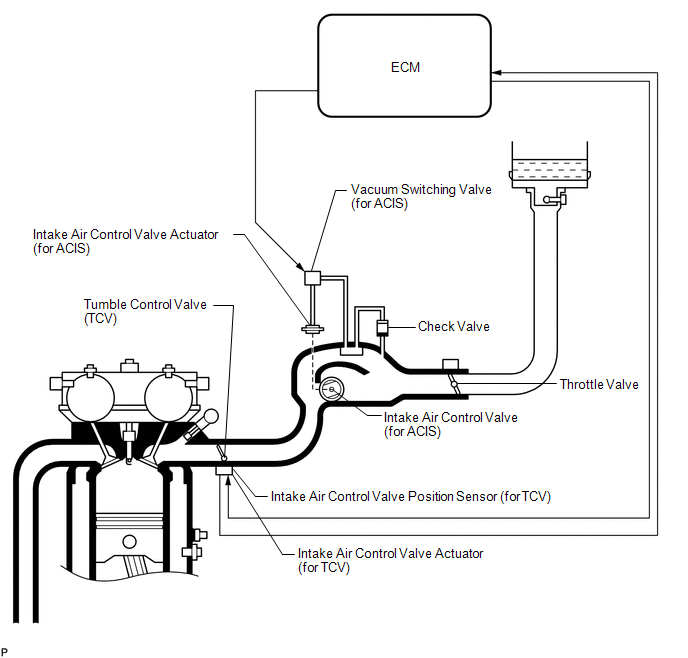

System Diagram

SYSTEM DIAGRAM

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT INTAKE SYSTEM

HINT:

Perform "Inspection After Repair" after repairing vacuum leaks in the intake

system (See page .gif) ).

).

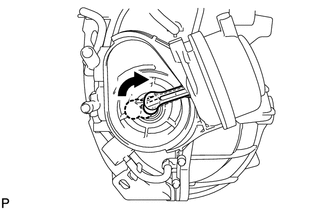

(a) Check that there are no vacuum leaks at the points shown in the illustration.

2. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after repairing vacuum leaks in the intake

system (See page .gif) ).

).

3. INSPECT INTAKE AIR CONTROL VALVE (for ACIS)

(a) Connect the Techstream to the DLC3.

(b) Start the engine and turn the Techstream on.

(c) Warm up the engine.

|

(d) Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VSV for Intake Control. |

|

(e) When "Activate the VSV for Intake Control" is turned on, check that the actuator rod operates.

If the operation is not as specified, inspect the intake air control valve, vacuum

tank and check valve (See page .gif) ).

).

(f) When "Activate the VSV for Intake Control" is turned off, check that the actuator rod returns to its original position.

If the operation is not as specified, inspect the intake air control valve and

vacuum hose (See page .gif) ).

).

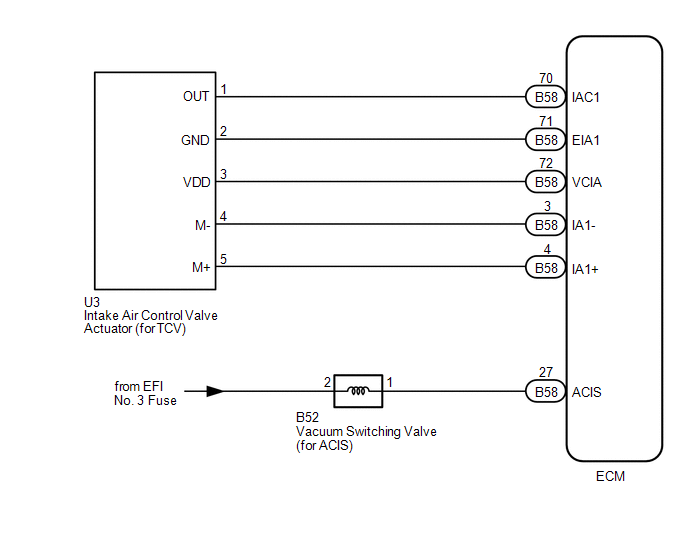

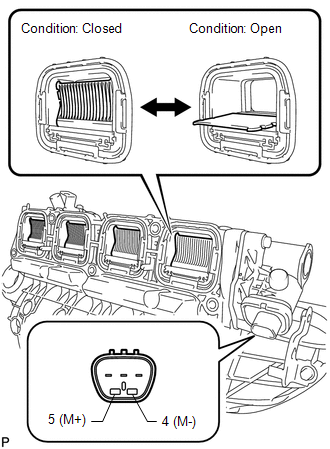

4. INSPECT INTAKE AIR CONTROL VALVE ACTUATOR (for TCV)

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON (do not run the engine).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Active Test / All Data / Control the IAC Duty Ratio.

(1) Set the duty ratio to 60% or -60% for 1 to 3 seconds, and then return the duty ratio to 0%. Check Intake Air Control Position in the Data List.

Specified Condition:

|

Condition (Active Test) |

Specified Condition (Data List) |

|---|---|

|

Control the IAC Duty Ratio set to 60% |

Intake Air Control Position 35° or more |

|

Control the IAC Duty Ratio set to -60% |

Intake Air Control Position 17° or less |

NOTICE:

- Supply power to the intake control valve for 1 to 3 seconds.

- If power is supplied to the intake control valve for less than 1 second, the gear of the tumble control valve does not reach the stopper and the value in the Data List may be incorrect.

- If power is supplied to the intake control valve for more than 3 seconds, the motor may be damaged.

- Do not perform this inspection more than 2 times consecutively.

HINT:

The standard duty ratio for inspections is 60% or -60%. However, if the value in the Data List is not as specified, set the duty ratio to 100% or -100% for 1 to 3 seconds, and check the value in the Data List again.

(e) When the result is not as specified during the Active Test, perform the following procedure.

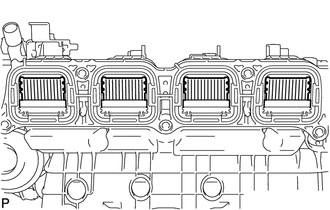

(1) Remove the intake manifold (See page .gif) ).

).

HINT:

When removing the intake manifold, the tumble control valves are half open.

(2) Check that the valves move when connecting the battery to the terminals of the intake air control valve actuator.

Standard:

|

Tester Connection |

Specified Condition |

|---|---|

|

Positive (+) battery voltage applied to terminal 4 (M-), and negative (-) battery voltage applied to terminal 5 (M+) |

Open → Closed |

|

Positive (+) battery voltage applied to terminal 5 (M+), and negative (-) battery voltage applied to terminal 4 (M-) |

Closed → Open |

NOTICE:

- Apply battery voltage for 1 to 3 seconds.

- If battery voltage is applied for more than 3 seconds, the actuator may be damaged.

- Do not allow the lead wires to contact the other terminals.

(3) When the results are not as specified, perform the following inspections.

Check that the valves are not cracked or deformed.

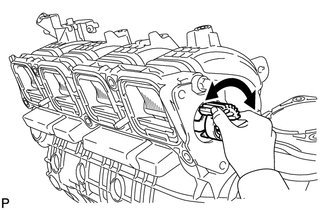

Remove the intake air control actuator, and check that the valves move smoothly.

If there are no problems with the valves, inspect the intake air control valve

actuator (See page .gif) ).

).

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE MOUNTING DAMPER

(a) Install the engine mounting damper with the 3 bolts.

Torque:

9.0 N·m {92 kgf·cm, 80 in·lbf}

...

Other materials about Toyota Venza:

XM Tuner Antenna Disconnected (B15FE,B15FF)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the roof antenna assembly

which is connected to the stereo component tuner assembly.

DTC No.

DTC Detection Condition

Trouble Area

B15FE

...

Fail-safe Chart

FAIL-SAFE CHART

1. Fail-safe

This function minimizes the loss of operation when any abnormality occurs in

a sensor or solenoid.

Fail-safe Control List

Malfunction Part

Function

Input Turbine Speed Sensor

...

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

When disconnecting the steering intermediate shaft assembly and pinion shaft

of steering gear assembly, be sure to place matchmarks before servicing.

PROCEDURE

1. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

2. SECUR ...

0.1726