Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL HEATED OXYGEN SENSOR

.gif)

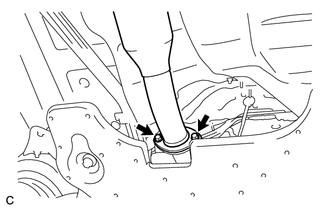

2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

|

(a) Using a vernier caliper, measure the free length of the compression springs. Minimum Free Length: 41.5 mm (1.63 in.) If the free length is less than the minimum, replace the compression spring. |

|

(b) Temporarily install a new gasket to the exhaust manifold converter sub-assembly.

|

(c) Using a plastic hammer and wooden block, tap in the gasket until its surface is flush with the exhaust manifold converter sub-assembly. Text in Illustration

NOTICE:

|

|

|

(d) Install the front exhaust pipe assembly to the exhaust manifold converter sub-assembly with the 2 bolts and 2 compression springs. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

(e) Connect the heated oxygen sensor connector.

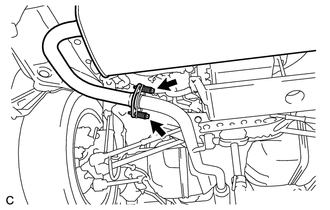

3. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the center exhaust pipe assembly.

(b) Connect the center exhaust pipe assembly to the 2 exhaust pipe supports.

|

(c) Install the center exhaust pipe assembly to the front exhaust pipe assembly with the 2 bolts. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

4. INSTALL TAIL EXHAUST PIPE ASSEMBLY

|

(a) Using a vernier caliper, measure the free length of the compression springs. Minimum Free Length: 38.5 mm (1.52 in.) If the free length is less than the minimum, replace the compression spring. |

|

(b) Temporarily install a new gasket to the center exhaust pipe assembly.

|

(c) Using a plastic hammer and wooden block, tap in the gasket until its surface is flush with the center exhaust pipe assembly. Text in Illustration

NOTICE:

|

|

(d) Connect the tail exhaust pipe assembly to the 4 exhaust pipe supports.

|

(e) Install the tail exhaust pipe assembly to the center exhaust pipe assembly with the 2 bolts and 2 compression springs. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

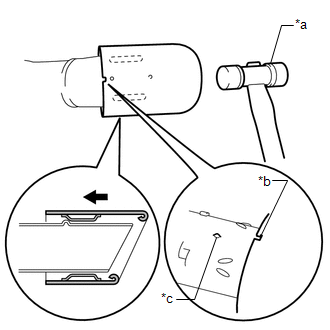

5. INSTALL TAIL EXHAUST PIPE BAFFLE SUB-ASSEMBLY

|

(a) Align the cutout of the tail exhaust pipe baffle sub-assembly with the protrusion of the tail exhaust pipe assembly as shown in the illustration. Text in Illustration

|

|

(b) Using a plastic hammer, uniformly tap the tail exhaust pipe baffle sub-assembly onto the tail exhaust pipe assembly.

6. INSPECT FOR EXHAUST GAS LEAK

If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.

(a) Perform "Inspection After Repair" after repairing an exhaust gas leak (See

page .gif) ).

).

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

Wear protective gloves when removing the exhaust pipe.

The exhaust pipe is extremely hot immediately after the engine has stopped.

...

Other materials about Toyota Venza:

Disposal

DISPOSAL

CAUTION / NOTICE / HINT

CAUTION:

Before performing pre-disposal deployment of any SRS component, review and closely

follow all applicable environmental and hazardous material regulations. Pre-disposal

deployment may be considered hazardous mate ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT DOOR BELT MOULDING

(a) Engage the 5 claws to install the front door belt moulding.

(b) Install the clip.

2. INSTALL FRONT DOOR GLASS RUN

3. INSTALL FRONT ...

Do-it-yourself service precautions

If you perform maintenance yourself, be sure to follow the correct procedure

given in these sections.

CAUTION

The engine compartment contains many mechanisms and fluids that may move suddenly,

become hot, or become electrically energized. To avoid de ...

0.115

.png)

.png)