Toyota Venza: Inspection

INSPECTION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the intake side and exhaust side.

PROCEDURE

1. INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

|

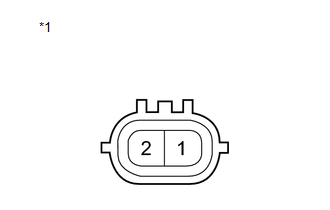

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the oil control valve assembly. Text in Illustration

|

|

|

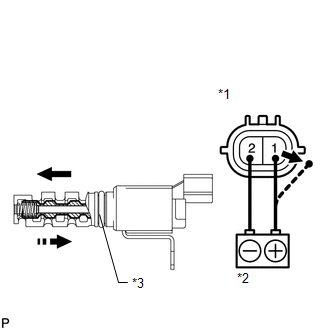

(b) Connect the positive (+) lead from a battery to terminal 1 and the negative (-) lead to terminal 2, and check the movement of the valve. OK:

NOTICE: Confirm that the valve moves freely and does not stick in any position. If necessary, replace the camshaft timing oil control valve assembly. HINT: Accumulation of foreign matter can cause minor pressure leaks. Minor pressure leaks will cause the camshaft to advance or retard, and this will cause a DTC to be set. Text in Illustration

|

|

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

2. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Exhaust Side)

(a) Disconnect the oil control valve connector.

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Exhaust Side)

(a) Apply a light coat of engine oil to a new O-ring, and install it

to the oil contro ...

Other materials about Toyota Venza:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Jam Protection Function Activates During Power Back Door Operation

DESCRIPTION

When the jam protection function activates during power back door operation,

one of the following may be the cause: 1) improper fit of back door, or a foreign

object is stuck in the back door, 2) malfunctioning power back door touch sensor

c ...

Brake Switch "B" Circuit High (P0724)

DESCRIPTION

The purpose of this circuit is to prevent the engine from stalling when brakes

are suddenly applied while driving in lock-up condition.

When the brake pedal is depressed, the stop light switch sends a signal to the

ECM. Then the ECM cancels t ...

0.1725