Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (w/o Smart Key System)

|

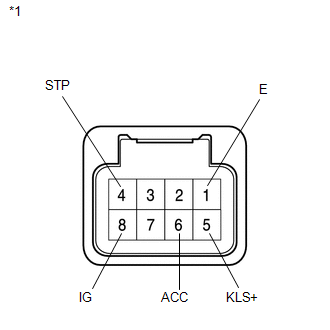

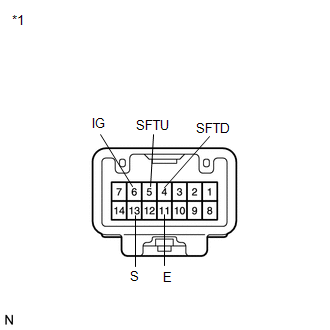

(a) Measure the voltage according to the value(s) in the table below. Text in Illustration

Standard Voltage:

HINT: Do not disconnect the shift lock control unit assembly connector. |

|

|

(b) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

HINT: Do not disconnect the shift lock control unit assembly connector. If the result is not as specified, replace the shift lever assembly. |

|

2. INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (w/ Smart Key System)

|

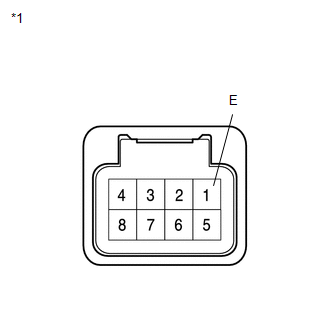

(a) Measure the voltage according to the value(s) in the table below. Text in Illustration

Standard Voltage:

HINT: Do not disconnect the shift lock control unit assembly connector. If the result is not as specified, replace the shift lock control unit assembly. |

|

|

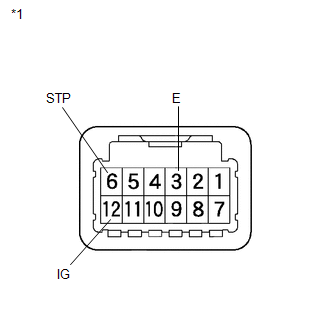

(b) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

HINT: Do not disconnect the shift lock control unit assembly connector. If the result is not as specified, replace the shift lock control unit assembly. |

|

3. INSPECT TRANSMISSION CONTROL SWITCH

|

(a) Measure the resistance between each terminal of the shift lock control unit assembly when the shift lever is moved to each position. Text in Illustration

Standard Resistance:

If the result is not as specified, replace the shift lock control unit assembly. |

|

4. INSPECT SHIFT LOCK SOLENOID

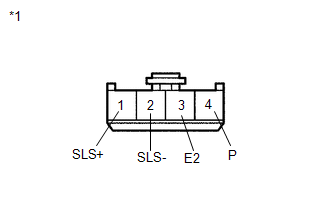

(a) Disconnect the shift lock solenoid connector.

|

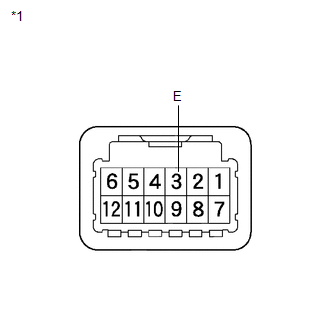

(b) Measure the resistance according to the value(s) in the table below when the shift lever is moved to each position. Text in Illustration

Standard Resistance:

If the result is not as specified, replace the shift lock control unit assembly. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (SLS+) - 2 (SLS-) |

Always |

112 Ω |

If the result is not as specified, replace the shift lock control unit assembly.

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. RE ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL SHIFT LEVER ASSEMBLY

NOTICE:

Check that the park/neutral position switch and the shift lever are in neutral.

(a) Slide the slider of the transmission ...

Other materials about Toyota Venza:

HD Radio Tuner Malfunction (B1551,B15A0,B15AD,B15B0,B15B3,B15B4,B15B7)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the navigation receiver assembly.

DTC No.

DTC Detection Condition

Trouble Area

B1551

When any of the following conditions is met:

...

Console Box Light

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Heater System)

3. REMOVE NO. 2 CONSOLE BOX CARPET

4. RE ...

Indicator Circuit

DESCRIPTION

The headlight beam level control system indicator light in the combination meter

assembly comes on for approximately 3 seconds when the ignition switch is turned

to ON. The indicator light also comes on when the headlight leveling ECU assembly ...

0.1404