Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT REAR WIPER MOTOR AND BRACKET ASSEMBLY

(a) Check the wiper low operation.

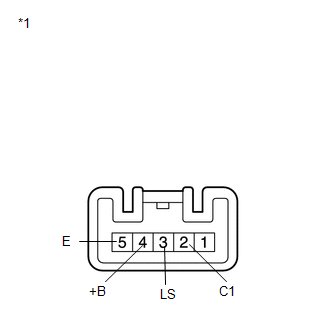

(1) Connect a battery positive (+) lead to terminal 4 (+B), and a negative (-) lead to terminal 3 (LS) and terminal 5 (E), and check that the motor operates.

OK:

Motor operates.

If the result is not as specified, replace the motor assembly.

(b) Check the intermittent operation.

(1) Connect a battery positive (+) lead to terminal 4 (+B), and a negative (-) lead to terminal 2 (C1) and terminal 5 (E), and check that the motor operates.

OK:

Motor operates.

If the result is not as specified, replace the rear wiper motor and bracket assembly.

Text in Illustration|

*1 |

Component without harness connected (Rear Wiper Motor and Bracket Assembly) |

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

2. REMOVE REAR WIPER ARM HEAD CAP

(a) Disengage the 4 claws and remove the rear wiper arm head cap as shown

in the illus ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR WIPER MOTOR AND BRACKET ASSEMBLY

(a) Install the rear wiper motor and bracket assembly with the 3 bolts.

Torque:

5.5 N·m {56 kgf·cm, 49 in ...

Other materials about Toyota Venza:

Open in Front Passenger Side Electrical Antenna Circuit (B27A2)

DESCRIPTION

The certification ECU (smart key ECU assembly) generates a request signal and

sends it to the door electrical key oscillator built into the front door outside

handle assembly (for front passenger side) at 0.25-second intervals. To detect a

k ...

Insufficient Coolant Temperature for Closed Loop Fuel Control (P0125)

DESCRIPTION

Refer to DTC P0115 (See page ).

DTC No.

DTC Detection Condition

Trouble Area

P0125

The engine coolant temperature does not reach the closed loop enabling

temperature for 20 minutes ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE NO. 2 ANTENNA CORD SUB-ASSEMBLY (w/o Sliding Roof)

2. REMOVE NO. 2 ANTENNA CORD SUB-ASSEMBLY (w/ Sliding Roof)

3. REMOVE VANITY LIGHT ASSEMBLY

(a) Remove the vanity light assembly (See page

).

HINT:

Use the same p ...

0.127