Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT TIE ROD ASSEMBLY LH

|

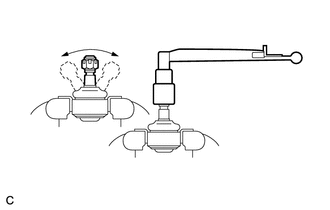

(a) Secure the tie rod assembly LH in a vise. |

|

(b) Install the nut to the stud bolt.

(c) Flip the ball joint back and forth 5 times.

(d) Set a torque wrench to the nut, turn the ball joint continuously at a rate of 2 to 4 seconds per turn, and check the turning torque on the 5th turn.

Standard turning torque:

0.49 to 3.43 N*m (5.0 to 35.0 kgf*cm, 4.3 to 30.3 in.*lbf)

HINT:

If the turning torque is not within the specified range, replace the tie rod assembly LH.

2. INSPECT TIE ROD ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

3. INSPECT TOTAL PRELOAD

|

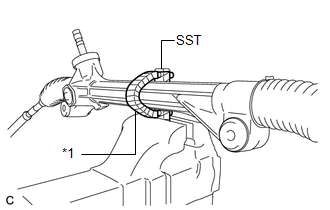

(a) Using SST, secure the steering link assembly in a vise. SST: 09612-00012 Text in Illustration

HINT: Tape SST before use. |

|

|

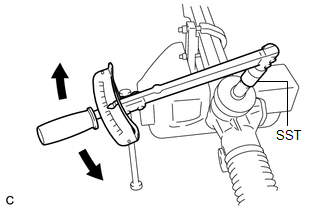

(b) Using SST and a torque wrench, inspect the total preload. SST: 09616-00020 Standard preload: 0.7 to 1.0 N*m (7.0 to 10.7 kgf*cm, 5.8 to 9.2 in.*lbf) NOTICE: Inspect the total preload around the steering rack center position. HINT: If the total preload is not within the specified range, replace the steering gear assembly with a new one. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE STEERING RACK BOOT CLIP (for LH Side)

(a) Using pliers, remove the steering rack boot clip.

2. REMOVE STEERING RACK BOOT CLIP (for RH Side)

HINT:

Perform the same ...

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

When disconnecting the steering intermediate shaft assembly and pinion shaft

of steering gear assembly, be sure to place matchmarks before servicing.

...

Other materials about Toyota Venza:

Sound Signal Circuit between Radio Receiver and Stereo Jack Adapter

DESCRIPTION

The No. 1 stereo jack adapter assembly sends the sound signal from an

external device to the radio and display receiver assembly via this circuit.

The sound signal that has been sent is amplified by the radio and display

receiver ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

(a) Turn the drive gear with 2 screwdrivers and make sure that it rotates

smoothly.

NOTICE:

Be careful not to damage the oil seal lip.

...

Installation

INSTALLATION

PROCEDURE

1. REPAIR INSTRUCTION

2. INSTALL REAR DOOR LOWER OUTSIDE STRIPE

(a) Refer to the illustration to position the rear door lower outside stripe.

Standard Measurement

Dimension

Measurement

A

...

0.1209