Toyota Venza: Air Fuel Ratio Sensor

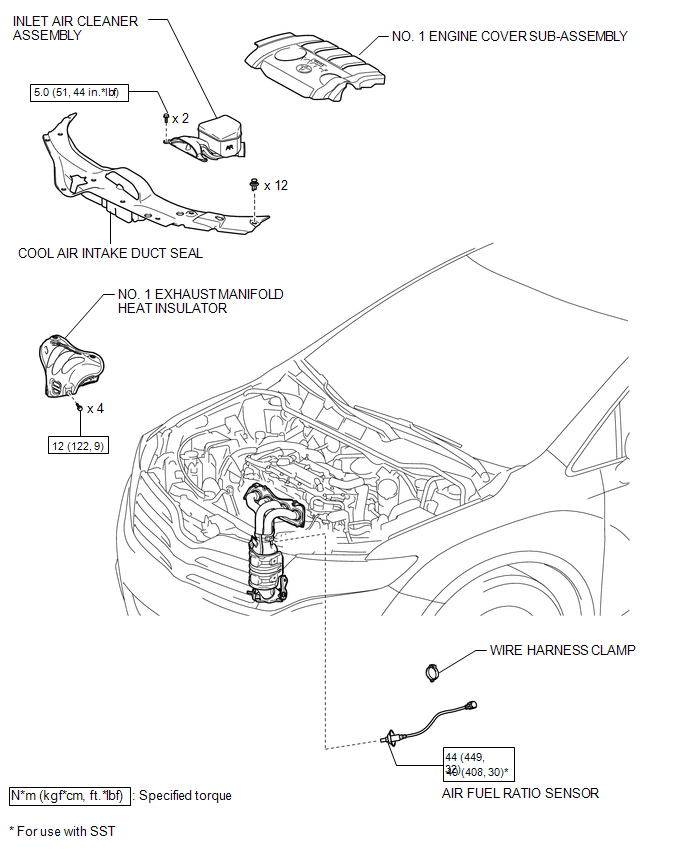

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

2. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

3. REMOVE INLET AIR CLEANER ASSEMBLY

.gif)

4. REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

.gif)

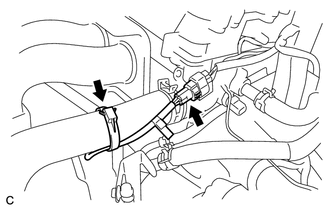

5. REMOVE AIR FUEL RATIO SENSOR

|

(a) Disconnect the air fuel ratio sensor connector. |

|

(b) Remove the wire harness clamp.

|

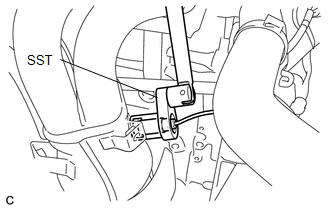

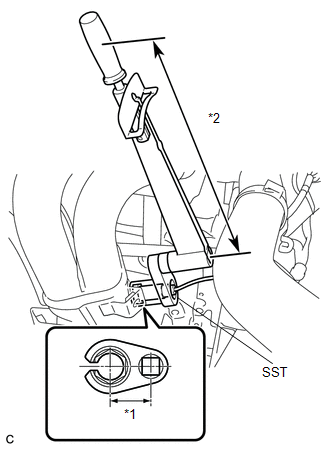

(c) Using SST, remove the air fuel ratio sensor from the exhaust manifold. SST: 09224-00011 |

|

Inspection

INSPECTION

PROCEDURE

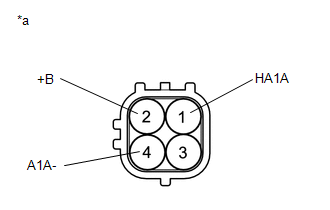

1. INSPECT AIR FUEL RATIO SENSOR (for Bank 1 Sensor 1)

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the air fuel ratio sensor. Text in Illustration

|

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL AIR FUEL RATIO SENSOR

|

(a) Using SST, install the air fuel ratio sensor to the exhaust manifold. Text in Illustration

SST: 09224-00011 Torque: without SST : 44 N┬Ęm {449 kgf┬Ęcm, 32 ft┬Ęlbf} with SST : 40 N┬Ęm {408 kgf┬Ęcm, 30 ft┬Ęlbf} NOTICE:

HINT: Perform "Inspection After Repair" after replacing the air fuel ratio

sensor (See page |

|

|

(b) Connect the air fuel ratio sensor connector. |

|

(c) Install the wire harness clamp.

2. INSPECT FOR EXHAUST GAS LEAK

3. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

.gif)

4. INSTALL INLET AIR CLEANER ASSEMBLY

.gif)

5. INSTALL COOL AIR INTAKE DUCT SEAL

.gif)

6. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

Accelerator Pedal

Accelerator Pedal

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT ACCELERATOR PEDAL SENSOR ASSEMBLY

(a) Connect the Techstream to the DLC3.

(b) Turn the ...

Other materials about Toyota Venza:

Dtc Check / Clear

DTC CHECK / CLEAR

1. CHECK DTC

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / (desired system) / Trouble Codes.

(e) Check the details of the DTC(s) ...

Transfer Case Front Oil Seal(for Rh Side)

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. DRAIN TRANSFER OIL

(a) Remove the transfer drain plug and gasket to drain the transfer oil.

(b) Install a new gasket and the transfer drain plug.

Torque:

49 N┬Ęm {500 kgf┬ ...

Fail-safe Chart

FAIL-SAFE CHART

1. FAIL-SAFE OPERATION

If there is a problem with sensor signals or actuator systems, the skid

control ECU prohibits power supply to the brake actuator assembly and informs

the ECM of VSC system malfunction.

The brake actuat ...

0.1647

.png)