Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT VACUUM SWITCHING VALVE ASSEMBLY (for ACIS)

|

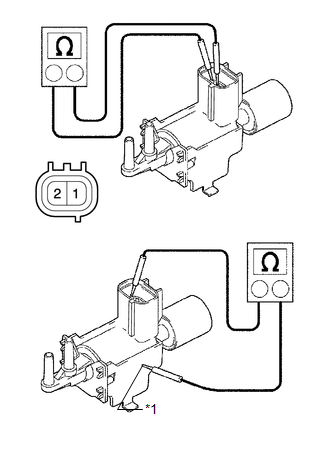

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the result is not as specified, replace the air cleaner assembly. |

|

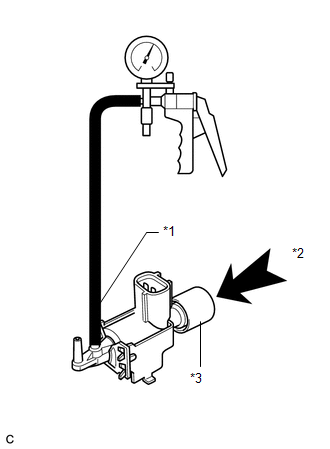

(b) Check the vacuum switching valve operation.

|

(1) When vacuum is applied to port E, check that air is sucked into the filter. Text in Illustration

If the result is not as specified, replace the air cleaner assembly. |

|

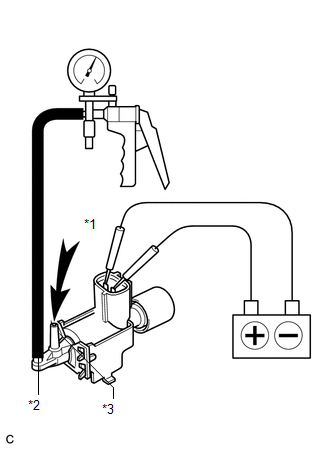

|

(2) Apply battery voltage across the terminals. When vacuum is applied to port F, check that air is sucked into port E. Text in Illustration

If the result is not as specified, replace the air cleaner assembly. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WIPER ARM HEAD CAP

2. REMOVE FRONT WIPER ARM AND BLADE ASSEMBLY LH

3. REMOVE FRONT WIPER ARM AND BLADE ASSEMBLY RH

4. REMOVE FRONT FENDER TO COWL SIDE S ...

Other materials about Toyota Venza:

Windshield Deicer does not Operate

DESCRIPTION

When the rear window defogger switch on the air conditioning control assembly

is pressed, the operation signal is transmitted to the air conditioning amplifier

assembly through the LIN communication line. When the air conditioning amplifier

...

Terminals Of Ecu

TERMINALS OF ECU

1. TERMINALS OF ECU

Text in Illustration

*1

Component without harness connected

(Brake Actuator (Skid Control ECU))

Terminal No. (Symbol)

Terminal Description

1 (GND ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 2 STEERING RACK BOOT

(a) Apply lithium soap base glycol grease to the inside of the small

opening of a new No. 2 steering rack boot.

(b) Install the No. 2 ste ...

0.1235