Toyota Venza: Inspection

INSPECTION

PROCEDURE

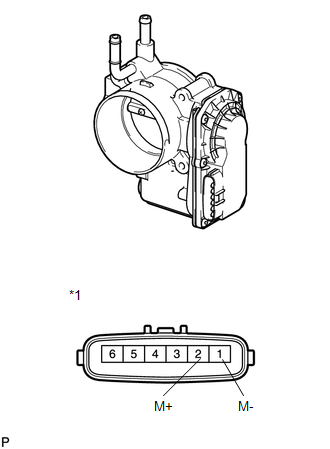

1. INSPECT THROTTLE BODY ASSEMBLY

Text in Illustration

Text in Illustration

|

*1 |

Component without harness connected (Throttle Body) |

(a) Check that the throttle valve opens and closes smoothly.

(b) Check that there is no sludge accumulating around the throttle body.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (M-) - 2 (M+) |

20°C (68°F) |

0.3 to 100 Ω |

If the result is not as specified, replace the throttle body assembly.

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK THROTTLE BODY ASSEMBLY

(a) Check the throttle control motor operating sounds.

(1) Turn the ignition switch to ON.

(2) When pressing the accelerator pedal, ...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE WINDSHIELD WIPER MOTOR AND LINK

(a) Remove the windshield wiper motor and link (See page

).

2. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

3. REMOVE NO. 1 ENGINE COV ...

Other materials about Toyota Venza:

Sound Signal Circuit between Navigation Receiver Assembly and Stereo Jack Adapter

DESCRIPTION

The No. 1 stereo jack adapter assembly sends the sound signal from an external

device to the navigation receiver assembly via this circuit.

The sound signal that has been sent is amplified by the navigation receiver assembly

and then is sent ...

Transmitter ID1 Operation Stop (C2111/11-C2114/14)

DESCRIPTION

The tire pressure warning valve and transmitter installed in each tire and wheel

assembly measures the tire pressures. The measured values are transmitted as radio

waves to the tire pressure warning antenna and receiver on the body and then se ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL POWER DISTRIBUTION

(a) Connect the 3 connectors.

(b) Engage the 2 claws to temporarily install the power distribution

as shown in the illustration.

...

0.1238