Toyota Venza: Horn System

Precaution

PRECAUTION

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize the following system after the cable is reconnected.

|

System Name |

See Procedure |

|---|---|

|

Back Door Closer System |

|

|

Power Back Door System |

1. EXPRESSIONS OF IGNITION SWITCH

The type of ignition switch used on this model differs according to the specifications of the vehicle. The expressions listed in the table below are used in this section.

|

Expression |

Switch Type |

|

|---|---|---|

|

Ignition Switch (Position) |

Engine Switch (Condition) |

|

|

Ignition Switch off |

LOCK |

Off |

|

Ignition Switch ON |

ON |

On (IG) |

|

Ignition Switch ACC |

ACC |

On (ACC) |

|

Engine Start |

START |

On (Start) |

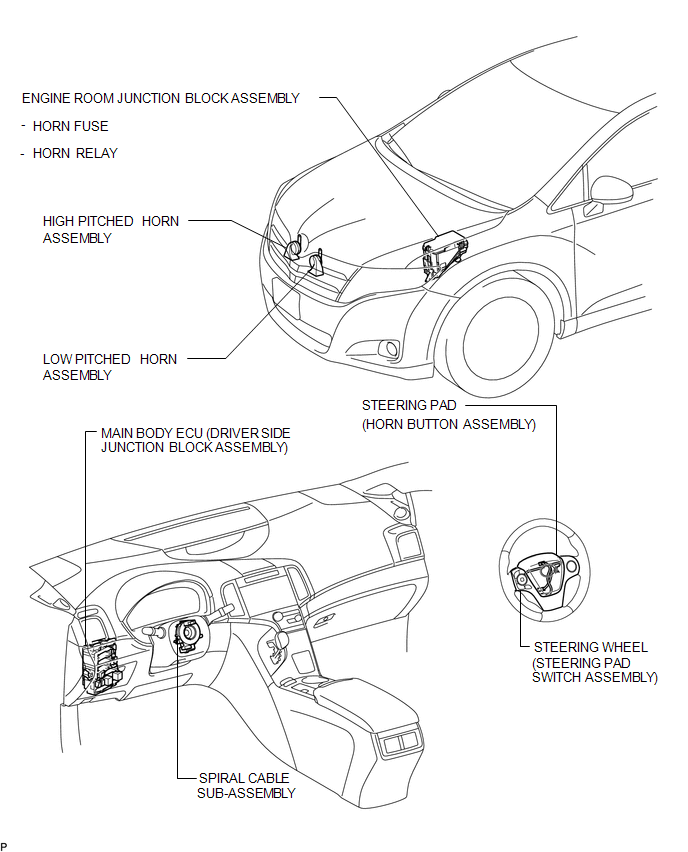

Parts Location

PARTS LOCATION

ILLUSTRATION

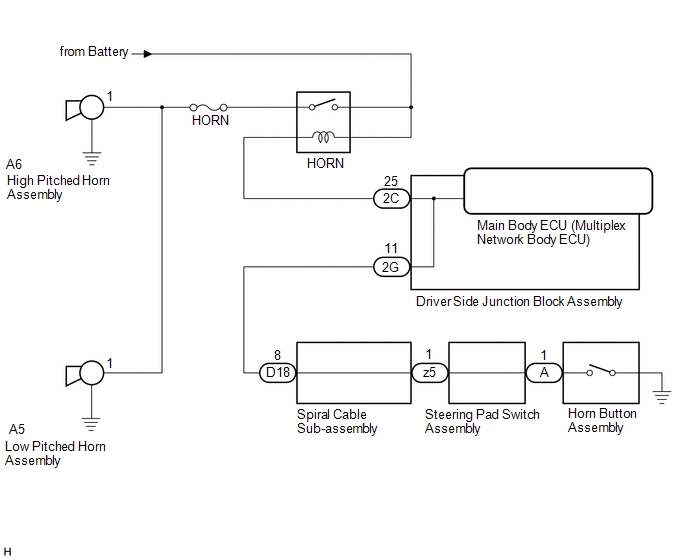

System Diagram

SYSTEM DIAGRAM

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms are listed in order of probability in the "Suspected Area" column of the table. Check each symptom by checking the suspected areas in the order they are listed. Replace parts as necessary.

HORN SYSTEM|

Symptom |

Suspected Area |

See page |

|---|---|---|

|

Horn does not sound |

HORN fuse |

- |

|

HORN relay (Engine room junction block assembly) |

|

|

|

Horn button assembly |

|

|

|

Steering pad switch assembly |

|

|

|

Spiral cable sub-assembly |

|

|

|

Wire harness |

- |

|

|

Horn sounds all the time |

HORN relay (Engine room junction block assembly) |

|

|

Horn button assembly |

|

|

|

Steering pad switch assembly |

|

|

|

Spiral cable sub-assembly |

|

|

|

Wire harness |

- |

|

|

Low pitched horn operates but high pitched horn does not operate |

High pitched horn assembly |

|

|

Wire harness |

- |

|

|

High pitched horn operates but low pitched horn does not operate |

Low pitched horn assembly |

|

|

Wire harness |

- |

Horn

Horn

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT LOW PITCHED HORN ASSEMBLY

(a) Apply battery voltage and check the operation of the low pitched

...

Relay

Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT HORN RELAY (ENGINE ROOM JUNCTION BLOCK ASSEMBLY)

(a) Remove the engine room junction block assembly from the engine ro ...

Other materials about Toyota Venza:

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE STEERING RACK BOOT CLIP (for LH Side)

(a) Using pliers, remove the steering rack boot clip.

2. REMOVE STEERING RACK BOOT CLIP (for RH Side)

HINT:

Perform the same procedure as for the LH side.

3. REMOVE NO. 2 STEERING RAC ...

Throttle Actuator Control Motor Circuit Low (P2102,P2103)

DESCRIPTION

The throttle actuator is operated by the ECM and opens and closes the throttle

valve using gears.

The opening angle of the throttle valve is detected by the throttle position

sensor, which is mounted on the throttle body. The throttle positio ...

0.1195

.gif)

.gif)