Toyota Venza: Horn

Components

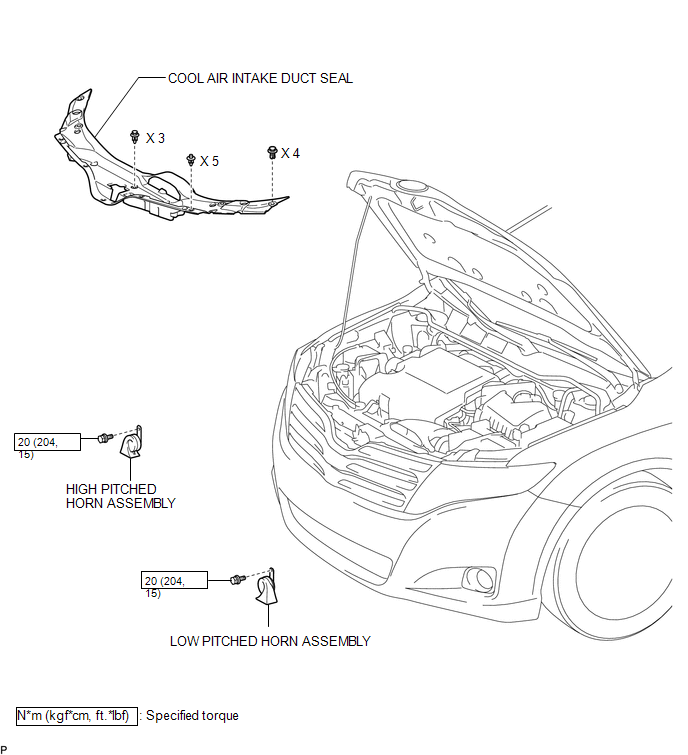

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

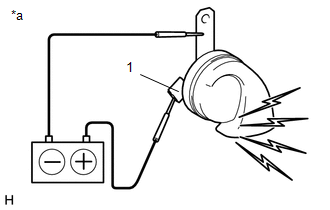

1. INSPECT LOW PITCHED HORN ASSEMBLY

|

(a) Apply battery voltage and check the operation of the low pitched horn assembly according to the table below. OK:

If the result is not as specified, replace the low pitched horn assembly. |

|

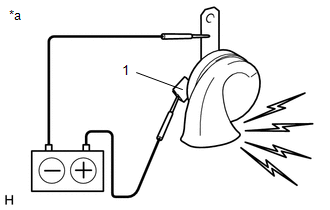

2. INSPECT HIGH PITCHED HORN ASSEMBLY

|

(a) Apply battery voltage and check the operation of the high pitched horn assembly according to the table below. OK:

If the result is not as specified, replace the high pitched horn assembly. |

|

Removal

REMOVAL

PROCEDURE

1. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

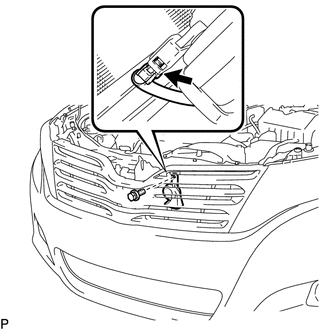

2. REMOVE LOW PITCHED HORN ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the bolt and low pitched horn assembly.

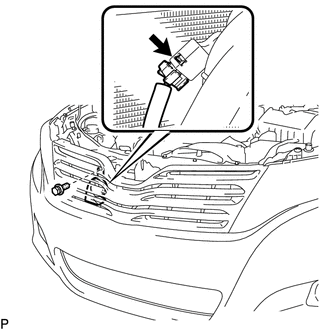

3. REMOVE HIGH PITCHED HORN ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the bolt and high pitched horn assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL LOW PITCHED HORN ASSEMBLY

(a) Install the low pitched horn assembly with the bolt.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

(b) Connect the connector.

2. INSTALL HIGH PITCHED HORN ASSEMBLY

(a) Install the high pitched horn assembly with the bolt.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

(b) Connect the connector.

3. INSTALL COOL AIR INTAKE DUCT SEAL

.gif)

Horn

Horn

...

Horn System

Horn System

Precaution

PRECAUTION

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following system after the cable is reconnected.

System Name

...

Other materials about Toyota Venza:

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT REAR WIPER MOTOR AND BRACKET ASSEMBLY

(a) Operate the rear wiper motor and bracket assembly.

(b) Stop the rear wiper motor and bracket assembly operation.

...

Pressure Control Solenoid "G" Performance (Shift Solenoid Valve SL4) (P2808)

DESCRIPTION

The TCM uses the vehicle speed signal and signals from the transmission speed

sensors (NC, NT) to detect the actual gear (1st, 2nd, 3rd, 4th, 5th or 6th gear).

Then the TCM compares the actual gear with the shift schedule in the TCM memory

to ...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

0.175