Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

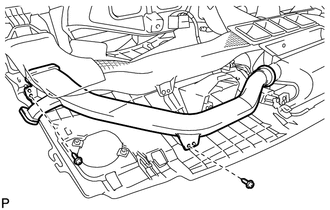

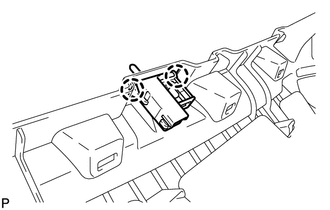

1. REMOVE NO. 1 SIDE DEFROSTER NOZZLE DUCT

|

(a) Remove the 2 screws <E> or <F> and remove the No. 1 side defroster nozzle duct. |

|

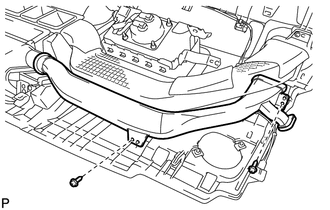

2. REMOVE NO. 2 SIDE DEFROSTER NOZZLE DUCT

|

(a) Remove the 2 screws <E> or <F> and remove the No. 2 side defroster nozzle duct. |

|

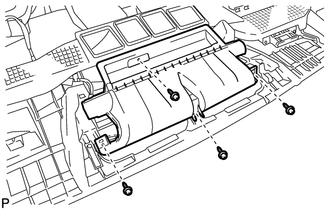

3. REMOVE DEFROSTER NOZZLE ASSEMBLY

|

(a) Remove the 4 screws <E> or <F> and remove the defroster nozzle assembly. |

|

4. REMOVE HEATER TO REGISTER DUCT

(a) Remove the 7 screws <E> or <F> and remove the heater to register duct.

5. REMOVE NO. 1 ANTENNA CORD SUB-ASSEMBLY

.gif)

6. REMOVE NAVIGATION ANTENNA ASSEMBLY (w/ Navigation System)

.gif)

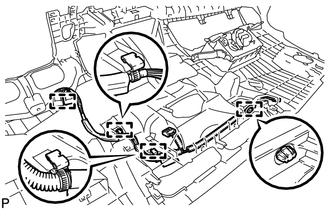

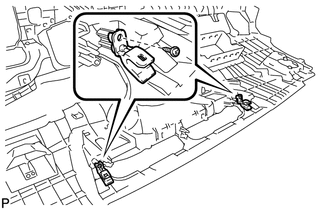

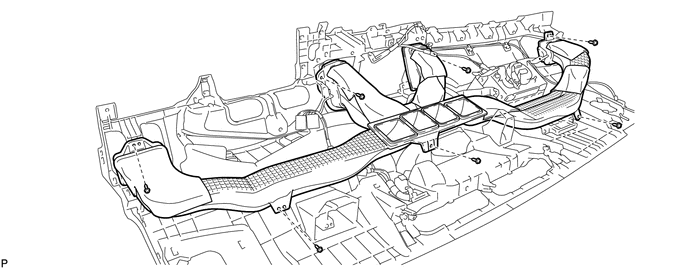

7. REMOVE NO. 3 INSTRUMENT PANEL WIRE

|

(a) Disengage the 4 clamps and remove the No. 3 instrument panel wire. |

|

8. REMOVE FRONT PASSENGER AIRBAG ASSEMBLY

.gif)

9. REMOVE GLOVE BOX LIGHT ASSEMBLY

|

(a) Disengage the 2 claws and remove the glove box light assembly. |

|

10. REMOVE NO. 1 INSTRUMENT PANEL PIN

|

(a) Remove the 2 screws <E> or <F> and the 2 No. 1 instrument panel pins. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

(See page )

2. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

3. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 1 INSTRUMENT PANEL PIN

(a) Install the 2 No. 1 instrument panel pins with the 2 screws <E> or

<F>.

...

Other materials about Toyota Venza:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" column ...

Theft Deterrent System Communication Line High Fixation (B279A)

DESCRIPTION

If the communication line (EFIO - IMI) to the certification ECU (smart key ECU

assembly) is stuck high output (e.g. shorted to +B), the ECM stores this DTC.

DTC No.

DTC Detection Condition

Trouble Area

...

Registered Device cannot be Deleted

PROCEDURE

1.

DELETE OPERATION

(a) Check if a registered portable player can be deleted normally.

OK:

Registered portable player can be deleted normally.

OK

END

NG

PROCEED TO ...

0.1365