Toyota Venza: Front Occupant Classification Sensor RH Collision Detection (B1786)

DESCRIPTION

DTC B1786 is output when the occupant classification ECU receives a collision detection signal sent by the front occupant classification sensor RH if an accident occurs.

DTC B1786 is also output when the front seat assembly RH is subjected to a strong impact, even if an actual accident does not occur.

However, when the occupant classification ECU outputs a collision detection signal, even if the vehicle is not in a collision, DTC B1786 can be cleared by Zero Point Calibration and Sensitivity Check.

Therefore, if DTC B1786 is output, first perform Zero Point Calibration and Sensitivity Check.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B1786 |

|

|

HINT:

When DTC B1650/32 is detected as a result of troubleshooting for the airbag system, check the DTCs stored in the occupant classification ECU. When DTC B1786 is output, perform troubleshooting for the DTC.

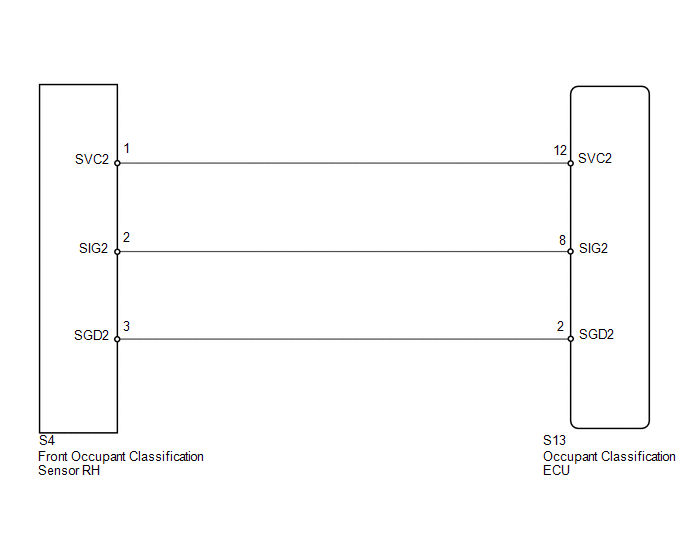

WIRING DIAGRAM

PROCEDURE

|

1. |

PERFORM ZERO POINT CALIBRATION |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Using the Techstream, perform Zero Point Calibration (See page

.gif) ).

).

OK:

"Zero Point Calibration is complete." is displayed.

| NG | .gif) |

GO TO STEP 4 |

|

|

2. |

PERFORM SENSITIVITY CHECK |

(a) Using the Techstream, perform Sensitivity Check (See page

.gif) ).

).

Standard:

27 to 33 kg (59.5 to 72.8 lb)

| NG | .gif) |

GO TO STEP 4 |

|

|

3. |

CHECK DTC |

(a) Turn the ignition switch to ON.

(b) Clear the DTCs stored in the occupant classification ECU (See page

.gif) ).

).

(c) Clear the DTCs stored in the center airbag sensor assembly (See page

.gif) ).

).

(d) Turn the ignition switch off.

(e) Turn the ignition switch to ON.

(f) Check for DTCs (See page .gif) ).

).

OK:

DTC B1786 is not output.

HINT:

Codes other than DTC B1786 may be output at this time, but they are not related to this check.

| OK | .gif) |

END |

|

|

4. |

REPLACE FRONT SEAT FRAME WITH ADJUSTER ASSEMBLY RH |

(a) Turn the ignition switch off.

(b) Disconnect the cable from the negative (-) battery terminal.

(c) Replace the front seat frame with adjuster assembly RH (See page

.gif) for power seat or

for power seat or

.gif) for manual seat).

for manual seat).

HINT:

Perform the inspection using parts from a normal vehicle if possible.

|

|

5. |

PERFORM ZERO POINT CALIBRATION |

(a) Connect the cable to the negative (-) battery terminal.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Using the Techstream, perform Zero Point Calibration (See page

.gif) ).

).

OK:

"Zero Point Calibration is complete." is displayed.

| NG | .gif) |

GO TO STEP 8 |

|

|

6. |

PERFORM SENSITIVITY CHECK |

(a) Using the Techstream, perform Sensitivity Check (See page

.gif) ).

).

Standard:

27 to 33 kg (59.5 to 72.8 lb)

| NG | .gif) |

GO TO STEP 8 |

|

|

7. |

CHECK DTC |

(a) Turn the ignition switch to ON.

(b) Clear the DTCs stored in the occupant classification ECU (See page

.gif) ).

).

(c) Clear the DTCs stored in the center airbag sensor assembly (See page

.gif) ).

).

(d) Turn the ignition switch off.

(e) Turn the ignition switch to ON.

(f) Check for DTCs (See page .gif) ).

).

OK:

DTC B1786 is not output.

HINT:

Codes other than DTC B1786 may be output at this time, but they are not related to this check.

| OK | .gif) |

END |

|

|

8. |

REPLACE OCCUPANT CLASSIFICATION ECU |

(a) Turn the ignition switch off.

(b) Disconnect the cable from the negative (-) battery terminal.

(c) Replace the occupant classification ECU (See page

.gif) ).

).

|

|

9. |

PERFORM ZERO POINT CALIBRATION |

(a) Connect the cable to the negative (-) battery terminal.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Using the Techstream, perform Zero Point Calibration (See page

.gif) ).

).

OK:

"Zero Point Calibration is complete." is displayed.

|

|

10. |

PERFORM SENSITIVITY CHECK |

(a) Using the Techstream, perform Sensitivity Check (See page

.gif) ).

).

Standard:

27 to 33 kg (59.5 to 72.8 lb)

| NEXT | .gif) |

END |

Rear Occupant Classification Sensor RH Collision Detection (B1788)

Rear Occupant Classification Sensor RH Collision Detection (B1788)

DESCRIPTION

DTC B1788 is output when the occupant classification ECU receives a collision

detection signal sent by the rear occupant classification sensor RH if an accident

occurs.

DTC B1788 is ...

Front Occupant Classification Sensor LH Collision Detection (B1785)

Front Occupant Classification Sensor LH Collision Detection (B1785)

DESCRIPTION

DTC B1785 is output when the occupant classification ECU receives a collision

detection signal sent by the front occupant classification sensor LH if an accident

occurs.

DTC B1785 is ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT SUSPENSION MEMBER BODY MOUNTING REAR CUSHION LH

(a) Temporarily install a new front suspension member body mounting rear

cushion LH while confirming the installation direction.

NOTICE:

Position th ...

One or more Power Seat Motors do not Operate

DESCRIPTION

Signals are input into the position control ECU and switch assembly. The built-in

ECU manages the signals received from the position control ECU and switch assembly,

and operates each motor. If the position control ECU and switch assembly rece ...

System Description

SYSTEM DESCRIPTION

CAUTION:

If using a pacemaker, be sure to read the manual of the pacemaker before using

the key, as the radio waves of the key may affect the pacemaker.

1. SMART KEY SYSTEM DESCRIPTION

(a) In addition to conventional mechanical key and ...

0.1461

.gif)