Toyota Venza: Drive Belt

Components

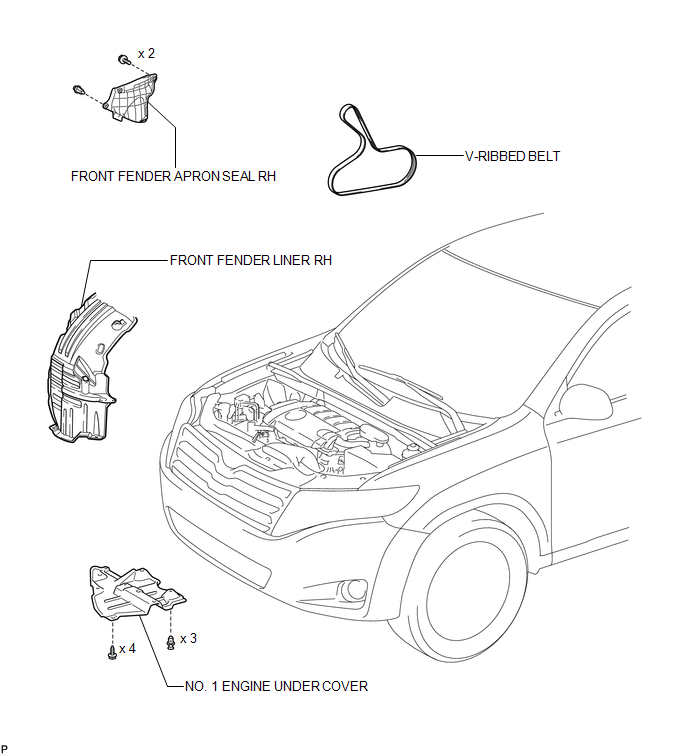

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT V-RIBBED BELT

|

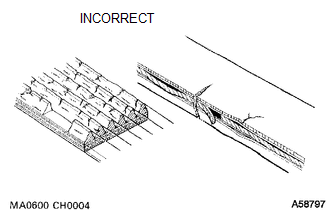

(a) Check the belt for wear, cracks or other signs of damage. If any of the following defects is found, replace the V-ribbed belt.

|

|

|

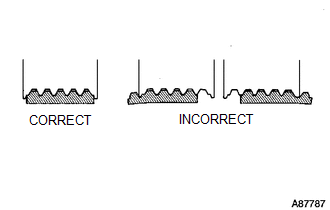

(b) Check that the belt fits properly in the ribbed grooves. HINT: Check with your hand to confirm that the belt has not slipped out of the groove on the bottom of the pulley. If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt correctly. |

|

2. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY

(a) Check that nothing gets caught in the tensioner by turning it clockwise and counterclockwise.

If a malfunction exists, replace the V-ribbed belt tensioner.

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL RH

2. REMOVE NO. 1 ENGINE UNDER COVER

3. SEPARATE FRONT FENDER LINER RH

4. REMOVE FRONT FENDER APRON SEAL RH

.gif)

5. REMOVE V-RIBBED BELT

|

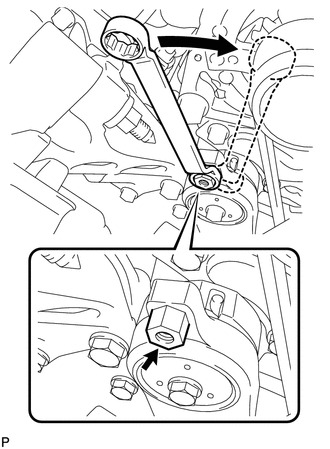

(a) Attach a wrench to the hexagonal portion of the belt tensioner as shown in the illustration, rotate the belt tensioner clockwise, and remove the V-ribbed belt. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL V-RIBBED BELT

|

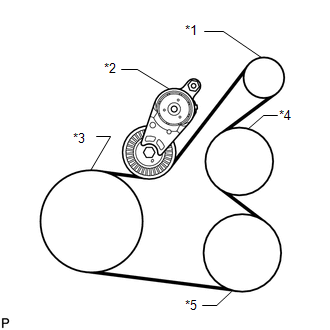

(a) Set the V-ribbed belt onto each part as shown in the illustration except the water pump pulley. Text in Illustration

|

|

(b) Loosen the V-ribbed belt by turning the belt tensioner clockwise.

(c) Set the V-ribbed belt onto the water pump pulley.

NOTICE:

Make sure that the belt is attached to each pulley. In particular, make sure that the belt is securely fitted into the grooves of the crankshaft pulley.

2. INSTALL FRONT FENDER APRON SEAL RH

.gif)

3. INSTALL FRONT FENDER LINER RH

4. INSTALL NO. 1 ENGINE UNDER COVER

5. INSTALL FRONT WHEEL RH

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the camshaft, No. 2 camshaft,

camshaft timing gear assembly, camshaft timing exhaust gear as ...

Engine

Engine

...

Other materials about Toyota Venza:

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK AIR CONDITIONING AMPLIFIER ASSEMBLY

(a) Disconnect the D47 air conditioning amplifier assembly connector.

(b) Measure the voltage and resistance according to the value(s) in the table

below.

HINT:

Measure the values on the wi ...

Throttle Actuator Control Motor Current Range / Performance (P2118)

DESCRIPTION

The electronic throttle control system has a dedicated power supply circuit.

The voltage (+BM) is monitored and when it is low (below 4 V), the ECM determines

that there is a malfunction in the electronic throttle control system and cuts off

...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

The TCM of this system is connected to the CAN communication system.

Therefore, before starting troubleshooting, make sure to check that there

is no trouble in the CAN and multiplex communication system.

*: U ...

0.171