Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

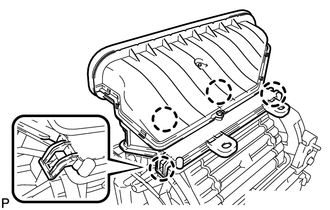

1. REMOVE NO. 1 AIR DUCT SUB-ASSEMBLY

|

(a) Disengage the 4 claws and remove the No. 1 air duct sub-assembly. |

|

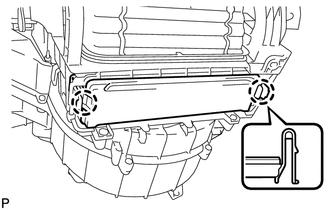

2. REMOVE AIR FILTER COVER PLATE

|

(a) Disengage the 2 claws and remove the air filter cover plate. |

|

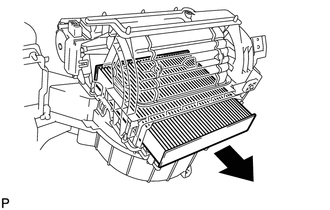

3. REMOVE CLEAN AIR FILTER

|

(a) Remove the clean air filter as shown in the illustration. |

|

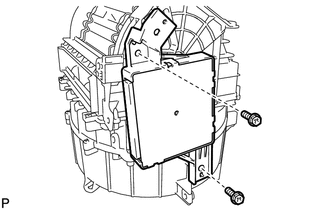

4. REMOVE AIR CONDITIONING AMPLIFIER ASSEMBLY

|

(a) Remove the 2 screws and air conditioning amplifier assembly. |

|

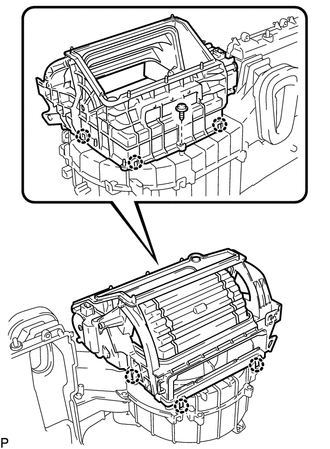

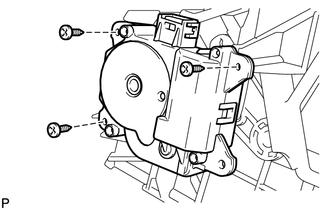

5. REMOVE AIR INLET SERVO MOTOR SUB-ASSEMBLY

|

(a) Remove the screw. |

|

(b) Disengage the 6 claws and remove the blower case.

|

(c) Remove the 3 screws and air inlet servo motor sub-assembly. |

|

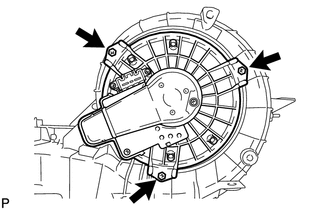

6. REMOVE FRONT BLOWER MOTOR SUB-ASSEMBLY

|

(a) Remove the 3 screws and front blower motor sub-assembly. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE AIR CONDITIONING UNIT ASSEMBLY

(See page )

2. REMOVE NO. 1 FINISH PANEL MOUNTING BRACKET

3. REMOVE NO. 2 FINISH PANEL MOUNTING BRACKET

4. REMOVE NO. 3 AIR DUCT ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT BLOWER MOTOR SUB-ASSEMBLY

(a) Install the front blower motor sub-assembly with the 3 screws.

2. INST ...

Other materials about Toyota Venza:

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT SEAT WIRE

(a) Engage the 2 clamps to install the front seat wire.

(b) Connect the 4 connectors.

2. INSTALL OCCUPANT CLASSIFICATION ECU

3. INSTALL FRONT LOW ...

System Diagram

SYSTEM DIAGRAM

1. MIRROR CONTROL SYSTEM

Communication Table

Sender

Receiver

Signal / Signal Condition

Line

Main body ECU (driver side junction block assembly)

Outer mirror control EC ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds aft ...

0.12