Toyota Venza: Daytime Running Light Relay Circuit

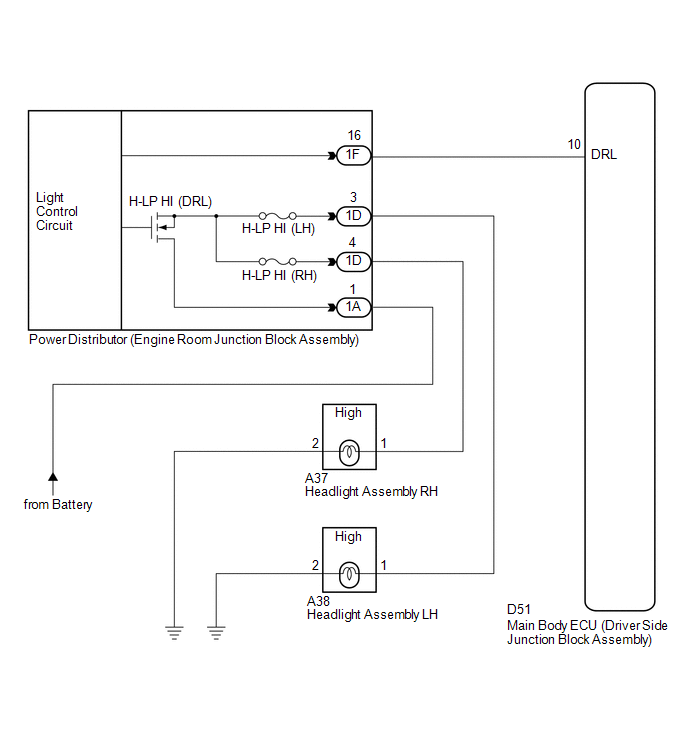

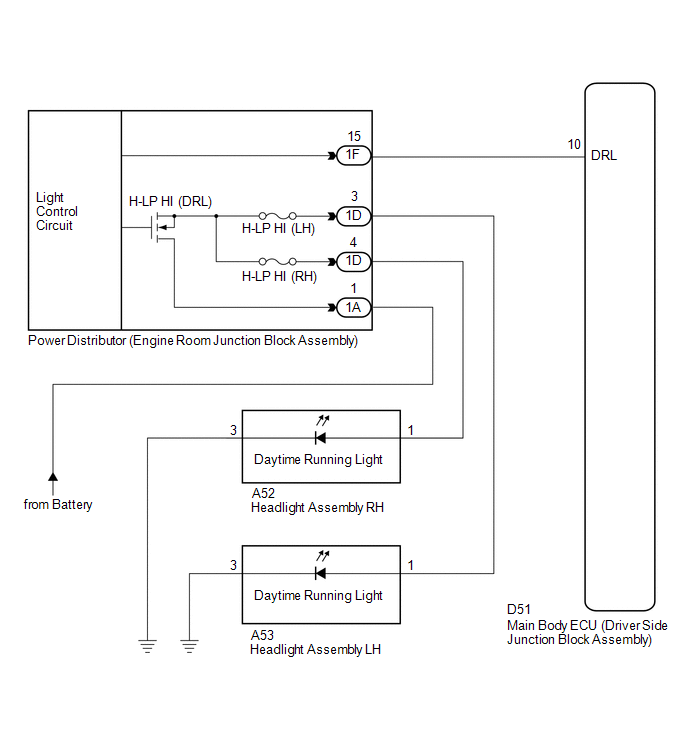

DESCRIPTION

The main body ECU (driver side junction block assembly) controls the daytime running lights.

WIRING DIAGRAM

1. for Halogen Headlight

2. for HID Headlight

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Active Test.

(e) Check that the relay operates.

Main Body|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Daytime Running Light |

Daytime running light relay |

ON/OFF |

- |

OK:

Relay operates. (Daytime running lights illuminate.)

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (for Halogen Headlight) |

B |

|

NG (for HID Headlight) |

C |

| A | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| C | .gif) |

GO TO STEP 5 |

|

|

2. |

CHECK HEADLIGHT |

(a) Check the operation of the high beam headlights.

OK:

High beam headlights operate normally.

| NG | .gif) |

GO TO PROBLEM SYMPTOMS TABLE |

|

|

3. |

INSPECT POWER DISTRIBUTOR (ENGINE ROOM JUNCTION BLOCK ASSEMBLY) |

|

(a) Remove the power distributor (engine room junction block assembly)

from the engine room relay block (See page

|

|

(b) Connect a positive (+) lead from the battery to terminal 1A-1.

(c) Connect a negative (-) lead from the battery to terminal 1F-16.

(d) Check for pulses according to the value(s) in the table below.

Standard:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1D-3 - Battery negative |

Always |

Pulse generation |

|

1D-4 - Battery negative |

Always |

Pulse generation |

|

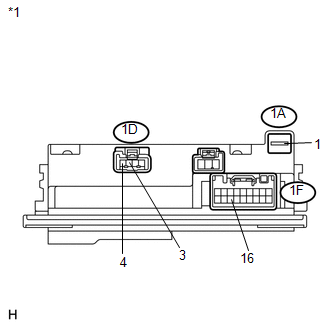

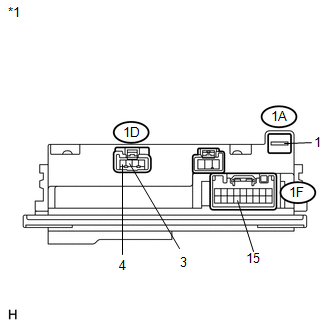

*1 |

Component without harness connected (Power Distributor (Engine Room Junction Block Assembly)) |

| NG | .gif) |

REPLACE POWER DISTRIBUTOR (ENGINE ROOM JUNCTION BLOCK ASSEMBLY) |

|

|

4. |

CHECK HARNESS AND CONNECTOR (ENGINE ROOM JUNCTION BLOCK ASSEMBLY - MAIN BODY ECU) |

|

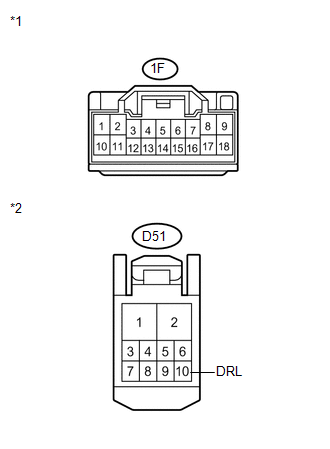

(a) Disconnect the 1F power distributor (engine room junction block assembly) connector. |

|

(b) Disconnect the D51 main body ECU (driver side junction block assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1F-16 - D51-10 (DRL) |

Always |

Below 1 Ω |

|

D51-10 (DRL) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Power Distributor (Engine Room Junction Block Assembly)) |

|

*2 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

| OK | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

5. |

INSPECT POWER DISTRIBUTOR (ENGINE ROOM JUNCTION BLOCK ASSEMBLY) |

|

(a) Remove the power distributor (engine room junction block assembly)

from the engine room relay block (See page

|

|

(b) Connect a positive (+) lead from the battery to terminal 1A-1.

(c) Connect a negative (-) lead from the battery to terminal 1F-15.

(d) Check for pulses according to the value(s) in the table below.

Standard:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1D-3 - Battery negative |

Always |

Pulse generation |

|

1D-4 - Battery negative |

Always |

Pulse generation |

|

*1 |

Component without harness connected (Power Distributor (Engine Room Junction Block Assembly)) |

| NG | .gif) |

REPLACE POWER DISTRIBUTOR (ENGINE ROOM JUNCTION BLOCK ASSEMBLY) |

|

|

6. |

CHECK HARNESS AND CONNECTOR (ENGINE ROOM JUNCTION BLOCK ASSEMBLY - MAIN BODY ECU) |

|

(a) Disconnect the 1F power distributor (engine room junction block assembly) connector. |

|

(b) Disconnect the D51 main body ECU (driver side junction block assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1F-15 - D51-10 (DRL) |

Always |

Below 1 Ω |

|

D51-10 (DRL) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Power Distributor (Engine Room Junction Block Assembly)) |

|

*2 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

| OK | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Headlight Solenoid Circuit

Headlight Solenoid Circuit

DESCRIPTION

for HID Headlight:

When the main body ECU receives a high beam turn on signal, the main

body ECU activates the bi-function by controlling the BI-XENON relay. The

bi-func ...

Headlight (HI-BEAM) Circuit

Headlight (HI-BEAM) Circuit

DESCRIPTION

for Halogen Headlight:

The main body ECU (driver side junction block assembly) controls the

high beam headlights.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE ...

Other materials about Toyota Venza:

Speed Sensor(when Using The Engine Support Bridge)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

See page

2. REMOVE SPEED SENSOR

(a) Disconnect the speed sensor connector.

(b) Remove the 2 bolts and speed sensor from the tra ...

Portable Player cannot be Connected Manually/Automatically

CAUTION / NOTICE / HINT

HINT:

Some versions of "Bluetooth" compatible audio players may not function properly,

or the functions may be limited using the radio and display receiver assembly, even

if the portable audio player itself can play file ...

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery terminal. Therefore, make sure to read the

disconnecting the cable from the negativ ...

0.1198

.gif)

.gif) ).

).