Toyota Venza: Back Door Support

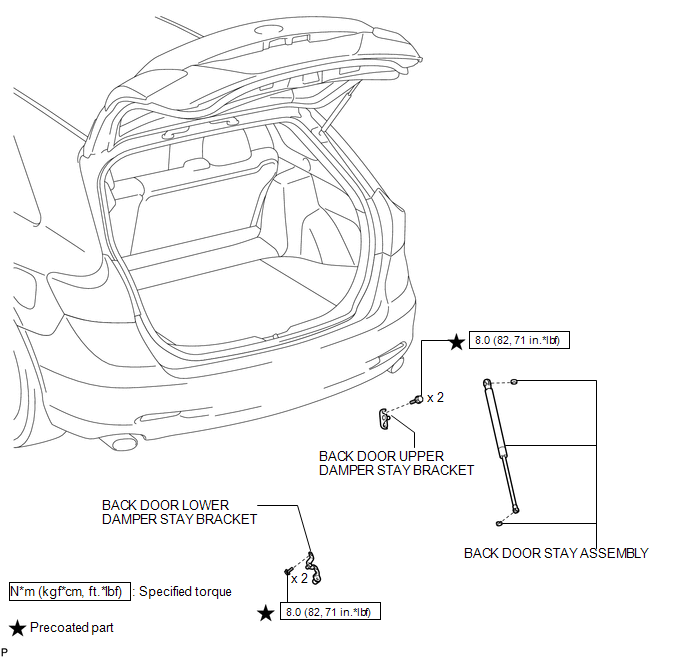

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR STAY ASSEMBLY

NOTICE:

- Avoid touching the piston rod as much as possible to prevent foreign matter from attaching to it. Be sure to hold the cylinder while servicing.

- Do not wear cotton gloves or other similar materials when handling the piston rod. Fibers may attach to the rod and result in gas leaks.

- Do not apply any horizontal load to the door stay in order to prevent the piston rod from deforming.

|

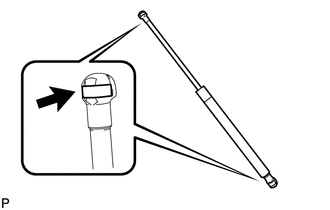

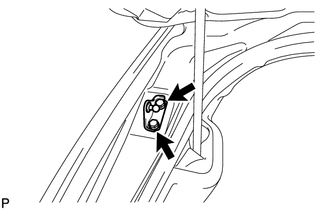

(a) Using a screwdriver, remove the stop ring along the groove. HINT: Tape the screwdriver tip before use. Text in Illustration

|

|

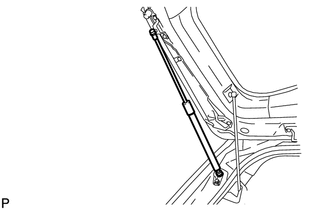

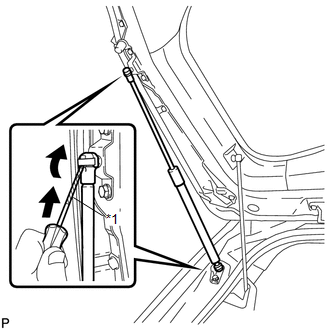

(b) Release the ball joint and remove the back door stay assembly.

NOTICE:

Remove the back door stay assembly while supporting the back door by hand.

2. REMOVE BACK DOOR LOWER DAMPER STAY BRACKET

|

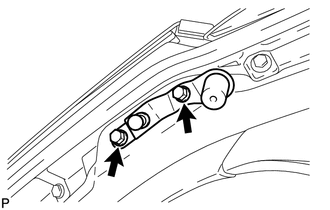

(a) Remove the 2 bolts and back door lower damper stay bracket. |

|

3. REMOVE BACK DOOR UPPER DAMPER STAY BRACKET

|

(a) Remove the 2 bolts and back door upper damper stay bracket. |

|

Disposal

DISPOSAL

PROCEDURE

1. DISPOSE OF BACK DOOR STAY ASSEMBLY

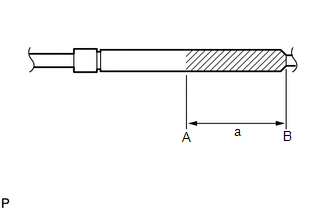

(a) Secure the back door stay assembly horizontally in a vise with the piston rod pulled out.

|

(b) Wear safety glasses. Use a metal saw to slowly cut a groove between A and B shown in the illustration to release the gas. Standard Dimension: a 80.0 mm (3.150 in.) NOTICE: Although the gas inside the back door stay assembly is colorless, odorless and harmless, metal debris may scatter. Therefore, cover the back door stay assembly with a piece of cloth or other material. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL BACK DOOR UPPER DAMPER STAY BRACKET

(a) Clean the threaded portion on the vehicle body with a non-residue solvent.

(b) Apply adhesive to the threads of the 2 bolts.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

|

(c) Install the back door upper damper stay bracket with the 2 bolts. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

2. INSTALL BACK DOOR LOWER DAMPER STAY BRACKET

(a) Clean the threaded portion on the vehicle body with a non-residue solvent.

(b) Apply adhesive to the threads of the 2 bolts.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

|

(c) Install the back door lower damper stay bracket with the 2 bolts. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

3. INSTALL BACK DOOR STAY ASSEMBLY

NOTICE:

- Avoid touching the piston rod as much as possible to prevent foreign matter from attaching to it. Be sure to hold the cylinder while servicing.

- Do not wear cotton gloves or other similar materials when handling the piston rod. Fibers may attach to the rod and result in gas leaks.

- Do not apply any horizontal load to the door stay in order to prevent the rod from deforming.

(a) When reusing the back door stay assembly:

|

(1) Install the 2 stop rings to the back door stay assembly. |

|

|

(b) Install the back door stay assembly. NOTICE: Install the back door stay assembly while supporting the back door by hand. |

|

(c) Check that the back door stay assembly is engaged in the ball joint and that the back door stay assembly cannot be pulled out.

Back Door Opener Switch

Back Door Opener Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

2. REMOVE REAR LIGHT ASSEMBLY LH

3. REMOVE REAR LIGHT ASSEMBLY RH

HINT:

Use t ...

Front Door

Front Door

...

Other materials about Toyota Venza:

Fuel Tank Cap

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL TANK CAP ASSEMBLY

(a) Visually check that the fuel tank cap assembly and gasket are not

deformed or damaged.

Text in Illustration

*a

Gasket

...

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

CAUTION:

Be sure to read Precaution thoroughly before servicing (See page

).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

bat ...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

0.1659

.png)

.png)