Toyota Venza: Back Door Courtesy Switch

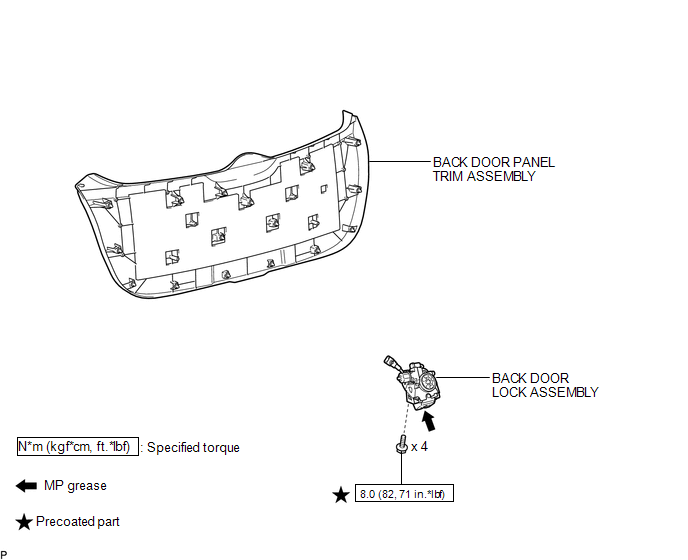

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

.gif)

2. REMOVE BACK DOOR LOCK ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Disengage the clamp.

(c) Remove the bolt.

|

(d) Remove the 3 bolts and back door lock assembly. |

|

Inspection

INSPECTION

PROCEDURE

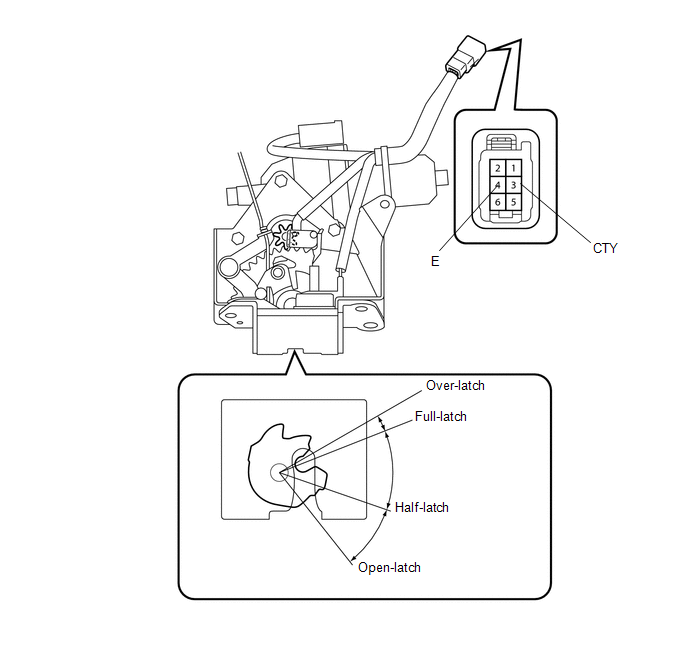

1. INSPECT BACK DOOR COURTESY SWITCH (BACK DOOR LOCK ASSEMBLY)

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 (CTY) - 4 (E) |

Open-latched |

Below 1 Ω |

|

3 (CTY) - 4 (E) |

Half-latched |

Below 1 Ω |

|

3 (CTY) - 4 (E) |

Full-latched |

10 kΩ or higher |

|

3 (CTY) - 4 (E) |

Over-latched |

10 kΩ or higher |

If the result is not specified, replace the back door lock assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL BACK DOOR LOCK ASSEMBLY

(a) Apply MP grease to the sliding parts of the back door lock assembly.

(b) Apply adhesive to the threads of the bolt.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

|

(c) Install the back door lock assembly with the 3 bolts. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

|

(d) Install the bolt. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

(e) Engage the clamp.

(f) Connect the connector.

2. INSTALL BACK DOOR PANEL TRIM ASSEMBLY

.gif)

Lighting (int)

Lighting (int)

...

Console Box Light

Console Box Light

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Hea ...

Other materials about Toyota Venza:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL ECM

(a) Install the bracket to the ECM with the 5 screws.

(b) Install the ECM with the 3 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

...

Calibration

CALIBRATION

1. DESCRIPTION

(a) Follow the chart below to perform calibration.

Parts to be Replaced

Necessary Operation

Brake actuator assembly (Skid control ECU)

Perform engine variant learning

2. ...

0.1604

.png)

.png)

.png)

.png)