Toyota Venza: Automatic Light Control Sensor

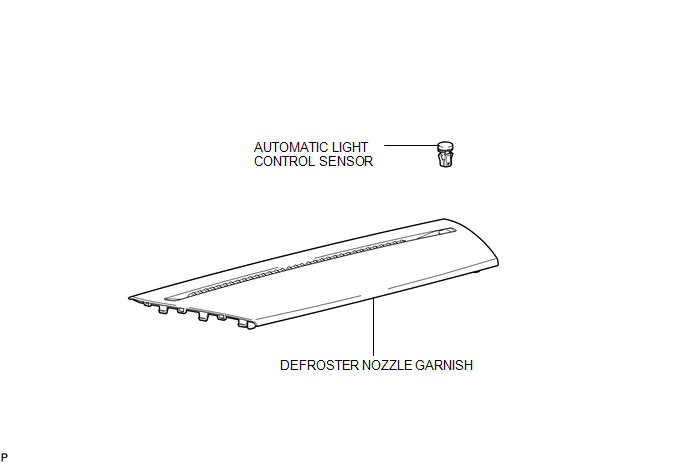

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE DEFROSTER NOZZLE GARNISH

.gif)

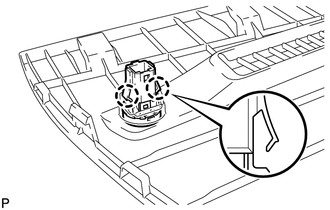

2. REMOVE AUTOMATIC LIGHT CONTROL SENSOR

|

(a) Disengage the 2 claws and remove the automatic light control sensor. |

|

Inspection

INSPECTION

PROCEDURE

1. INSPECT AUTOMATIC LIGHT CONTROL SENSOR

|

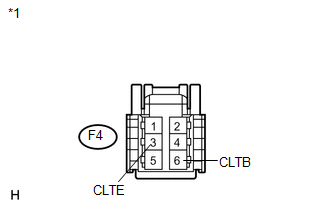

(a) Disconnect the F4 automatic light control sensor connector. |

|

(b) Measure the voltage and resistance according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F4-6 (CLTB) - F4-3 (CLTE) |

Ignition switch off |

Below 1 V |

|

Ignition switch ON |

10 to 14 V |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F4-3 (CLTE) - Body ground |

Always |

Below 1 Ω |

|

*1 |

Front view of wire harness connector (to Automatic Light Control Sensor) |

If the result is not as specified, there may be a malfunction on the wire harness side.

|

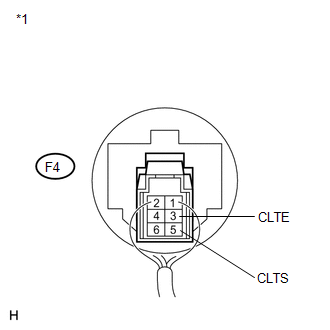

(c) Reconnect the F4 automatic light control sensor connector. |

|

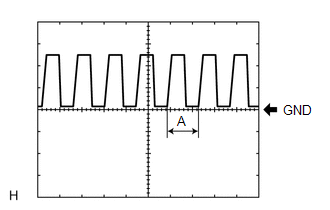

(d) Connect an oscilloscope to the automatic light control sensor connector.

Text in Illustration|

*1 |

Component with harness connected (Automatic Light Control Sensor) |

|

(e) Check the waveform. OK:

HINT: If the ambient light becomes brighter, width A becomes narrower. If the result is not as specified, replace the automatic light control sensor. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL AUTOMATIC LIGHT CONTROL SENSOR

|

(a) Engage the 2 claws to install the automatic light control sensor. |

|

2. INSTALL DEFROSTER NOZZLE GARNISH

.gif)

Afs Ecu

Afs Ecu

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL AFS ECU

(a) Engage the guide.

(b) Install the ...

Door Mirror Foot Light

Door Mirror Foot Light

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for both the RH and LH sides.

The procedure described below is for the ...

Other materials about Toyota Venza:

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. SEPARATE REAR FLEXIBLE HOSE

3. SEPARATE REAR DI ...

Front Left Sensor Malfunction (C1AE1)

DESCRIPTION

The No. 1 ultrasonic sensor (front left sensor) is installed on the front bumper.

The ECU detects obstacles based on signals received from the No. 1 ultrasonic sensor

(front left sensor). If the No. 1 ultrasonic sensor (front left sensor) has ...

Front Power Seat does not Operate with Front Power Seat Switch

DESCRIPTION

Signals are input into the position control ECU and switch assembly. The built-in

ECU manages the signals received from the position control ECU and switch assembly,

and operates each motor. If the position control ECU and switch assembly rece ...

0.1701

.png)