Toyota Venza: Washer Level Warning Switch

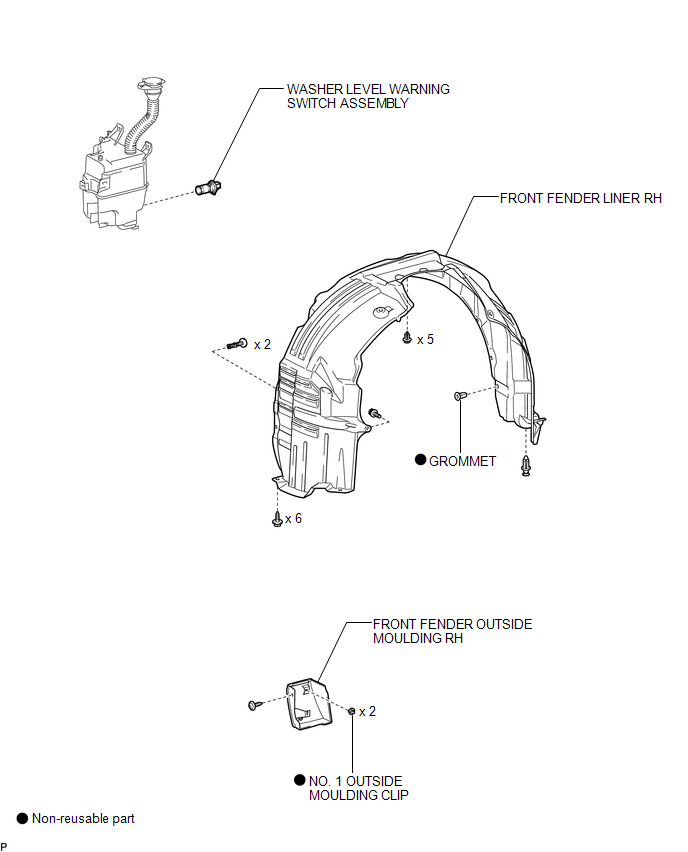

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

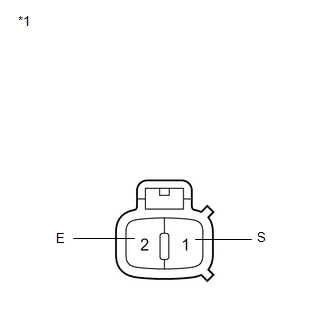

1. INSPECT LEVEL WARNING SWITCH ASSEMBLY

HINT:

The following check should be performed with the windshield washer motor and pump installed to the washer jar.

(a) Fill the washer jar with washer fluid.

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the level warning switch assembly. Text in Illustration

|

|

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER OUTSIDE MOULDING RH

HINT:

Use the same procedure for the RH side and LH side (See page

.gif) ).

).

3. REMOVE FRONT FENDER LINER RH

.gif)

4. DRAIN WINDSHIELD WASHER FLUID

.gif)

5. REMOVE WASHER LEVEL WARNING SWITCH ASSEMBLY

|

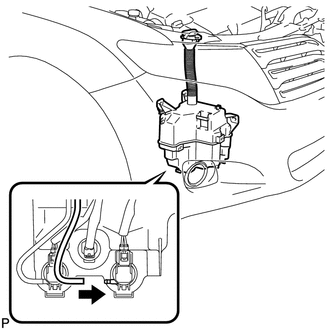

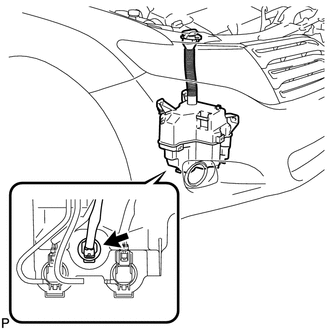

(a) Disconnect the connector. |

|

(b) Remove the washer level warning switch assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL WASHER LEVEL WARNING SWITCH ASSEMBLY

|

(a) Install the washer level warning switch assembly. |

|

(b) Connect the connector.

|

(c) Connect the washer hose. |

|

2. FILL WASHER JAR WITH WASHER FLUID

.gif)

3. INSTALL FRONT FENDER LINER RH

.gif)

4. INSTALL FRONT FENDER OUTSIDE MOULDING RH

HINT:

Use the same procedure for the RH side and LH side (See page

.gif) ).

).

5. INSTALL FRONT WHEEL RH

Rear Wiper Rubber

Rear Wiper Rubber

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE REAR WIPER BLADE

(a) Disconnect the rear wiper arm head cap.

...

Washer Motor(for Front Side)

Washer Motor(for Front Side)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER OUTSIDE MOULDING RH

HINT:

Use the same procedure for the RH side and LH side ...

Other materials about Toyota Venza:

Washer Motor(for Front Side)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER OUTSIDE MOULDING RH

HINT:

Use the same procedure for the RH side and LH side (See page

).

3. REMOVE FRONT FENDER LINER RH

...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure listed to troubleshoot the Active Torque

Control 4WD system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

...

Air Fuel Ratio Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

2. REMOVE COOL AIR INTAKE DUCT SEAL

3. REMOVE INLET AIR CLEANER ASSEMBLY

4. REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

5. REMOV ...

0.1158

.png)