Toyota Venza: Adjustment

ADJUSTMENT

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

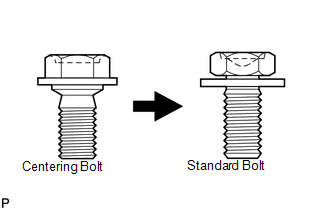

- Centering bolts are used to mount the door hinge to the vehicle body and door. The door cannot be adjusted with the centering bolts installed. Substitute the centering bolts with standard bolts (with washers) when making adjustments.

- Specified torque for standard bolts is shown in the standard bolt chart

(See page

.gif) ).

).

PROCEDURE

1. INSPECT BACK DOOR

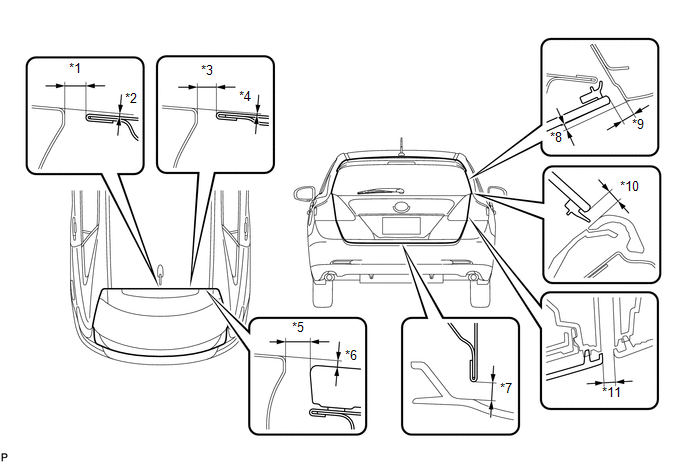

(a) Check that the clearance measurements of areas *1 through *11 are within each standard range.

Standard Clearance

Standard Clearance

|

Area |

Measurement |

Area |

Measurement |

|---|---|---|---|

|

*1 |

6.3 to 9.3 mm (0.248 to 0.366 in.) |

*7 |

5.1 to 8.1 mm (0.201 to 0.319 in.) |

|

*2 |

0 to 3.0 mm (0 to 0.118 in.) |

*8 |

0.3 to 4.3 mm (0.0118 to 0.169 in.) |

|

*3 |

6.3 to 9.3 mm (0.248 to 0.366 in.) |

*9 |

4.0 to 7.0 mm (0.157 to 0.276 in.) |

|

*4 |

0.1 to 3.1 mm (0.00394 to 0.122 in.) |

*10 |

3.7 to 6.7 mm (0.146 to 0.264 in.) |

|

*5 |

6.6 to 9.6 mm (0.260 to 0.378 in.) |

*11 |

3.7 to 6.7 mm (0.146 to 0.264 in.) |

|

*6 |

0.1 to 3.1 mm (0.00394 to 0.122 in.) |

- |

- |

2. REMOVE REAR FLOOR FINISH PLATE

.gif)

3. ADJUST BACK DOOR PANEL SUB-ASSEMBLY

|

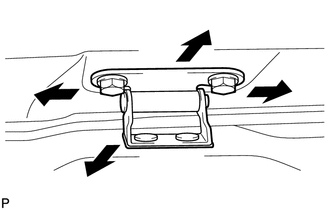

(a) Before adjusting the upper end of the back door up and down or left and right, loosen the bolts. |

|

(b) Tighten the body side hinge after the adjustment.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

|

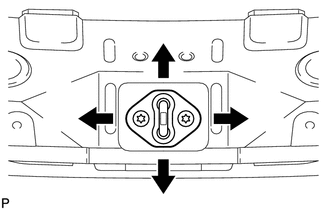

(c) Using a T40 "TORX" socket wrench, slightly loosen the striker mounting screws. |

|

(d) Using a brass bar and a hammer, hit the striker to adjust its position.

(e) Using a T40 "TORX" socket wrench, tighten the striker mounting screws after the adjustment.

Torque:

23 N·m {235 kgf·cm, 17 ft·lbf}

4. INSTALL REAR FLOOR FINISH PLATE

.gif)

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE UPPER BACK WINDOW PANEL TRIM

(a) Disengage the 4 clips and 4 claws, and remove the upper back window

panel trim.

...

Other materials about Toyota Venza:

Fail-safe Chart

FAIL-SAFE CHART

If a problem occurs in the power steering system, the power steering assist will

be stopped or the amount of power assist will be decreased to protect the system.

Power Steering System

Malfunction

Fail-safe Operation

...

Short to GND in Immobiliser System Power Source Circuit (B278A)

DESCRIPTION

This DTC is stored when the engine switch power source supply line is open or

shorted.

DTC No.

DTC Detection Condition

Trouble Area

B278A

Engine switch power source supply line is ope ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT REAR STABILIZER LINK ASSEMBLY

(a) Move the ball joint stud back and forth 5 times before installing

the nut as shown in the illustration.

(b) Using a torque wrenc ...

0.1732