Toyota Venza: ACC Monitor Malfunction (B2274)

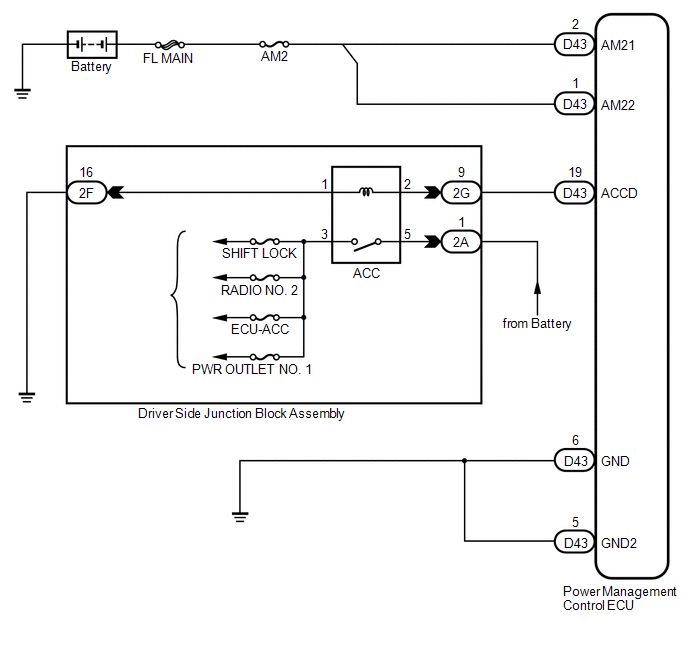

DESCRIPTION

This DTC is stored when there is a problem in the ACC output circuit. The ACC circuit is the circuit that goes from inside the power management control ECU to the ACC relay.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B2274 |

The ACC relay actuation circuit inside the power management control ECU or other related circuit is malfunctioning. |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When the power management control ECU is replaced with a new one and the cable from the negative (-) battery terminal is connected, the power source mode becomes the on (IG) mode. When the battery is removed and reinstalled, the power source mode that was selected when the battery was removed is restored.

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU) |

.gif)

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU) |

|

|

2. |

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

.gif)

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

|

|

3. |

CHECK HARNESS AND CONNECTOR |

(a) Disconnect the 2G connector from the main body ECU (driver side junction block assembly).

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

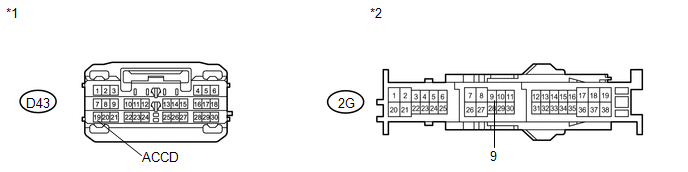

D43-19 (ACCD) - 2G-9 |

Always |

Below 1 Ω |

|

D43-19 (ACCD) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Power Management Control ECU) |

*2 |

Front view of wire harness connectors (to Main Body ECU (Driver Side Junction Block Assembly)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR |

.gif)

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

INSPECT ACC RELAY |

|

(a) Remove the ACC relay from the main body ECU (driver side junction block assembly). |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

Always |

93.8 to 136.4 Ω |

|

3 - 5 |

When battery voltage is not applied to terminals 1 and 2 |

10 kΩ or higher |

|

3 - 5 |

When battery voltage is applied to terminals 1 and 2 |

Below 1 Ω |

| NG | .gif) |

REPLACE ACC RELAY |

|

|

6. |

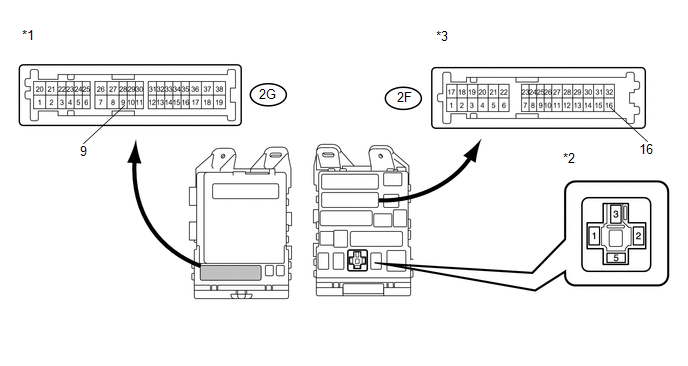

INSPECT MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

(a) Remove the main body ECU (driver side junction block assembly) (See page

.gif) ).

).

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2G-9 - ACC relay terminal 2 |

Always |

Below 1 Ω |

|

2G-9 - Body ground |

Always |

10 kΩ or higher |

|

2F-16 - ACC relay terminal 1 |

Always |

Below 1 Ω |

|

2F-16 - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

*3 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

|

*2 |

Component without relay connected (ACC Relay Terminal) |

- |

- |

| OK | .gif) |

REPLACE POWER MANAGEMENT CONTROL ECU |

| NG | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

Brake Signal Malfunction (B2284)

Brake Signal Malfunction (B2284)

DESCRIPTION

The power management control ECU receives brake signal information from 2 sources.

It receives a signal from the stop light switch assembly via a direct line, and

a signal from the EC ...

Engine does not Start

Engine does not Start

DESCRIPTION

1. ENGINE START SYSTEM FUNCTION

(a) If the engine switch is pressed with the shift lever in P or N and the brake

pedal depressed, the power management control ECU determines that this ...

Other materials about Toyota Venza:

Noise Occurs

PROCEDURE

1.

CHECK NOISE CONDITION

(a) Check from which direction the noise comes (front left or right, or rear

left or right).

OK:

The location of the noise source can be determined.

NG

GO TO STEP 3

...

Definition Of Terms

DEFINITION OF TERMS

Term

Definition

Monitor description

Description of what the TCM monitors and how it detects malfunctions

(monitoring purpose and its details).

Related DTCs

D ...

Calibration

CALIBRATION

1. ROTATION ANGLE SENSOR INITIALIZATION AND TORQUE SENSOR ZERO POINT CALIBRATION

NOTICE:

Clear the rotation angle sensor calibration value, initialize the rotation angle

sensor, and calibrate the torque sensor zero point if any of the followin ...

0.163

.gif)

.png)