Toyota Venza: Speedometer Malfunction

DESCRIPTION

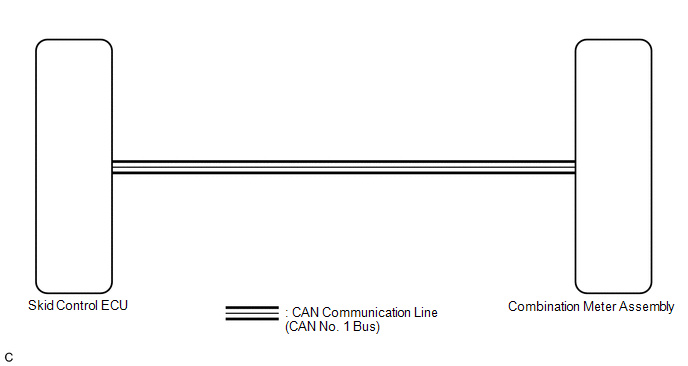

The meter CPU receives vehicle speed signals from the skid control ECU via the CAN communication system (CAN No. 1 Bus). The speed sensor detects the wheel speed and sends the appropriate signals to the skid control ECU. The skid control ECU supplies power to the vehicle speed sensor. The skid control ECU detects vehicle speed signals based on the pulses of the voltage.

HINT:

- Factors that affect the indicated vehicle speed include tire size, tire

inflation, and tire wear. The speed indicated on the speedometer has an

allowable margin of error. This can be tested using a speedometer tester

(calibrated chassis dynamometer). For details about testing and the margin

of error, see the reference chart (See page

.gif) ).

). - If the vehicle speed sensor circuit has a malfunction, the skid control

ECU outputs the DTCs. Refer to troubleshoot Brake Control System (See page

.gif) ).

).

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the vehicle speed is outside the allowable range when tested, perform the

following procedure (See page .gif) ).

).

HINT:

Before starting the following inspection, check tire size and tire air pressure.

PROCEDURE

|

1. |

CHECK CAN COMMUNICATION SYSTEM |

(a) Check if a CAN communication DTC is output (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

CAN communication DTC is not output. |

A |

|

CAN communication DTC is output. |

B |

| B | .gif) |

GO TO CAN COMMUNICATION SYSTEM |

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM (SPEED METER OPERATION) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Combination Meter / Active Test.

(e) Check the operation by referring to the table below.

Combination Meter|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Speed Meter Operation |

Speedometer |

0, 40, 80, 120, 160, 200, 240 km/h |

Confirm that the vehicle is stopped with the engine idling |

|

Acceptable range (km/h): [Control range → Speedometer display]

|

OK:

Speedometer indication is normal.

| NG | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

|

|

3. |

READ VALUE USING TECHSTREAM (VEHICLE SPEED METER) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Combination Meter / Data List.

(e) Check the values by referring to the table below.

Combination Meter|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Vehicle Speed Meter |

Vehicle speed/Min.: 0 km/h (0 mph), Max.: 255 km/h (158 mph) |

Almost the same as actual vehicle speed (Speedometer tester) |

- |

OK:

Vehicle speed displayed on the Techstream is almost the same as the actual vehicle speed measured using a speedometer tester (calibrated chassis dynamometer).

| OK | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

|

|

4. |

READ VALUE USING TECHSTREAM (FR/FL/RR/RL WHEEL SPEED) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Chassis / ABS/VSC/TRAC / Data List.

(e) Check the values by referring to the table below.

ABS/VSC/TRAC|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

FR Wheel Speed |

Vehicle speed/Min.: 0 mph (0 km/h), Max.: 202 mph (326 km/h) |

Almost the same as actual vehicle speed (Speedometer tester) |

- |

|

FL Wheel Speed |

Vehicle speed/Min.: 0 mph (0 km/h), Max.: 202 mph (326 km/h) |

Almost the same as actual vehicle speed (Speedometer tester) |

- |

|

RR Wheel Speed |

Vehicle speed/Min.: 0 mph (0 km/h), Max.: 202 mph (326 km/h) |

Almost the same as actual vehicle speed (Speedometer tester) |

- |

|

RL Wheel Speed |

Vehicle speed/Min.: 0 mph (0 km/h), Max.: 202 mph (326 km/h) |

Almost the same as actual vehicle speed (Speedometer tester) |

- |

OK:

Vehicle speed displayed on the Techstream is almost the same as the actual vehicle speed measured using a speedometer tester (calibrated chassis dynamometer).

| NG | .gif) |

GO TO BRAKE CONTROL SYSTEM |

|

|

5. |

REPLACE SKID CONTROL ECU |

(a) Replace the skid control ECU with a new or a known good one (See page

.gif) ).

).

OK:

The operation of the speedometer returns to normal.

| OK | .gif) |

END |

| NG | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

Entire Combination Meter does not Operate

Entire Combination Meter does not Operate

DESCRIPTION

This circuit is the power source circuit for the meter. This circuit provides

two types of power sources; one is a constant power source mainly used as a backup

power source, and the ...

Tachometer Malfunction

Tachometer Malfunction

DESCRIPTION

In this circuit, the meter CPU receives engine speed signals from the ECM using

the CAN communication system (CAN No. 1 Bus). The meter CPU displays the engine

speed calculated based ...

Other materials about Toyota Venza:

Seat belts

Make sure that all occupants are wearing their seat belts before driving the

vehicle.

- Correct use of the seat belts

1. Extend the shoulder belt so that it comes fully over the shoulder, but does

not come into contact with the neck or slide off ...

System Diagram

SYSTEM DIAGRAM

Communication Table

Transmitting ECU (Transmitter)

Receiving ECU (Receiver)

Signal

Communication Method

Certification ECU (smart key ECU assembly)

Power management contro ...

Initialization

INITIALIZATION

1. RESET BACK DOOR CLOSE POSITION

NOTICE:

Perform initialization of the power back door system (power back door ECU initialization)

if one of the following is performed:

The cable is disconnected from the negative (-) battery termin ...

0.1675

.gif)