Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT COOLING FAN MOTOR

|

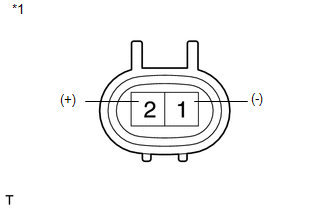

(a) Check that the motor operates smoothly when the battery is connected to the cooling fan motor connector. Text in Illustration

If the motor does not operate smoothly, replace the cooling fan motor. |

|

(b) Connect the pickup of a clamp-on ammeter over one of the 2 wires for the cooling fan motor.

(c) Measure the current while the motor is operating.

Standard Current:

|

Item |

Condition |

Specified Condition |

|---|---|---|

|

Cooling fan motor (w/o Towing package) |

20°C (68°F) |

11.8 to 14.8 A at 12 V |

|

Cooling fan motor (w/ Towing package) |

20°C (68°F) |

7.9 to 10.9 A at 12 V |

If the result is not as specified, replace the cooling fan motor.

2. INSPECT NO. 2 COOLING FAN MOTOR

|

(a) Check that the motor operates smoothly when the battery is connected to the No. 2 cooling fan motor connector. Text in Illustration

If the motor does not operate smoothly, replace the No. 2 cooling fan motor. |

|

(b) Connect the pickup of a clamp-on ammeter over one of the 2 wires for the No. 2 cooling fan motor.

(c) Measure the current while the motor is operating.

Standard Current:

|

Item |

Condition |

Specified Condition |

|---|---|---|

|

No. 2 cooling fan motor (w/o Towing package) |

20°C (68°F) |

7.9 to 10.9 A at 12 V |

|

No. 2 cooling fan motor (w/ Towing package) |

20°C (68°F) |

7.9 to 10.9 A at 12 V |

If the result is not as specified, replace the No. 2 cooling fan motor.

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE RADIATOR ASSEMBLY AND FAN ASSEMBLY WITH MOTOR

HINT:

See page

2. REMOVE FAN

(a) Remove the nut and fan.

3. ...

Other materials about Toyota Venza:

USB Device Malfunction (B1585)

DESCRIPTION

This DTC is stored when a malfunction occurs in a connected device.

DTC No.

DTC Detection Condition

Trouble Area

B1585

When any of the following conditions is met:

A non m ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 14 ROOF SILENCER PAD

(a) Align the markings on the roof headlining assembly with the No. 14 roof silencer

pad and install the silencer pad using hot-melt glue as shown in the illustration.

2. INSTALL NO. 1 ROOF WIRE ...

Engine Stall History (P1603,P1605)

DESCRIPTION

P1603

After starting the engine, this DTC is stored when the engine stops without the

ignition switch being operated.

Using the Techstream, the conditions present when the DTC was stored can be confirmed

by referring to the freeze frame data ...

0.1304