Toyota Venza: Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Release the vacuum from the booster by depressing the brake pedal several times. Then remove the brake master cylinder from the brake booster.

PROCEDURE

1. REMOVE FRONT WIPER ARM HEAD CAP

2. REMOVE FRONT WIPER ARM AND BLADE ASSEMBLY LH

.gif)

3. REMOVE FRONT WIPER ARM AND BLADE ASSEMBLY RH

.gif)

4. REMOVE FRONT FENDER TO COWL SIDE SEAL LH

.gif)

5. REMOVE FRONT FENDER TO COWL SIDE SEAL RH

.gif)

6. REMOVE COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

.gif)

7. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

.gif)

8. REMOVE OUTER COWL TOP PANEL

.gif)

9. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (for 1AR-FE)

.gif)

10. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (for 2GR-FE)

.gif)

11. REMOVE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

12. REMOVE AIR CLEANER CASE (for 1AR-FE)

.gif)

13. REMOVE AIR CLEANER CASE (for 2GR-FE)

.gif)

14. REMOVE SECURITY HORN ASSEMBLY (w/ Security Horn)

.gif)

15. REMOVE BRAKE MASTER CYLINDER SUB-ASSEMBLY

.gif)

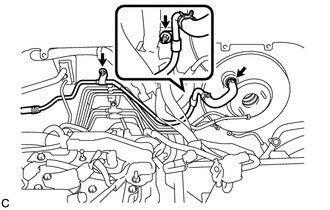

16. SEPARATE NO. 1 VACUUM HOSE CONNECTOR (for 1AR-FE)

|

(a) Slide the clip and disconnect the vacuum hose from the brake booster assembly. |

|

(b) Remove the 2 nuts and separate the No. 1 vacuum hose connector.

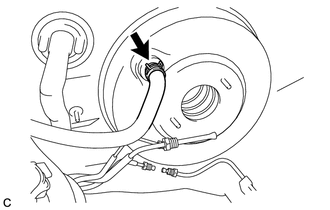

17. DISCONNECT VACUUM HOSE (for 2GR-FE)

|

(a) Slide the clip and disconnect the vacuum hose from the brake booster assembly. |

|

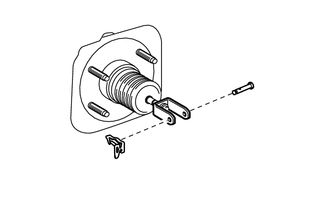

18. REMOVE PUSH ROD PIN

|

(a) Remove the clip and push rod pin. |

|

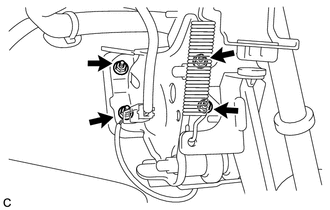

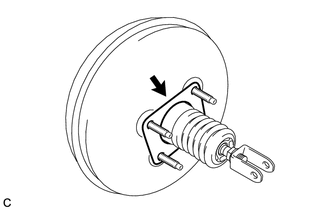

19. REMOVE BRAKE BOOSTER ASSEMBLY

|

(a) Remove the 4 nuts and brake booster assembly from the body. NOTICE: Do not damage the brake lines. |

|

20. REMOVE BRAKE BOOSTER GASKET

|

(a) Remove the brake booster gasket from the brake booster assembly. |

|

21. REMOVE BRAKE MASTER CYLINDER PUSH ROD CLEVIS

(a) Loosen the lock nut, and remove the brake master cylinder push rod clevis and lock nut.

22. REMOVE BRAKE VACUUM CHECK VALVE ASSEMBLY

(a) Remove the brake vacuum check valve assembly from the brake booster assembly.

23. REMOVE CHECK VALVE GROMMET

(a) Remove the check valve grommet from the brake booster assembly.

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT BRAKE BOOSTER ASSEMBLY

(a) Airtightness check

(1) Start the engine and stop it after 1 or 2 minutes. Slowly depress

the brake pedal seve ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT BRAKE VACUUM CHECK VALVE ASSEMBLY

(a) Check that there is ventilation from the booster to the engine, and

no ventilation from the engine to the booste ...

Other materials about Toyota Venza:

Receiver Error (C2176/76)

DESCRIPTION

The signals are transmitted to the tire pressure warning antenna and receiver

on the body as radio waves and then sent to the tire pressure warning ECU.

DTC No.

DTC Detection Condition

Trouble Area

...

Operation Check

OPERATION CHECK

1. CHECK REMOTE CONTROL MIRROR FUNCTION

(a) Turn the ignition switch ON.

(b) With the mirror select switch set to L, check that the outer rear view mirror

LH surface moves up, down, left and right normally.

(c) With the mirror select swit ...

Door Side Airbag Sensor RH Malfunction (B1690/15)

DESCRIPTION

The side collision sensor RH circuit (to determine deployment of the front seat

side airbag assembly RH and curtain shield airbag assembly RH) is composed of the

center airbag sensor assembly, rear airbag sensor RH and side airbag sensor RH.

...

0.1342