Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT BRAKE BOOSTER ASSEMBLY

|

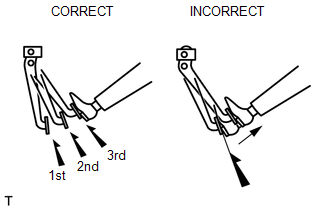

(a) Airtightness check (1) Start the engine and stop it after 1 or 2 minutes. Slowly depress the brake pedal several times. HINT: If the pedal can be depressed to the floor the first time, but on the 2nd and 3rd time cannot be depressed as far, the booster is airtight. (2) Depress the brake pedal while the engine is running, and stop the engine with the pedal depressed. HINT: If there is no change in the pedal reserve distance while holding the pedal depressed for 30 seconds, the booster is airtight. |

|

(b) Operation check

|

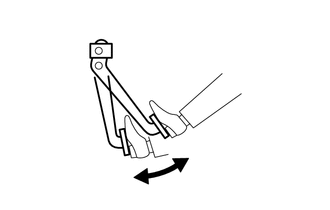

(1) Depress the brake pedal several times with the ignition switch off and check that there is no change in the pedal reserve distance when the pedal is depressed. |

|

|

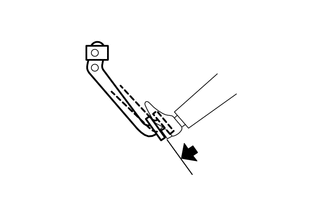

(2) Depress and hold the brake pedal, then start the engine. HINT: If the pedal goes down slightly, operation is normal. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Release the vacuum from the booster by depressing the brake pedal several times.

Then remove the brake master cylinder from the brake booster.

PROCEDURE

...

Other materials about Toyota Venza:

Front seats

► Power seat

1. Seat position fore/aft control switch

2. Seatback angle control switch

3. Seat cushion (front) angle control switch (driver’s side only)

4. Vertical height control switch (driver’s side only)

5. Lumbar support control switch

& ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE FRONT TRANSAXLE CASE OIL SEAL

(a) Using SST, remove the front transaxle case oil seal from the transaxle

housing.

SST: 09308-00010

2. REMOVE TRANSAXLE CASE OIL ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. REMOVE DECK SIDE TRIM

(a) Disengage the 5 claws, and ...

0.1391