Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

.gif)

3. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Heater System)

.gif)

4. REMOVE NO. 2 CONSOLE BOX CARPET

.gif)

5. REMOVE CONSOLE BOX ASSEMBLY

.gif)

6. REMOVE AIR CONDITIONING CONTROL ASSEMBLY

.gif)

7. REMOVE FRONT DOOR SCUFF PLATE LH

.gif)

8. REMOVE COWL SIDE TRIM SUB-ASSEMBLY LH

.gif)

9. REMOVE LOWER NO. 1 INSTRUMENT PANEL FINISH PANEL

.gif)

10. REMOVE FRONT DOOR SCUFF PLATE RH

.gif)

11. REMOVE COWL SIDE TRIM SUB-ASSEMBLY RH

.gif)

12. REMOVE NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

13. REMOVE LOWER INSTRUMENT PANEL SUB-ASSEMBLY

.gif)

14. REMOVE SHIFT LEVER KNOB SUB-ASSEMBLY

.gif)

15. REMOVE CONSOLE BOX SUB-ASSEMBLY

.gif)

16. REMOVE LOWER STEERING COLUMN COVER

.gif)

17. REMOVE UPPER STEERING COLUMN COVER

.gif)

18. REMOVE INSTRUMENT CLUSTER FINISH PANEL

.gif)

19. REMOVE LOWER INSTRUMENT PANEL FINISH PANEL ASSEMBLY

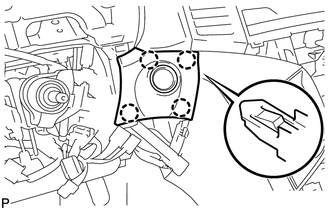

|

(a) Disengage the 4 claws. |

|

(b) Disconnect the connector and remove the lower instrument panel finish panel assembly.

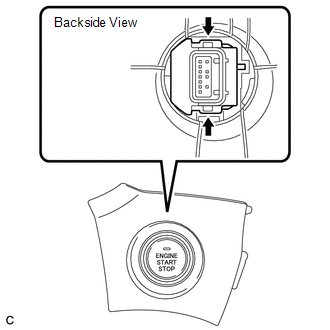

20. REMOVE ENGINE SWITCH

|

(a) Detach the 2 claws and remove the engine switch. |

|

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT ENGINE SWITCH

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Switch Condi ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE SWITCH

(a) Attach the 2 claws to install the engine switch.

2. INSTALL LOWER INSTRUMENT PANEL FI ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 3 ANTENNA CORD SUB-ASSEMBLY

(a) Pass the washer hose through the No. 3 antenna cord sub-assembly.

(b) Pass the No. 3 antenna cord sub-assembly with washer hose through

the vehicle body as shown in the il ...

No Sound can be Heard from Speakers

PROCEDURE

1.

CHECK AUDIO SETTINGS

(a) In sound output setting mode, set volume, fader and balance to the initial

values and check that the sound is normal.

OK:

Audio system returns to normal.

HINT:

Sound quality adjustm ...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Front power seat control system (w/ Memory) data and Diagnostic Trouble Codes

(DTCs) can be read through the Data Link Connector 3 (DLC3) of the vehicle. When

the system seems to be malfunctioning, use the Techstream t ...

0.113