Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT ENGINE SWITCH

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

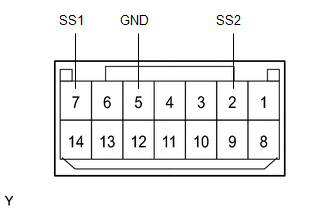

7 (SS1) - 5 (GND) |

Not pushed |

10 kΩ or higher |

|

2 (SS2) - 5 (GND) |

Not pushed |

10 kΩ or higher |

|

7 (SS1) - 5 (GND) |

Pushed |

15 Ω |

|

2 (SS2) - 5 (GND) |

Pushed |

15 Ω |

If the result is not as specified, replace the engine switch.

(b) Apply battery voltage between the terminals of the switch, and check the illumination condition of the engine switch.

HINT:

- If a positive (+) battery lead and a negative (-) battery lead are incorrectly connected, the engine switch indicator light will not illuminate.

- If the voltage is too low, the indicator light will not illuminate.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

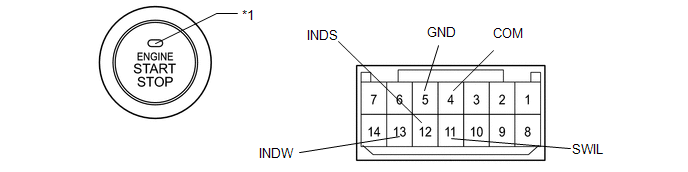

Battery positive (+) → Terminal 11 (SWIL) Battery negative (-) → Terminal 4 (COM) or 5 (GND) |

Illuminates |

|

Battery positive (+) → Terminal 12 (INDS) Battery negative (-) → Terminal 4 (COM) or 5 (GND) |

Illuminates |

|

Battery positive (+) → Terminal 13 (INDW) Battery negative (-) → Terminal 4 (COM) or 5 (GND) |

Illuminates |

Text in Illustration

Text in Illustration

|

*1 |

Indicator Light |

If the result is not as specified, replace the engine switch.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. RE ...

Other materials about Toyota Venza:

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT SEAT FRAME WITH ADJUSTER LH

(a) Check operation of the seat frame (slide motor).

(1) w/ Memory:

Check if the seat frame moves smoothly when the battery is connected

to the slide motor connector termin ...

Touch Panel Switch does not Function

PROCEDURE

1.

CHECK MULTI-DISPLAY

(a) Check if there is any foreign matter caught between the display and exterior

frame of the multi-display.

OK:

No foreign matter is caught between the display and exterior frame of the m ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 2 STEERING RACK BOOT

(a) Apply lithium soap base glycol grease to the inside of the small

opening of a new No. 2 steering rack boot.

(b) Install the No. 2 ste ...

0.1427