Toyota Venza: Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the fuel injector assembly

(See page .gif) ).

).

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

(a) Discharge fuel system pressure (See page

.gif) ).

).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

3. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

(a) Remove the windshield wiper motor and link assembly (See page

.gif) ).

).

4. REMOVE OUTER COWL TOP PANEL

.gif)

5. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

6. REMOVE NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

.gif)

7. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

.gif)

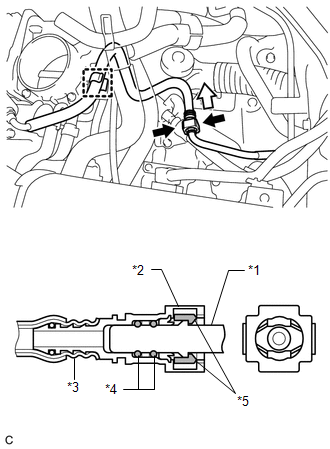

8. DISCONNECT FUEL TUBE SUB-ASSEMBLY

(a) Remove the No. 1 fuel pipe clamp.

(b) Pinch the retainer of the fuel tube connector, and then pull the fuel tube connector off of the fuel pipe.

Text in Illustration

Text in Illustration

|

*1 |

Fuel Pipe |

|

*2 |

Fuel Tube Connector |

|

*3 |

Nylon Tube |

|

*4 |

O-ring |

|

*5 |

Retainer |

.png) |

Pinch |

.png) |

Pull |

NOTICE:

- Check for foreign matter on the fuel tube around the fuel tube connector. Clean it if necessary. Foreign matter can affect the ability of the O-ring to seal the fuel tube connector and fuel pipe.

- Do not use any tools to separate the fuel tube connector and fuel pipe.

- Do not forcibly bend, kink or twist the nylon tube.

- Keep the connector and pipe free from foreign matter.

- If the fuel tube connector and fuel pipe are stuck, push and pull to release them.

- Cover the fuel tube connector and fuel pipe with plastic bags to prevent damage and contamination.

(c) Remove the fuel tube sub-assembly from the fuel hose clamp.

9. REMOVE VACUUM SWITCHING VALVE ASSEMBLY (for ACIS)

.gif)

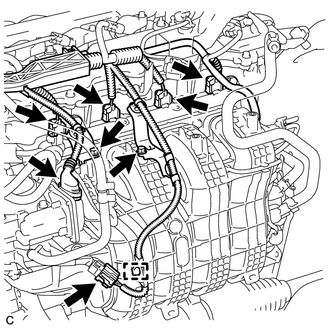

10. DISCONNECT WIRE HARNESS

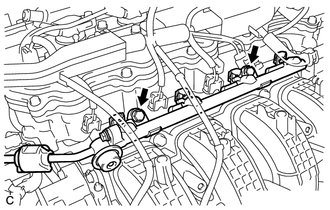

(a) Disconnect the 4 fuel injector connectors.

(b) Disconnect the 2 connectors.

(c) Remove the 2 bolts and separate the 2 wire harness brackets.

(d) Disengage the clamp to disconnect the wire harness.

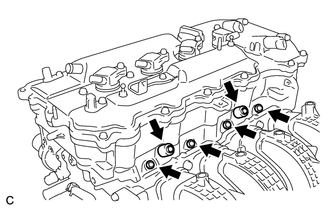

11. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

|

(a) Remove the 2 bolts, and then remove the fuel delivery pipe together with the 4 fuel injectors. NOTICE: Be careful not to drop the fuel injectors when removing the fuel delivery pipe. |

|

|

(b) Remove the 2 fuel delivery spacers from the cylinder head. |

|

(c) Remove the 4 injector vibration insulators from the cylinder head.

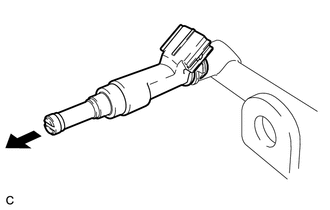

12. REMOVE FUEL INJECTOR ASSEMBLY

|

(a) Pull the 4 fuel injectors out of the fuel delivery pipe. |

|

(b) Remove the O-ring from each fuel injector.

(c) For reinstallation, attach a tag or label to each injector shaft.

NOTICE:

Prevent entry of foreign matter by covering the fuel injectors with plastic bags.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL INJECTOR ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connec ...

Other materials about Toyota Venza:

Door Control Transmitter(w/ Smart Key System)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE TRANSMITTER BATTERY

Inspection

INSPECTION

PROCEDURE

1. INSPECT DOOR CONTROL TRANSMITTER

(a) Inspect operation of the transmitter.

(1) Remove the battery (lithium batt ...

Lost Communication with Clearance Warning ECU (U1110)

DESCRIPTION

DTC Code

DTC Detection Condition

Trouble Area

U1110

No communication from the clearance warning ECU assembly continues.

Clearance warning ECU assembly branch wire o ...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) When troubleshooting a vehicle with a diagnosis system, the only difference

from the usual troubleshooting procedure is connecting the Techstream to the vehicle

and reading various data output from the clearance warnin ...

0.1147