Toyota Venza: Speed Sensor(when Not Using The Engine Support Bridge)

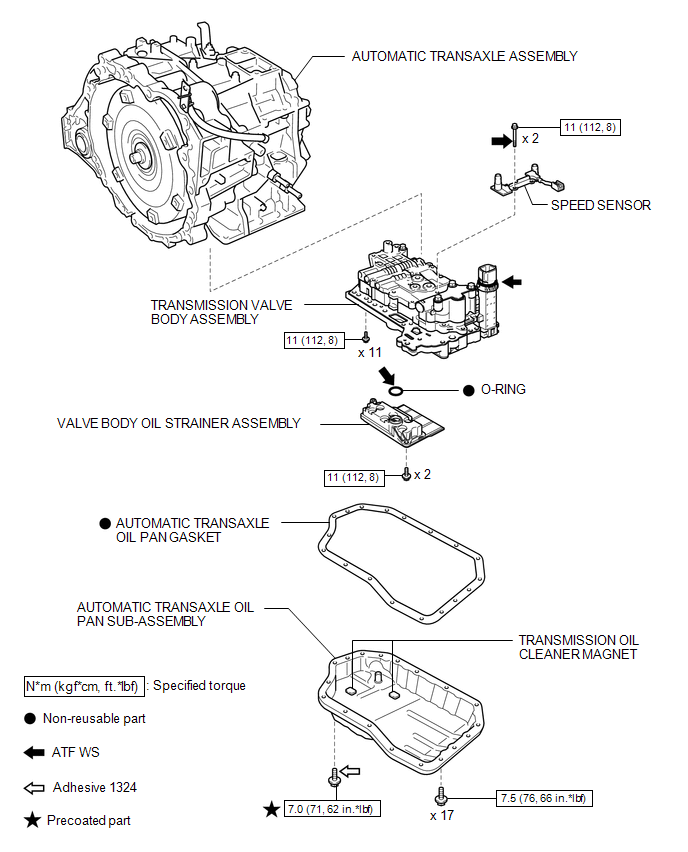

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

HINT:

See the steps from "Remove Engine Assembly with transaxle" through "Remove Automatic

Transaxle Assembly" (See page .gif) ).

).

2. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY

.gif)

3. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

.gif)

4. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

.gif)

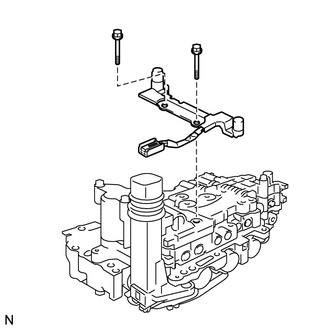

5. REMOVE SPEED SENSOR

(a) Disconnect the speed sensor connector.

|

(b) Remove the 2 bolts and speed sensor from the transmission valve body assembly. |

|

Installation

INSTALLATION

PROCEDURE

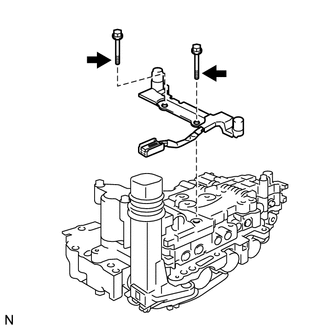

1. INSTALL SPEED SENSOR

|

(a) Coat the 2 bolts with ATF. |

|

(b) Install the speed sensor to the transmission valve body assembly with the 2 bolts.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

(c) Connect the speed sensor connector.

2. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

.gif)

3. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

.gif)

4. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY

.gif)

5. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

HINT:

See the steps from "Install Automatic Transaxle Assembly" through "Install Engine

Assembly with Transaxle" (See page .gif) ).

).

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL SHIFT LOCK CONTROL COMPUTER SUB-ASSEMBLY

(a) Engage the 3 claws to install the shift lock control computer sub-assembly.

...

Speed Sensor(when Using The Engine Support Bridge)

Speed Sensor(when Using The Engine Support Bridge)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

See page

2. REMOVE SPEED SENSOR

(a) Disconnect the speed sensor connector.

...

Other materials about Toyota Venza:

Emission Control System

Parts Location

PARTS LOCATION

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FUEL CUT-OFF RPM

(a) Increase the engine speed to at least 3500 rpm.

(b) Use a sound scope to check for injector operating soun ...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE COOL AIR INTAKE DUCT SEAL

3. REMOVE NO. 1 ENGINE CO ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 1 CENTER SUPPORT BEARING ASSEMBLY

(a) Set the No. 1 center support bearing on the intermediate shaft as

shown in the illustration.

NOTICE:

Make sure to install the bearing in the correct position.

...

0.1732