Toyota Venza: Inspection

INSPECTION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the intake side and exhaust side.

PROCEDURE

1. INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

|

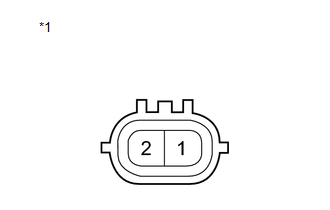

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the oil control valve assembly. Text in Illustration

|

|

|

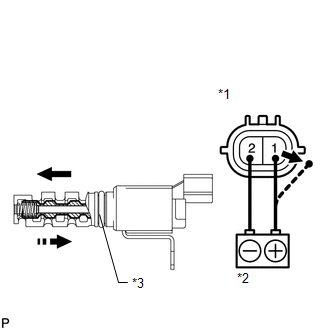

(b) Connect the positive (+) lead from a battery to terminal 1 and the negative (-) lead to terminal 2, and check the movement of the valve. OK:

NOTICE: Confirm that the valve moves freely and does not stick in any position. If necessary, replace the camshaft timing oil control valve assembly. HINT: Accumulation of foreign matter can cause minor pressure leaks. Minor pressure leaks will cause the camshaft to advance or retard, and this will cause a DTC to be set. Text in Illustration

|

|

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

2. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Exhaust Side)

(a) Disconnect the oil control valve connector.

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Exhaust Side)

(a) Apply a light coat of engine oil to a new O-ring, and install it

to the oil contro ...

Other materials about Toyota Venza:

GCWR, TWR and Unbraked TWR

Confirm that the gross trailer weight, gross combination weight, gross vehicle

weight, gross axle weight and tongue weight are all within the limits.

- GCWR* and TWR*

► Vehicles without towing package

► Vehicles with towing package

...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

NOTICE:

After replacing the stereo component tuner assembly of vehicles subscribed to

pay-type satellite radio broadcasts, XM radio ID registration is necessary (w/ SDARS

System).

HINT:

Use the table below to help determi ...

Camshaft Position "B" - Timing Over-Advanced or System Performance (Bank 1)

(P0014,P0015)

DESCRIPTION

Refer to DTC P0013 (See page ).

DTC No.

DTC Detection Condition

Trouble Area

P0014

The valve timing is stuck at a certain value when in the advance range

(2 trip detection logic).

...

0.1185