Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL PUMP ASSEMBLY WITH FILTER

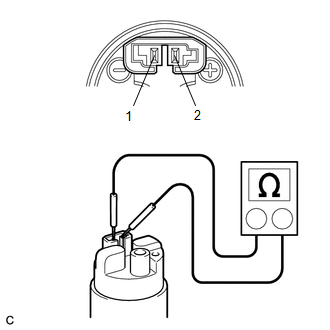

(a) Inspect fuel pump resistance.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

20°C (68°F) |

0.2 to 3.0 Ω |

If the result is not as specified, replace the fuel pump.

(b) Inspect fuel pump operation.

(1) Connect a battery positive (+) lead to terminal 2 of the connector, and a negative (-) lead to terminal 1. Check that the fuel pump operates.

NOTICE:

- These tests must be performed within 10 seconds to prevent the coil from burning out.

- Keep the fuel pump as far away from the battery as possible.

- Always switch the voltage on and off on the battery side, not the fuel pump side.

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE FUEL SENDER GAUGE

2. SEPARATE FUEL SUCTION PLATE SUB-ASSEMBLY

(a) Disconnect the fuel pump connector from the fuel suction plate.

NOTICE:

Do not ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FUEL PUMP ASSEMBLY WITH FILTER

HINT:

Perform "Inspection After Repair" after replacing the fuel pump (See page

).

(a) Apply gasoline to a ne ...

Other materials about Toyota Venza:

Front Passenger Side Door ECU Communication Stop (B2322)

DESCRIPTION

This DTC is stored when LIN communication between the power window regulator

motor assembly (for front passenger side) and main body ECU (driver side junction

block assembly) stops for more than 10 seconds.

DTC No.

DTC D ...

Back Door Courtesy Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

2. REMOVE BACK DOOR LOCK ASSEMBLY

(a) Disconnect the connector.

(b) Disengage the c ...

Engine Circuit Malfunction (C1280/82)

DESCRIPTION

If a malfunction in the ECM circuit occurs, the AWD control ECU will output this

DTC.

DTC No.

DTC Detection Condition

Trouble Area

C1280/82

When the following continues for ...

0.1656