Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE FUEL SENDER GAUGE

.gif)

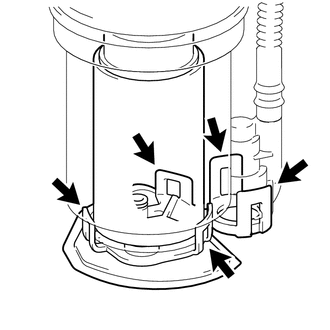

2. SEPARATE FUEL SUCTION PLATE SUB-ASSEMBLY

|

(a) Disconnect the fuel pump connector from the fuel suction plate. NOTICE: Do not damage the wire harness. |

|

|

(b) Using needle nose pliers, remove the E-ring. Text in Illustration

NOTICE: Do not disconnect the tube shown in the illustration when disassembling the fuel suction tube assembly with pump and gauge. Doing so will cause reassembly of the fuel suction tube assembly with pump and gauge to be impossible as the tube is welded to the plate. |

|

(c) Separate the fuel suction plate and remove the spring from the sub-tank.

3. REMOVE FUEL FILTER ASSEMBLY

|

(a) Disengage the 2 claws and remove the filter from the sub-tank. |

|

|

(b) Using a screwdriver with the tip taped, detach the claw of the jet pump nozzle. |

|

|

(c) Using a screwdriver with the tip taped, remove the jet pump from the sub-tank. |

|

|

(d) Remove the O-ring from the jet pump. Text in Illustration

|

|

4. REMOVE FUEL PUMP ASSEMBLY WITH FILTER

|

(a) Disengage the 5 claws on the filter and remove the fuel pump from the fuel filter. NOTICE:

HINT: If the fuel filter assembly is to be replaced, replace the fuel suction plate sub-assembly. |

|

|

(b) Disconnect the fuel pump connector from the fuel pump and then remove the fuel pump harness. |

|

|

(c) Remove the O-ring and spacer from the fuel pump. NOTICE: Be careful not to damage the sealing surface. HINT: If the O-ring still remains in the fuel filter, remove it using a wire tip (φ1 mm) that is formed as shown in the illustration. |

|

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the fuel pump assembly (See

page ).

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

(a) Discharge ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL PUMP ASSEMBLY WITH FILTER

(a) Inspect fuel pump resistance.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

...

Other materials about Toyota Venza:

Front Occupant Classification Sensor RH Circuit Malfunction (B1781)

DESCRIPTION

The front occupant classification sensor RH circuit consists of the occupant

classification ECU and front occupant classification sensor RH.

DTC B1781 is recorded when a malfunction is detected in the front occupant classification

sensor RH c ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FLUID LEVEL

(a) Check the fluid level.

Text in Illustration

*1

MAX Line

*2

MIN Line

HINT:

If brake ...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is output during the DTC check, inspect the trouble areas listed

for that code. For details of the code, refer to "See page" in the DTC chart.

Inspect the fuses and relays before troub ...

0.148

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)