Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE MAGNETIC CLUTCH ASSEMBLY

|

(a) Place the compressor and magnetic clutch in a vise. |

|

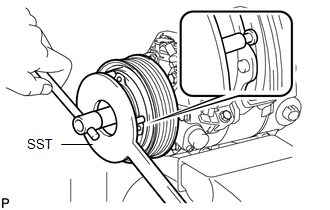

(b) Using SST, hold the magnetic clutch hub.

SST: 09985-00270

(c) Remove the bolt, magnetic clutch hub, and magnetic clutch washers.

HINT:

There is no set number of magnetic clutch washers because they are used for adjustment.

|

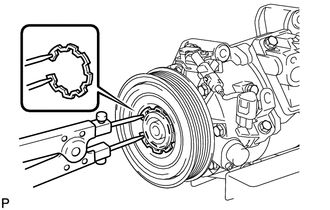

(d) Using a snap ring expander, remove the snap ring and then remove the magnetic clutch rotor. NOTICE: Take care not to damage the seal cover of the bearing when removing the snap ring. |

|

|

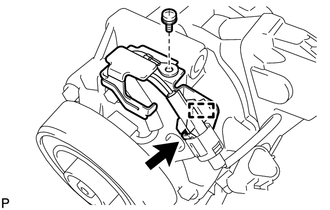

(e) Disconnect the connector. |

|

(f) Disengage the clamp.

(g) Remove the screw and the bracket.

|

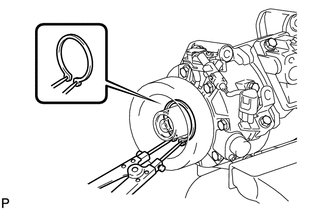

(h) Using a snap ring expander, remove the snap ring and magnetic clutch stator. NOTICE: Take care not to damage the seal cover of the bearing when removing the snap ring. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT COMPRESSOR AND MAGNETIC CLUTCH (A/C LOCK SENSOR)

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

...

Other materials about Toyota Venza:

Throttle / Pedal Position Sensor / Switch "D" Circuit Range / Performance (P2121)

DESCRIPTION

Refer to DTC P2120 (See page ).

HINT:

This DTC relates to the accelerator pedal sensor assembly.

DTC No.

DTC Detection Condition

Trouble Area

P2121

Either of following conditions 1 o ...

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT DOOR SCUFF PLATE LH

2. REMOVE COWL SIDE TRIM SUB-ASSEMBLY LH

3. REMOVE LOWER NO. 1 INSTRUMENT PANEL FINISH PANEL

4. REMOVE OUTER MIRROR SWITCH ASSEMBLY

(a) Disengage the 2 claws and remove the outer m ...

System Diagram

SYSTEM DIAGRAM

Communication Table

Sender

Receiver

Signal

Line

Main Body ECU

(Driver Side Junction Block Assembly)

Clearance Warning ECU Assembly

Destination information

...

0.1292