Toyota Venza: Inspection

INSPECTION

PROCEDURE

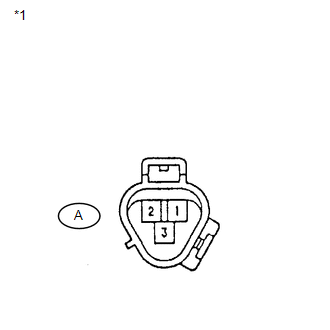

1. INSPECT COMPRESSOR AND MAGNETIC CLUTCH (A/C LOCK SENSOR)

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the resistance is not as specified, replace the compressor and magnetic clutch. Text in Illustration

|

|

2. INSPECT COMPRESSOR AND MAGNETIC CLUTCH (A/C COMPRESSOR SOLENOID)

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the resistance is not as specified, replace the compressor and magnetic clutch. Text in Illustration

|

|

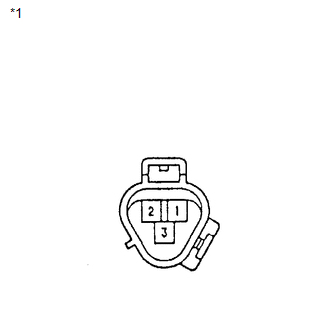

3. INSPECT COMPRESSOR AND MAGNETIC CLUTCH

|

(a) Disconnect the connector from the compressor and magnetic clutch. |

|

|

(b) Disconnect the connector from the magnetic clutch. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A-3 - B-1 |

Always |

Below 1 Ω |

|

A-3 - Body ground |

Always |

10 kΩ or higher |

If the resistance is not as specified, replace the compressor and magnetic clutch.

Text in Illustration|

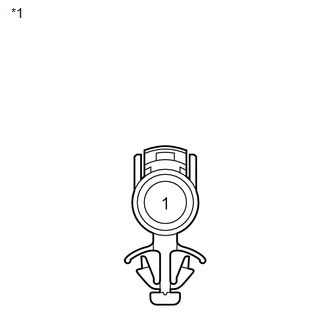

*1 |

Component without harness connected (A/C Compressor) |

|

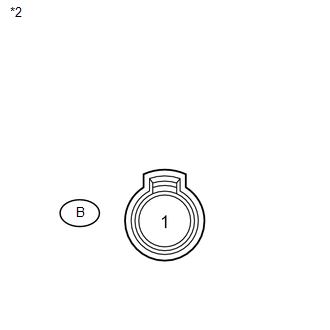

*2 |

Front view of wire harness connector (to Magnetic Clutch) |

4. INSPECT MAGNETIC CLUTCH

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the resistance is not as specified, replace the magnetic clutch. |

|

(b) When connector terminal 1 is connected to the positive (+) battery terminal, check that the following occurs: 1) the magnetic clutch's operating sound can be heard, and 2) the magnetic clutch's hub and rotor lock.

OK:

1)

The magnetic clutch's operating sound can be heard.

2)

The magnetic clutch's hub and rotor lock.

If the result is not as specified, replace the magnetic clutch.

Text in Illustration|

*1 |

Component without harness connected (Magnetic Clutch) |

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE MAGNETIC CLUTCH ASSEMBLY

(a) Place the compressor and magnetic clutch in a vise.

(b) Using SST, hold the m ...

Installation

Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN COMPRESSOR AND MAGNETIC CLUTCH

(a) Temporarily install the compressor and magnetic clutch and bracket

with the 4 bolts.

...

Other materials about Toyota Venza:

Power Back Door Closer Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

2. REMOVE POWER BACK DOOR CLOSER SWITCH ASSEMBLY

(a) Disconnect the connector.

(b) ...

Terminals Of Ecm

TERMINALS OF ECM

HINT:

The standard voltage between each pair of ECM terminals is shown in the table

below. The appropriate conditions for checking each pair of terminals are also indicated.

The result of checks should be compared with the standard vol ...

Removal

REMOVAL

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

(See page ).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

3. REMOV ...

0.1399

.png)